Yes, absolutely. Pyrolysis is a form of advanced, or chemical, recycling specifically designed to handle plastics. The process uses high temperatures in an oxygen-free environment to break down the complex molecular structure of plastics, converting them back into their core components: oil, gas, and a solid carbon char.

Pyrolysis effectively transforms plastic waste, particularly mixed and contaminated types that are unsuitable for traditional recycling, into valuable chemical feedstocks and fuel. However, the quality of the outputs and the economic viability of the process are highly dependent on the type of plastic used and the sophistication of the technology.

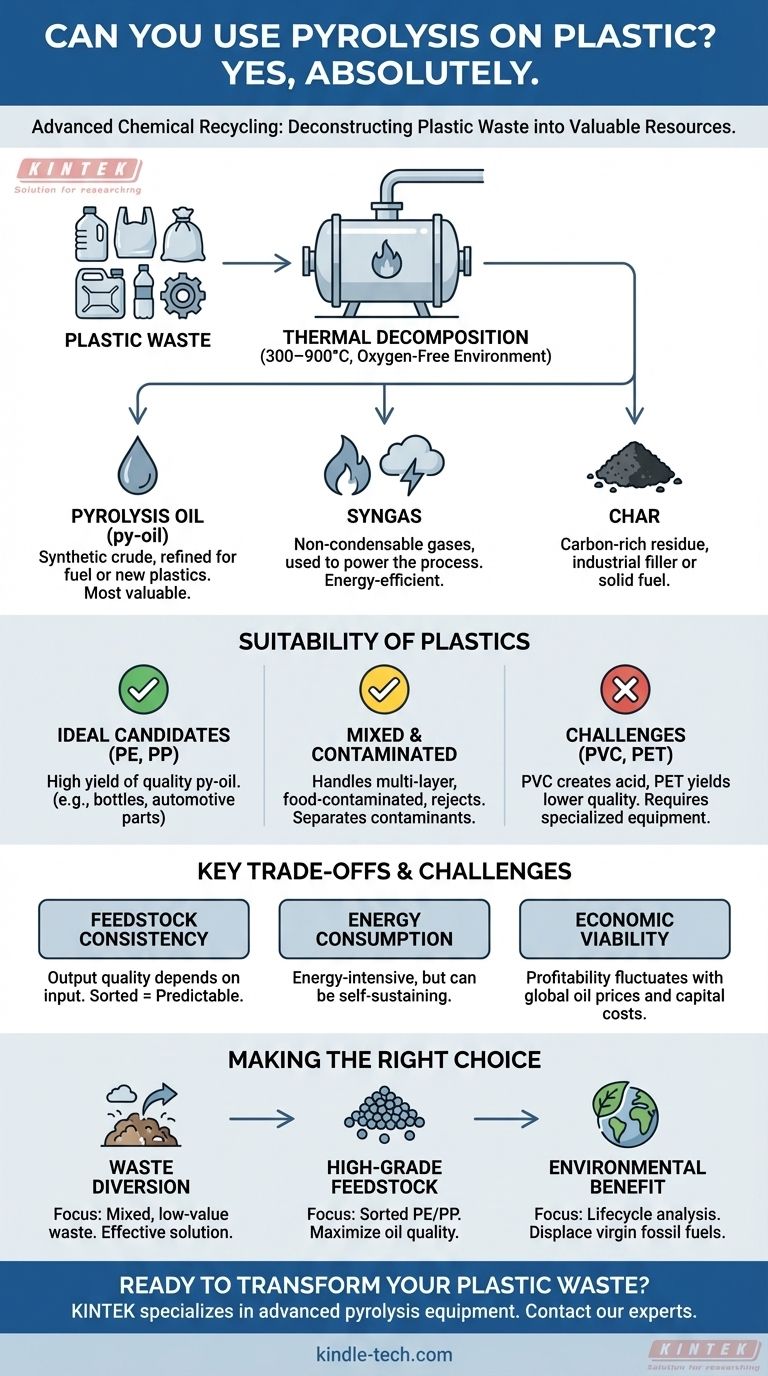

How Pyrolysis Deconstructs Plastic

The Core Principle: Thermal Decomposition

Pyrolysis is not burning. It is the thermal decomposition of materials at elevated temperatures (typically 300–900°C) in an inert atmosphere, meaning an environment without oxygen.

Without oxygen, the long polymer chains that make up plastic don't combust. Instead, they break apart, or "crack," into smaller, simpler hydrocarbon molecules.

From Solid Waste to Valuable Outputs

This decomposition process results in three primary products:

- Pyrolysis Oil (py-oil): A liquid synthetic crude oil that can be refined into diesel, gasoline, or used as a feedstock to create new plastics. This is often the most valuable output.

- Syngas: A mix of non-condensable gases (like hydrogen, methane, and carbon monoxide) that is typically captured and used to power the pyrolysis reactor itself, making the process more energy-efficient.

- Char: A solid, carbon-rich residue (similar to carbon black) that can be used as an industrial filler, a soil amendment, or as a solid fuel.

Why It's Different from Incineration

It is critical to distinguish pyrolysis from incineration. Incineration uses oxygen to burn waste, releasing its energy as heat and leaving behind ash. Pyrolysis uses a lack of oxygen to deconstruct waste into new chemical substances that can be used as raw materials.

Which Plastics Are Suitable for Pyrolysis?

The Ideal Candidates: Polyolefins

Plastics like Polyethylene (PE)—found in plastic bags and bottles—and Polypropylene (PP)—found in containers and automotive parts—are ideal feedstocks. Their simple chemical structure yields a high volume of quality py-oil.

Handling Mixed and Contaminated Plastics

A major advantage of pyrolysis is its ability to process waste streams that cripple mechanical recycling. This includes:

- Multi-layer packaging (like food pouches)

- Post-consumer mixed plastics

- Plastics contaminated with food, paper, or other materials

- Rejects from mechanical recycling facilities

By breaking the material down to its basic chemical level, these contaminants are either separated or incorporated into the less valuable char and gas outputs.

The Challenge with PVC and PET

While pyrolysis can handle mixed streams, certain plastics present challenges. Polyvinyl Chloride (PVC) contains chlorine, which can form corrosive hydrochloric acid during the process, requiring specialized and more expensive equipment to neutralize.

Similarly, oxygen-containing plastics like Polyethylene Terephthalate (PET) yield a lower-quality oil. While processing "mixed PET/PVC contaminated plastics" is technically possible, it often requires more advanced systems and pre-treatment to manage these problematic elements.

Understanding the Trade-offs and Challenges

Feedstock Consistency

While pyrolysis is robust, the output quality is directly tied to the input quality. A consistent feedstock of sorted PE and PP will produce a more valuable and predictable oil than a random mix of municipal plastic waste.

Energy Consumption

Pyrolysis is an energy-intensive process. The system's net energy balance is crucial; it must produce significantly more energy in its outputs (oil and gas) than it consumes to heat the reactor. Modern systems are designed to be self-sustaining by burning their own syngas output.

Economic Viability

The business case for pyrolysis hinges on the market value of its outputs. High capital costs for the equipment and ongoing operational expenses must be offset by the revenue from selling the pyrolysis oil and char. This viability can fluctuate with global oil prices.

Making the Right Choice for Your Goal

When considering pyrolysis, your primary objective will determine your approach.

- If your primary focus is diverting mixed, low-value plastic waste from landfill: Pyrolysis is an extremely effective solution, especially for materials that cannot be sorted or cleaned for traditional recycling.

- If your primary focus is producing high-grade chemical feedstock for new plastics: You must invest in pre-sorting to create a clean, homogenous feedstock of polyolefins (PE and PP) to maximize oil quality.

- If your primary focus is maximizing environmental benefit: You must perform a full lifecycle analysis, considering the energy source for the process, managing emissions, and ensuring the final products displace virgin fossil fuels.

Ultimately, pyrolysis serves as a powerful chemical recycling pathway that complements traditional methods by turning complex plastic waste back into a valuable resource.

Summary Table:

| Plastic Type | Suitability for Pyrolysis | Key Considerations |

|---|---|---|

| Polyethylene (PE), Polypropylene (PP) | Excellent | Ideal feedstock; yields high-quality oil. |

| Mixed/Contaminated Plastics | Good | Handles materials unsuitable for mechanical recycling. |

| PVC, PET | Challenging | Requires specialized equipment; can yield lower-quality outputs. |

Ready to transform your plastic waste into valuable resources?

KINTEK specializes in advanced pyrolysis equipment and consumables for laboratories and recycling facilities. Our solutions are designed to help you efficiently convert challenging plastic waste streams into profitable oil, gas, and char. Whether you're focused on waste diversion or producing high-grade feedstocks, we have the expertise and technology to support your goals.

Contact our experts today to discuss how our pyrolysis systems can enhance your recycling operations and contribute to a circular economy.

Visual Guide

Related Products

- Vertical Laboratory Tube Furnace

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What is the heat required for pyrolysis? Mastering Energy Input for Optimal Biochar, Bio-Oil, or Syngas

- What are the products of pyrolysis of biomass? Unlock Bio-Char, Bio-Oil, and Syngas

- How do you heat a pyrolysis reactor? Direct vs. Indirect Heating Methods Explained

- What are the uses of pyrolysis machine? Turn Waste into Fuel, Chemicals, and Soil Amendment

- What are the sources of pyrolysis oil? Unlock Fuel from Biomass & Plastic Waste

- What are the three stages of pyrolysis? Turn Waste into Biochar, Bio-Oil & Syngas

- What is the yield of biochar in slow pyrolysis? Maximize Your Output Up to 30%

- What is the temperature range for fast pyrolysis? Optimize Bio-Oil Yield from Biomass