Yes, but very inefficiently under normal conditions. Copper does heat up when exposed to a changing magnetic field, but its unique properties make it a poor material for standard induction heating applications like cookware. The reason is rooted in copper's extremely low electrical resistance, which is the very quality that makes it excellent for electrical wiring.

The core principle of induction is turning electrical current into heat. While an induction coil can easily create currents inside copper, copper's low resistance allows that current to flow with very little friction, generating minimal heat compared to materials like iron.

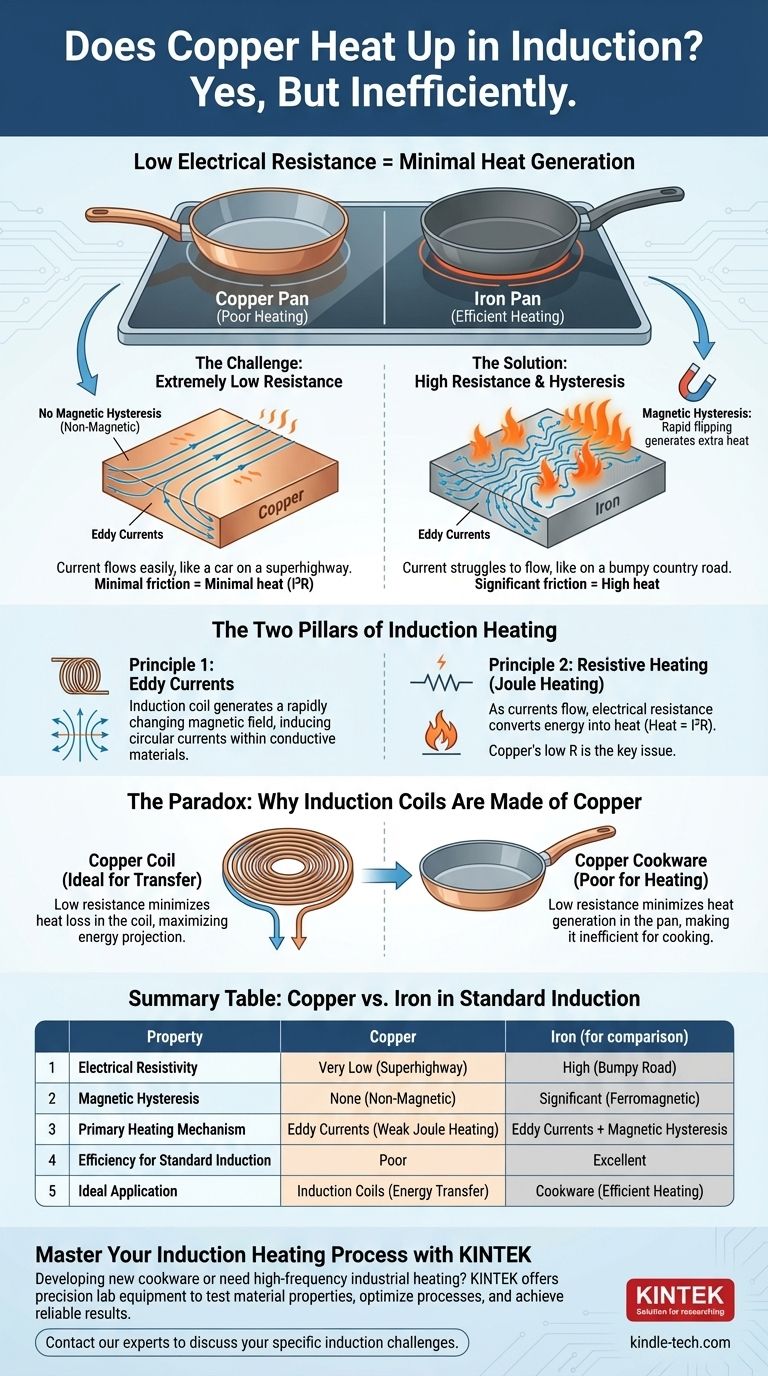

The Two Pillars of Induction Heating

To understand why copper is a poor choice, you must first understand the two primary mechanisms by which induction heating works.

Principle 1: Eddy Currents

An induction system uses a coil (typically made of copper) to generate a high-frequency, rapidly changing magnetic field.

When a conductive material like copper or iron is placed within this field, the magnetic field induces circular electrical currents within the material. These are called eddy currents.

Principle 2: Resistive Heating (Joule Heating)

As these eddy currents flow through the material, they encounter electrical resistance. This resistance acts like friction, converting the electrical energy into heat.

This process is known as Joule heating or resistive heating, governed by the formula Heat = I²R (Current squared times Resistance).

Why Copper Resists Induction Heating

While eddy currents are easily induced in copper, two key factors prevent it from heating effectively, especially at the lower frequencies used in consumer appliances like cooktops.

Extremely Low Electrical Resistivity

This is the primary reason. Copper has one of the lowest electrical resistivities of any common metal.

Think of it this way: electricity flows through copper like a car on a frictionless superhighway. It moves with almost no effort and generates very little "frictional" heat.

Iron, in contrast, has a much higher resistivity. It's like a bumpy country road for electricity. The current has to work much harder to move, generating significant friction and, therefore, a lot of heat.

The Absence of Magnetic Hysteresis

For ferromagnetic materials like iron, a powerful secondary heating effect occurs. The rapidly changing magnetic field forces the magnetic domains within the iron to flip back and forth billions of times per second.

This rapid flipping creates a huge amount of internal friction, generating even more heat. This effect is called magnetic hysteresis.

Because copper is not a magnetic material, it receives zero heating benefit from hysteresis, making it even less efficient compared to iron.

Understanding the Trade-offs

The interaction between a material and an induction field is not a simple yes/no question. The frequency of the magnetic field plays a critical role.

The Crucial Role of Frequency

It is possible to heat copper effectively with induction, but it requires a specialized system running at a much higher frequency than a standard induction cooktop.

Higher frequencies force the eddy currents into a very thin layer at the material's surface (a phenomenon called the skin effect). This concentrates the current and can overcome copper's low resistance to generate significant heat, which is how industrial induction forges can melt copper or aluminum.

The Paradox: Why Induction Coils Are Made of Copper

The very reason copper is poor for heating is what makes it the perfect material for the induction coil itself.

An efficient system needs the coil to transfer magnetic energy to the workpiece (the pan) with as little energy loss as possible. Because copper has low resistance, very little energy is wasted as heat in the coil, allowing almost all of it to be projected into the target material.

Making the Right Choice for Your Goal

Ultimately, whether a material is "good" for induction depends entirely on your objective.

- If your primary focus is efficient heating (like cookware): You must choose a ferromagnetic material with high electrical resistance and magnetic properties, such as cast iron or magnetic-grade stainless steel.

- If your primary focus is efficient energy transfer (the induction coil): You must choose a material with the lowest possible electrical resistance to minimize heat loss, which is why copper is the ideal choice.

- If your primary focus is industrial heating of non-ferrous metals: You must use a specialized induction system engineered to operate at the very high frequencies needed to heat materials like copper or aluminum effectively.

Understanding a material's fundamental electrical and magnetic properties is the key to mastering induction technology for any application.

Summary Table:

| Property | Copper | Iron (for comparison) |

|---|---|---|

| Electrical Resistivity | Very Low | High |

| Magnetic Hysteresis | None (Non-Magnetic) | Significant (Ferromagnetic) |

| Primary Heating Mechanism | Eddy Currents (Joule Heating) | Eddy Currents + Magnetic Hysteresis |

| Efficiency for Standard Induction | Poor | Excellent |

| Ideal Application | Induction Coils (Energy Transfer) | Cookware (Efficient Heating) |

Master Your Induction Heating Process with KINTEK

Whether you are developing new cookware or require high-frequency industrial heating for non-ferrous metals like copper, the right lab equipment is crucial. KINTEK specializes in precision lab equipment and consumables, providing the tools you need to test material properties, optimize your processes, and achieve reliable results.

Contact our experts today to discuss how our solutions can help you select the right materials and equipment for your specific induction heating challenges.

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What role does a vacuum hot pressing furnace play in silver-diamond composites? Achieve Peak Densification and Bonding

- Why is the vacuum system of a Vacuum Hot Pressing furnace critical for ODS ferritic stainless steel performance?

- How does the degassing stage in a vacuum hot press (VHP) optimize diamond/aluminum composite performance?

- How does using a Vacuum Hot Pressing Machine improve Copper-MoS2-Mo? Achieve Superior Material Density & Performance

- How does the mechanical pressure from a vacuum hot-pressing furnace facilitate the densification of B4C/Al composites?