Yes, PVD coating is exceptionally durable and designed to last for many years. Physical Vapor Deposition (PVD) is not a paint or traditional plating; it's an advanced process that creates a super-hard coating. This modern finish is by far the most durable coating available for watches today, offering superior quality that will significantly outlast older finishing methods.

The key to understanding PVD's longevity is recognizing that it's a molecular bond, not a simple layer. While it is highly resistant to wear and scratches, its ultimate lifespan is determined by the coating's thickness, the quality of the underlying steel, and how the watch is worn.

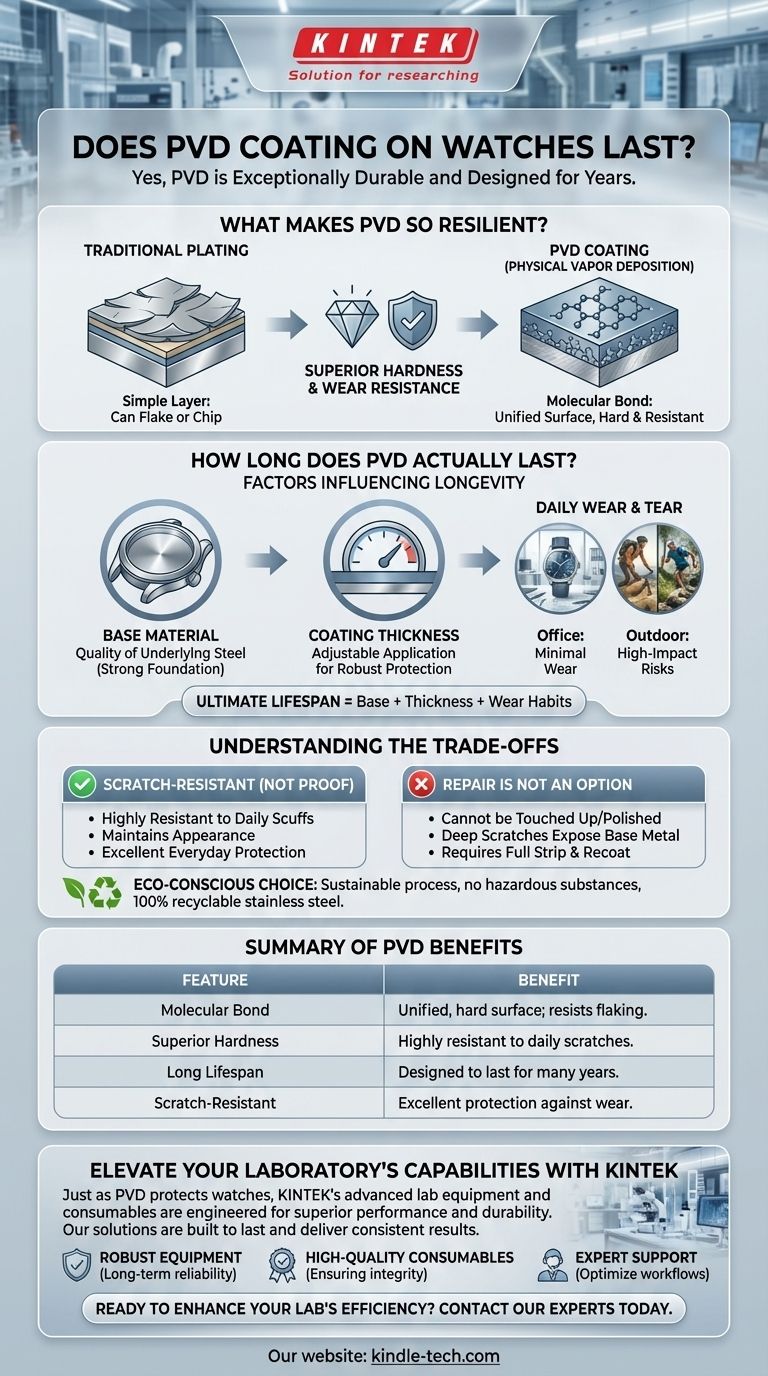

What Makes PVD So Resilient?

The durability of PVD coating comes from the unique way it is applied, which creates a finish that is fundamentally part of the watch's surface.

Not a Simple Layer of Paint

Unlike traditional plating that can flake or chip, PVD involves bonding a coating material to the watch case at a molecular level within a vacuum. This creates a unified surface that is incredibly hard and resistant to separation.

Superior Hardness and Wear Resistance

The resulting PVD finish is extremely hard, significantly increasing the watch's resistance to daily scratches and scuffs. This is why it maintains its color and finish far longer than other coating methods.

How Long Does PVD Actually Last?

While PVD is built for longevity, several factors influence its real-world lifespan.

The Importance of the Base Material

The PVD coating's durability is directly tied to the hardness of the material underneath it. When applied to high-grade materials like stainless steel, the coating has a strong, stable foundation that prevents dents and dings that could compromise the finish.

The Role of Coating Thickness

The PVD application process can be adjusted to create coatings of varying thicknesses. A thicker, well-applied coating will naturally offer a longer lifespan and more robust protection against wear and tear.

Impact of Daily Wear and Tear

A PVD watch worn in an office environment will show minimal wear over many years. A watch worn during high-impact activities, however, will be more susceptible to deep scratches or gauges that can penetrate the coating.

Understanding the Trade-offs

No coating is indestructible. Being an informed owner means understanding the practical limitations of PVD.

Scratch-Resistant vs. Scratch-Proof

PVD is highly scratch-resistant, not scratch-proof. A sharp impact or a scrape against a harder material (like rock or concrete) can still scratch or even remove the coating in the affected area.

Repair Is Not an Option

A significant drawback is that PVD coatings cannot be "touched up" or polished out like a scratch on bare stainless steel. If a deep scratch exposes the silver-colored steel beneath, the only true solution is to have the entire watch case professionally stripped and recoated, which is often impractical.

An Environmentally Conscious Choice

It is worth noting that the PVD process is considered sustainable. It does not use hazardous substances, and PVD-coated stainless steel components remain 100% recyclable, contributing to a circular economy.

Making the Right Choice for Your Watch

Your decision should align with your lifestyle and expectations for the watch.

- If your primary focus is a durable, stylish daily watch: A PVD coating is an excellent choice that will maintain its appearance for years with normal care.

- If you need a rugged "beater" watch for high-impact activities: Be prepared for the possibility of deep scratches that may expose the underlying metal over time.

- If your primary focus is a lifetime piece you can polish and refinish: A traditional, uncoated stainless steel watch may be a more suitable long-term option.

Ultimately, a quality PVD-coated watch offers a fantastic combination of modern aesthetics and robust, everyday durability.

Summary Table:

| Feature | Benefit |

|---|---|

| Molecular Bond | Creates a unified, hard surface that resists flaking and chipping. |

| Superior Hardness | Highly resistant to daily scratches and scuffs, maintaining appearance. |

| Long Lifespan | Designed to last for many years with proper care and normal use. |

| Scratch-Resistant | Not scratch-proof, but offers excellent protection against everyday wear. |

Elevate Your Laboratory's Capabilities with KINTEK

Just as a high-quality PVD coating protects and enhances a watch, KINTEK's advanced lab equipment and consumables are engineered for superior performance and durability. Whether you are conducting precise heat treatment processes or require reliable consumables for daily operations, our solutions are built to last and deliver consistent results.

We specialize in serving the diverse needs of modern laboratories. By partnering with KINTEK, you gain access to:

- Robust Equipment: Designed for long-term reliability and precision.

- High-Quality Consumables: Ensuring the integrity and accuracy of your experiments.

- Expert Support: Our team is dedicated to helping you optimize your workflows.

Ready to enhance your lab's efficiency and outcomes? Contact our experts today to discuss how KINTEK can support your specific requirements and help you achieve your research goals.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

- Split Chamber CVD Tube Furnace with Vacuum Station Chemical Vapor Deposition System Equipment Machine

People Also Ask

- What are the advantages of PECVD? Enable Low-Temperature, High-Quality Thin-Film Deposition

- What is plasma activated chemical vapour deposition method? A Low-Temperature Solution for Advanced Coatings

- How does RF power create plasma? Achieve Stable, High-Density Plasma for Your Applications

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition