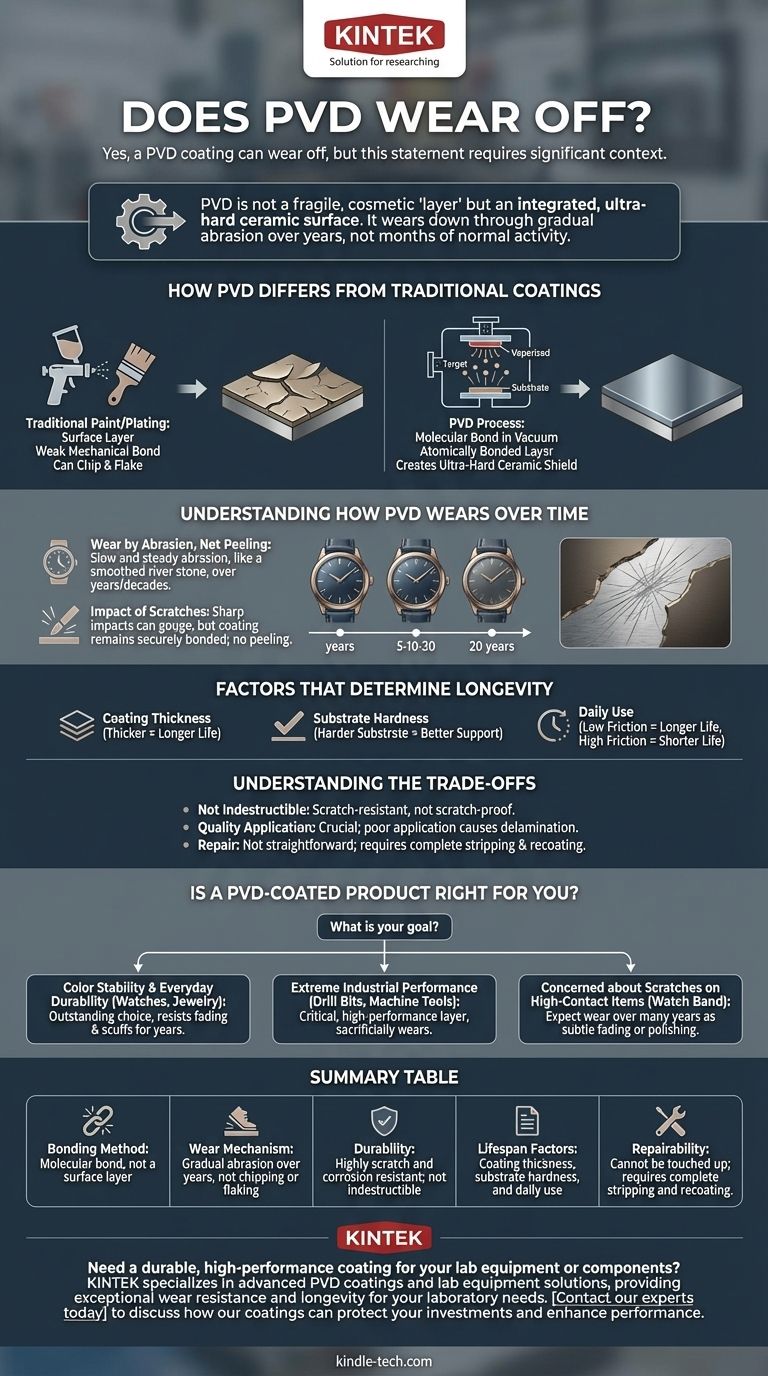

Yes, a PVD coating can wear off, but this statement requires significant context. Unlike paint or plating that can chip or flake away, a properly applied Physical Vapor Deposition (PVD) coating is a micro-thin ceramic layer that is molecularly bonded to the surface underneath. It wears down through gradual abrasion over a very long period, making it one of the most durable finishing processes available.

The core misunderstanding is thinking of PVD as a fragile, cosmetic "layer." It is better understood as an integrated, ultra-hard ceramic surface that is exceptionally resistant to daily wear, fading, and corrosion. Its eventual failure is measured in years or decades of abrasive use, not in months of normal activity.

How PVD Differs from Traditional Coatings

To understand how PVD wears, you must first understand what it is. The process does not involve any liquid paint or electro-chemical bath.

Not a "Finish," but a Molecular Bond

The PVD process takes place in a high-tech vacuum chamber. The base material, or substrate (e.g., stainless steel, titanium), is placed in the chamber, and a solid target of the coating material (like titanium or zirconium) is vaporized by a high-energy source.

These vaporized atoms then travel across the chamber and embed themselves into the substrate's surface, creating a new, atomically bonded layer. This is fundamentally different from paint, which simply dries on top of a surface and has a weak mechanical bond.

The Result: An Ultra-Hard Ceramic Layer

The materials used for PVD coatings, such as Titanium Nitride (TiN) or Diamond-Like Carbon (DLC), are ceramics. These materials are significantly harder than the steel or titanium they are applied to.

This creates a surface that is incredibly resistant to the scuffs and scratches of daily life. The PVD coating acts as a protective shield for the softer metal underneath.

Understanding How PVD Wears Over Time

Because PVD is bonded at a molecular level, it does not fail in the way most people expect.

Wear by Abrasion, Not Peeling

A PVD coating will not peel or flake off if it has been applied correctly. Instead, wear occurs through slow and steady abrasion—the same way a river stone is smoothed over centuries.

For a PVD-coated watch or faucet, this means it can withstand years of contact with skin, clothing, and cleaning without showing any visible wear. Only constant, high-friction contact with a harder material could gradually thin the coating.

The Impact of Scratches and Impacts

A sharp, heavy impact or a deep scratch from a material harder than the ceramic coating (like a diamond or sapphire) can gouge through the PVD layer and expose the substrate metal below.

However, even in this scenario, the surrounding PVD coating will remain securely bonded to the surface. It will not begin to peel away from the edges of the scratch.

Factors That Determine Longevity

The lifespan of a PVD coating is not fixed; it depends entirely on the application and quality.

- Coating Thickness: A thicker PVD application provides more material to wear through, extending its life.

- Substrate Hardness: A hard substrate like steel provides better support for the PVD coating than a soft one like aluminum. An impact on a soft metal can cause it to dent, potentially cracking the inflexible ceramic PVD layer above it.

- Daily Use: The PVD coating on a cutting tool used on hardened steel has a much shorter lifespan than the coating on a watch case, which may never see significant abrasive force.

Understanding the Trade-offs

While exceptionally durable, PVD is not an invincible material. Objectivity requires acknowledging its limitations.

PVD is Not Indestructible

No coating is completely scratch-proof. A sufficiently hard and sharp object can damage a PVD surface. It is highly scratch-resistant, not scratch-proof, which is an important distinction.

The Importance of Quality Application

The vast majority of PVD "failures" are actually due to poor application. If the substrate is not meticulously cleaned and prepared before entering the vacuum chamber, the atomic bond will be weak, which could lead to delamination. This, however, is a manufacturing defect, not a representation of normal wear.

Repair is Not Straightforward

You cannot "touch up" a damaged PVD coating. Repairing a deep scratch requires the entire part to be chemically stripped of the old coating, re-polished, and then completely re-coated. This is an intensive industrial process and is often not cost-effective for consumer goods.

Is a PVD-Coated Product Right for You?

Your decision should be based on a clear understanding of your goal for the product.

- If your primary focus is color stability and everyday durability (e.g., watches, jewelry, faucets): PVD is an outstanding choice that will resist fading and scuffs for many years, likely outlasting the functional life of the product itself.

- If your primary focus is extreme industrial performance (e.g., drill bits, machine tools): PVD is a critical, high-performance layer that is designed to be a consumable, sacrificially wearing away to protect the tool and improve its cutting efficiency.

- If you are concerned about scratches on a high-contact item (e.g., a metal watch band clasp): Expect that over many years, the points of highest contact may show wear as a subtle fading or polishing of the finish, not an unsightly chip or peel.

By understanding PVD as a durable, bonded surface rather than a simple finish, you can confidently assess its value for your specific needs.

Summary Table:

| PVD Coating Characteristic | Key Insight |

|---|---|

| Bonding Method | Molecular bond to substrate, not a surface layer |

| Wear Mechanism | Gradual abrasion over years, not chipping or flaking |

| Durability | Highly scratch and corrosion resistant; not indestructible |

| Lifespan Factors | Coating thickness, substrate hardness, and daily use |

| Repairability | Cannot be touched up; requires complete stripping and recoating |

Need a durable, high-performance coating for your lab equipment or components? KINTEK specializes in advanced PVD coatings and lab equipment solutions, providing exceptional wear resistance and longevity for your laboratory needs. Contact our experts today to discuss how our coatings can protect your investments and enhance performance.

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Silicon Carbide (SIC) Ceramic Sheet Wear-Resistant Engineering Advanced Fine Ceramics

- Molybdenum Disilicide (MoSi2) Thermal Elements Electric Furnace Heating Element

- Custom PTFE Teflon Parts Manufacturer for PTFE Tweezers

People Also Ask

- Is diamond coating permanent? The Truth About Its Long-Lasting Durability

- What are the three types of coating? A Guide to Architectural, Industrial, and Special Purpose

- How long does diamond coating last? Maximize Lifespan with the Right Coating for Your Application

- How thick is CVD diamond coating? Balancing Durability and Stress for Optimal Performance

- What is the process of CVD diamond coating? Grow a Superior, Chemically-Bonded Diamond Layer