Yes, a properly executed sintering process fundamentally increases the strength of a material. This is one of its primary objectives. Sintering transforms a collection of loose or lightly pressed powder particles, which has very low strength, into a solid, dense object by creating strong atomic bonds between the particles and significantly reducing the internal porosity that acts as a structural weak point.

The core purpose of sintering is to convert a mechanically weak powder compact into a dense, strong, and functional part. The increase in strength is not a side effect; it is the direct result of using thermal energy to eliminate pores and form a cohesive, bonded microstructure.

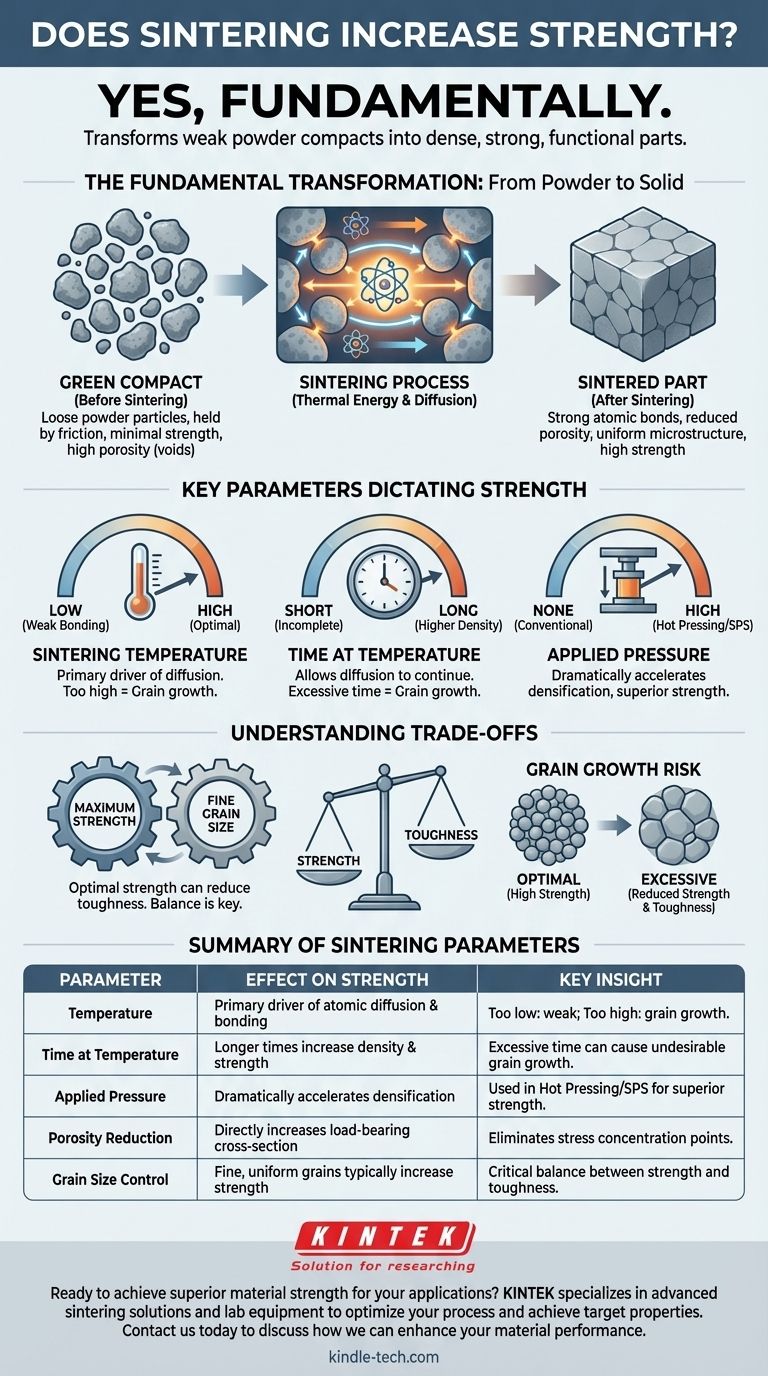

The Fundamental Mechanism: From Powder to Solid

A part formed from powder before sintering (a "green" compact) is held together only by friction and the interlocking of particles. It is brittle and has minimal strength. Sintering initiates a profound microstructural transformation that builds strength.

Eliminating Porosity

The most significant source of weakness in a powder compact is the empty space, or porosity, between the particles. These pores act as stress concentrators. When a load is applied, stress intensifies at the edges of these internal voids, leading to crack initiation and failure at very low overall forces.

Sintering drives material transport on an atomic level, causing particles to fuse and the pores between them to shrink and eventually close. Reducing this porosity drastically increases the cross-sectional area that can carry a load, directly translating to higher strength.

Creating Atomic Bonds

At sintering temperatures—which are below the material's melting point—atoms become highly mobile. This mobility allows atoms to diffuse across the contact points between individual powder particles.

This process, known as diffusion bonding, creates continuous, strong metallic or ceramic bonds. The initial weak, physical contact points are replaced by a unified grain structure, turning the collection of separate particles into a single, cohesive solid.

Controlling the Microstructure

Beyond just densification, sintering determines the final microstructure of the material, including its grain size and shape. These are critical factors that influence mechanical properties.

By carefully controlling the sintering process, you can engineer a fine, uniform grain structure. In many materials, a finer grain size correlates with higher strength and hardness according to principles like the Hall-Petch relationship.

Key Parameters That Dictate Final Strength

Achieving the desired strength is not automatic. It depends on precise control over the sintering process parameters, which directly influence the rate of densification and final microstructure.

Sintering Temperature

Temperature is the primary driver of diffusion. If the temperature is too low, atoms will not be mobile enough to facilitate bonding and pore closure, resulting in a weak, porous part. If it's too high, it can lead to excessive grain growth or even localized melting, which can be detrimental to the final properties.

Time at Temperature (Holding Time)

The duration of the sintering process at peak temperature allows diffusion to continue. A longer holding time generally leads to higher density and strength. However, similar to temperature, excessive time can also cause undesirable grain growth.

Applied Pressure

Some advanced sintering techniques, like Hot Pressing or Spark Plasma Sintering (SPS), apply external pressure during heating. This pressure physically forces particles together, breaking down surface oxides and dramatically accelerating the densification process. This often results in superior density and strength compared to conventional, pressureless sintering.

Understanding the Trade-offs

Optimizing for strength alone can lead to compromises in other areas. A successful engineering outcome depends on understanding these balances.

Strength vs. Toughness

The conditions that yield maximum strength, such as achieving the smallest possible grain size, can sometimes reduce a material's ductility or toughness (its ability to absorb energy and deform without fracturing). The ideal microstructure is often a compromise tailored to the specific application's demands.

The Risk of Excessive Grain Growth

The primary challenge in many sintering operations is to achieve full density without causing significant grain growth. Large grains can, in many cases, decrease strength and fracture toughness. This is why controlling temperature and time is so critical.

The Cost of Full Density

While higher density almost always means higher strength, achieving 100% of the material's theoretical density can be difficult and expensive. For many applications, reaching 92-98% density provides a strength level that is more than sufficient, offering a better balance between performance and manufacturing cost.

How to Apply This to Your Goal

Your approach to sintering should be guided by the specific mechanical properties your final component requires.

- If your primary focus is maximum strength and hardness: Prioritize achieving the highest possible density with a fine, uniform grain structure. This may require higher temperatures, longer times, or the use of pressure-assisted sintering techniques.

- If your primary focus is cost-effective production: Target a level of density that meets the minimum strength specifications for the application. Avoid the additional time and energy costs associated with pushing for near-full density if it is not required.

- If your primary focus is a balance of strength and toughness: Carefully control the sintering cycle to achieve sufficient densification while actively preventing excessive grain growth, as this often yields the best combination of properties.

By mastering these principles, you can intentionally design a material's internal structure to deliver the precise performance you need.

Summary Table:

| Sintering Parameter | Effect on Strength | Key Insight |

|---|---|---|

| Temperature | Primary driver of atomic diffusion and bonding | Too low: weak bonding; Too high: grain growth/melting |

| Time at Temperature | Longer times increase density and strength | Excessive time can cause undesirable grain growth |

| Applied Pressure | Dramatically accelerates densification | Used in techniques like Hot Pressing/SPS for superior strength |

| Porosity Reduction | Directly increases load-bearing cross-section | Eliminates stress concentration points from internal voids |

| Grain Size Control | Fine, uniform grains typically increase strength | Critical balance between strength and toughness |

Ready to achieve superior material strength for your applications?

At KINTEK, we specialize in providing advanced sintering solutions and lab equipment that help you precisely control material properties. Whether you need maximum strength, cost-effective production, or a balance of strength and toughness, our expertise in thermal processing can help you optimize your sintering parameters.

Our team can help you:

- Select the right sintering equipment for your specific material requirements

- Develop optimized sintering cycles to achieve your target density and microstructure

- Balance mechanical properties to meet your application's performance needs

Contact us today to discuss how we can enhance your material performance through precision sintering. Get in touch with our experts to start optimizing your process!

Visual Guide

Related Products

- Mesh belt controlled atmosphere furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Heat Treat and Pressure Sintering Furnace for High Temperature Applications

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Spark Plasma Sintering Furnace SPS Furnace

People Also Ask

- What is the role of an atmosphere-controlled tube furnace in Cu-Mo sintering? Achieve High-Purity Densification

- What is the core function of a high-temperature atmosphere sintering furnace in the fabrication of Ni-Al2O3-TiO2 composites?

- Why is a horizontal tube furnace with a H2-N2 atmosphere used for NiO pre-treatment? Key to Catalyst Activation

- How does an atmosphere furnace ensure quality in BN nanotube synthesis? Precision Control for Cup-Stacked Structures

- What is the function of a tube atmosphere furnace in Li2MnSiO4 synthesis? Achieve High-Purity Battery Materials