Yes, the primary purpose of sintering is to reduce porosity and increase the density of a material. This process works by heating a compacted powder to a high temperature, below its melting point, which causes the individual particles to bond together and shrink the empty spaces, or pores, between them.

Sintering fundamentally transforms a loose collection of particles into a solid, coherent mass. It leverages thermal energy to drive atomic diffusion, which systematically closes the voids between particles, leading to densification.

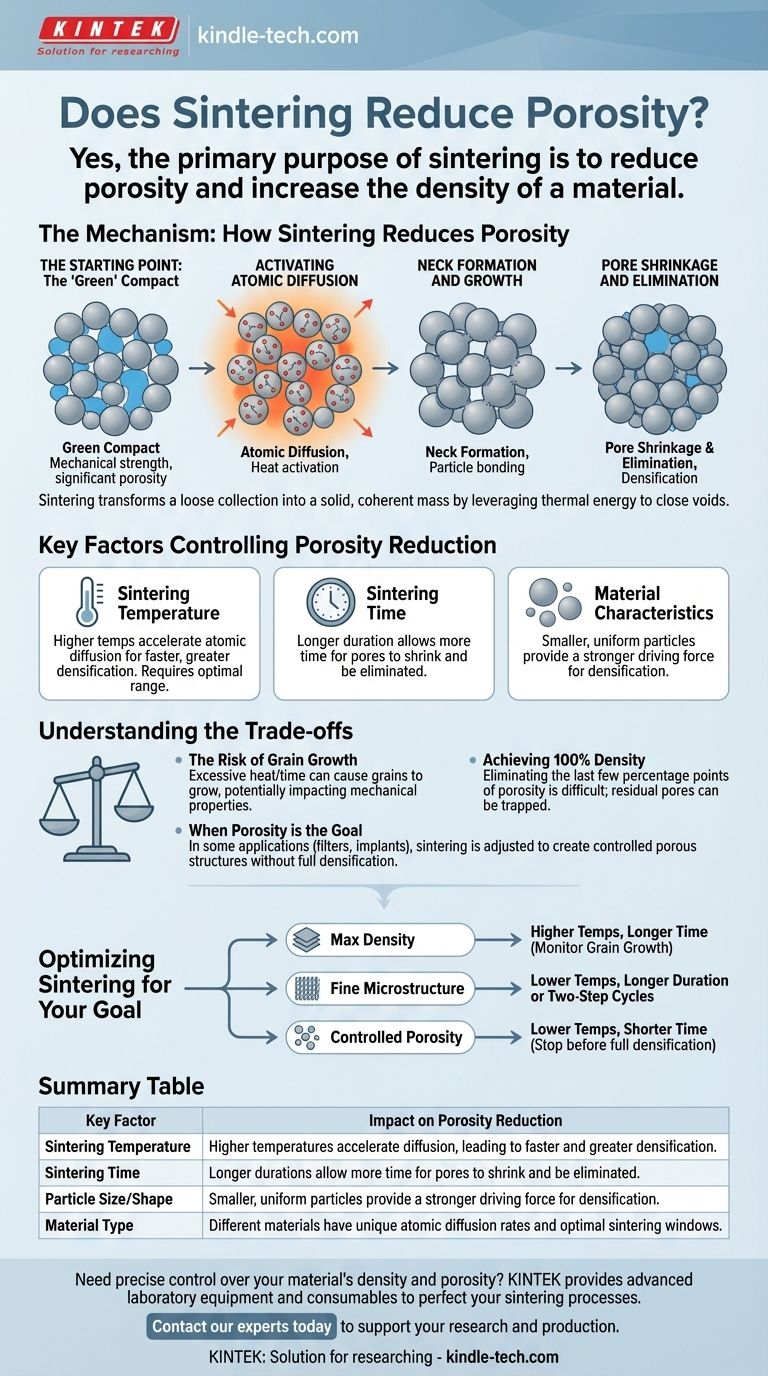

The Mechanism: How Sintering Reduces Porosity

Understanding sintering is about visualizing a process of particles bonding and voids shrinking. It occurs in distinct but overlapping stages, all driven by heat.

The Starting Point: The "Green" Compact

Before sintering, particles are typically pressed into a desired shape. This object, known as a "green" compact, has mechanical strength but contains a significant amount of empty space (porosity) between the particles.

Activating Atomic Diffusion

When the green compact is heated, the atoms within the particles gain thermal energy and become mobile. This atomic diffusion is the engine of sintering, allowing material to move and reshape the structure.

Neck Formation and Growth

Atoms migrate to the points of contact between adjacent particles. This movement of material builds small "necks" or bridges between them. As sintering progresses, these necks grow wider, pulling the centers of the particles closer together.

Pore Shrinkage and Elimination

The direct result of particles drawing closer is that the voids between them shrink. Initially interconnected pore networks break down into smaller, isolated pores. With sufficient time and temperature, these pores can be eliminated entirely as they migrate to the surface of the material, leading to a nearly fully dense part.

Key Factors Controlling Porosity Reduction

The effectiveness of sintering is not automatic; it is a carefully controlled process. As the reference indicates, key parameters like temperature and time dictate the final outcome.

Sintering Temperature

Temperature is the most critical factor. Higher temperatures provide more energy for atomic diffusion, accelerating neck growth and densification. However, there is an optimal range for every material.

Sintering Time

The duration of the sintering process also plays a crucial role. A longer hold time at the peak temperature allows more time for diffusion to occur, leading to greater porosity reduction.

Material Characteristics

The initial particle size, shape, and distribution significantly impact the process. Smaller, more uniform particles have higher surface energy, which provides a stronger driving force for densification.

Understanding the Trade-offs

While sintering is highly effective, it involves balancing competing phenomena to achieve the desired material properties.

The Risk of Grain Growth

The same thermal energy that drives densification also causes grains within the material to grow larger. Excessive grain growth can sometimes be detrimental to mechanical properties like strength and toughness. The goal is often to maximize density while minimizing grain growth.

Achieving 100% Density

Eliminating the last few percentage points of porosity is notoriously difficult. These residual pores can be trapped within grains, making them hard to remove through conventional sintering alone. Advanced techniques are sometimes required for full densification.

When Porosity is the Goal

In some advanced applications, such as for filters, bone implants, or self-lubricating bearings, the objective is not to eliminate porosity but to create a specific, controlled porous structure. In these cases, sintering parameters are adjusted to create bonds without full densification.

Optimizing Sintering for Your Goal

Controlling the outcome of sintering requires aligning the process parameters with your specific engineering objective.

- If your primary focus is maximum density: You will need to use higher temperatures and longer times, while carefully monitoring for excessive grain growth.

- If your primary focus is preserving a fine microstructure: Consider using lower temperatures for a longer duration or employing advanced two-step sintering cycles.

- If your primary focus is creating a controlled porous structure: You will operate at lower temperatures and shorter times, stopping the process before full densification is achieved.

Mastering these principles allows you to precisely engineer a material's internal structure to meet its final performance requirements.

Summary Table:

| Key Factor | Impact on Porosity Reduction |

|---|---|

| Sintering Temperature | Higher temperatures accelerate atomic diffusion, leading to faster and greater densification. |

| Sintering Time | Longer durations allow more time for pores to shrink and be eliminated. |

| Particle Size/Shape | Smaller, uniform particles provide a stronger driving force for densification. |

| Material Type | Different materials have unique atomic diffusion rates and optimal sintering windows. |

Need precise control over your material's density and porosity?

The principles of sintering are critical for developing high-performance materials. At KINTEK, we specialize in providing the advanced laboratory equipment and consumables necessary to perfect your sintering processes. Whether you are aiming for maximum density, a controlled porous structure, or a fine microstructure, our solutions are designed to meet your specific laboratory needs.

Let us help you achieve your material engineering goals. Contact our experts today to discuss how KINTEK can support your research and production with reliable, high-performance lab equipment.

Visual Guide

Related Products

- Dental Porcelain Zirconia Sintering Ceramic Furnace Chairside with Transformer

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Vacuum Heat Treat and Sintering Furnace with 9MPa Air Pressure

- Spark Plasma Sintering Furnace SPS Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

People Also Ask

- What makes zirconia translucent? The Science Behind Modern Dental Aesthetics

- Can you change the color of zirconia crowns? Understanding the Permanent Nature of Zirconia

- What is the price of zirconia sintering furnace? Invest in Precision, Not Just a Price Tag

- What is the sintering time for zirconia? A Guide to Precise Firing for Optimal Results

- What are the white spots on zirconia after sintering? A Guide to Diagnosing and Preventing Defects