For projects requiring high-fidelity prototypes and low-volume production runs, vacuum casting is a remarkably accurate process. It typically achieves a dimensional tolerance of ±0.3% of the nominal dimension. For smaller parts, a common baseline tolerance is approximately ±0.15 mm on the first millimeter.

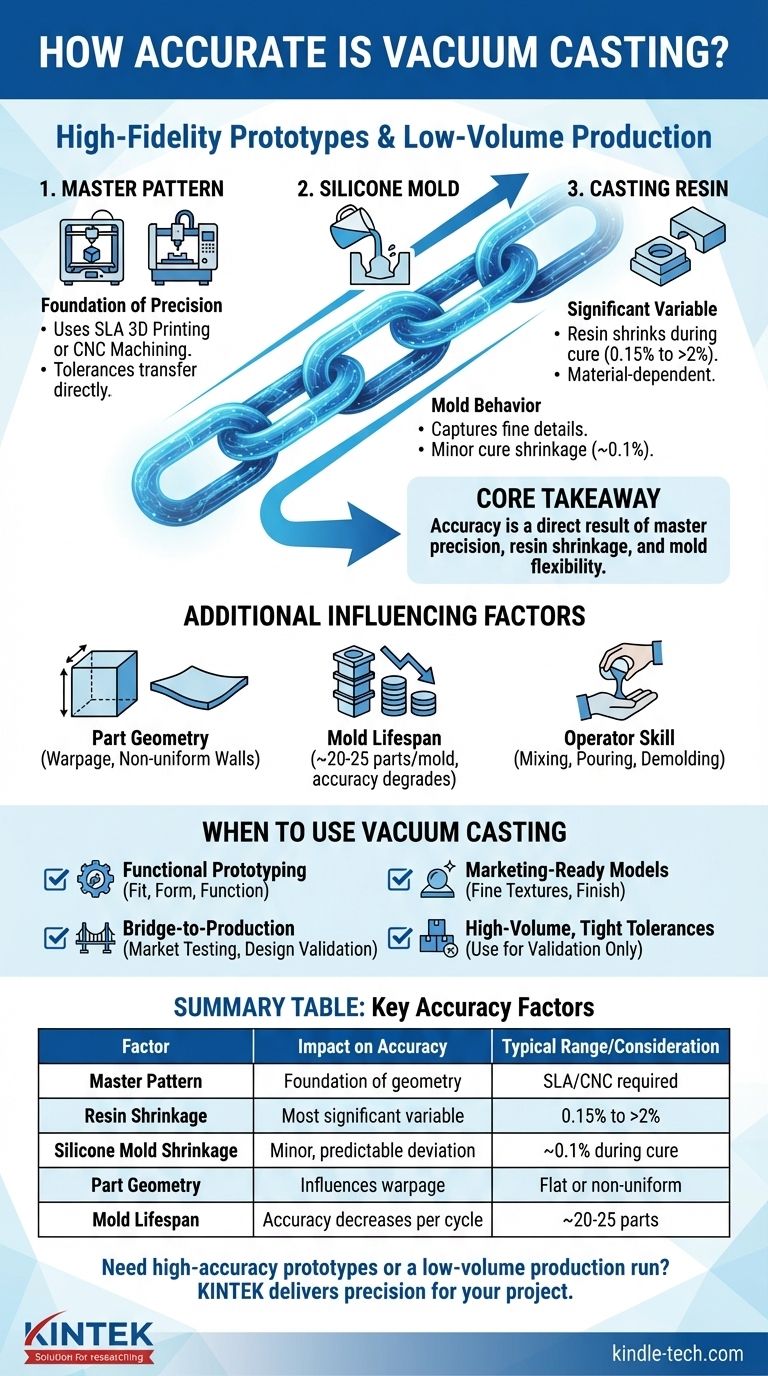

The core takeaway is that vacuum casting's accuracy is not a single number, but a direct result of three key factors: the precision of the master pattern, the predictable shrinkage of the casting resin, and the inherent flexibility of the silicone mold.

What Governs Vacuum Casting Accuracy?

To truly understand if the process is right for your part, you must look at the variables that contribute to the final dimensions. The precision is a chain of dependencies, starting with your master model.

The Master Pattern: Your Foundation of Precision

The final cast part can never be more accurate than the master pattern used to create the mold. This initial model is the source of all subsequent geometry.

High-precision methods like SLA (Stereolithography) 3D printing or CNC machining are used to create the master. The tolerances of this initial step directly carry over into the final product.

Silicone Mold Behavior

A liquid silicone rubber is poured around the master pattern to create the mold. While this material is excellent at capturing fine surface details, it has its own physical behaviors.

The silicone itself undergoes a small amount of shrinkage as it cures, typically around 0.1%. This is factored into the design, but it is a source of minor deviation.

Casting Resin Shrinkage

This is often the most significant factor affecting dimensional accuracy. The polyurethane resins used in vacuum casting shrink as they undergo a chemical reaction to cure and solidify.

Material manufacturers provide data sheets specifying the shrinkage rate for each resin, which can range from 0.15% to over 2%. Experienced technicians account for this, but it remains a critical variable.

Part Geometry and Size

The design of your part plays a direct role in its final accuracy.

Large, flat parts are more susceptible to warpage, while parts with non-uniform wall thicknesses can have varied shrinkage, leading to internal stresses and minor distortion.

Understanding the Trade-offs

Vacuum casting provides an exceptional balance of features, but it's crucial to recognize its limitations relative to other processes.

Accuracy vs. Mold Lifespan

A single silicone mold can typically produce 20-25 parts. However, the mold degrades slightly with each casting cycle.

This means the 20th part pulled from a mold may have slightly looser tolerances and less crisp detail than the first part. For consistent accuracy across a run, new molds may be required.

It's Not a Replacement for Hard Tooling

Vacuum casting is not a direct substitute for high-volume injection molding. Injection molding uses robust steel tools that can produce hundreds of thousands of highly repeatable parts with tighter tolerances.

The trade-off is cost and speed. A steel tool is orders of magnitude more expensive and time-consuming to create than a silicone mold.

The Influence of Operator Skill

The process involves a significant degree of human skill. Proper mixing of the resin, a controlled pour, and careful demolding all rely on an experienced technician to minimize variability and ensure the best possible outcome.

Is Vacuum Casting Accurate Enough for Your Project?

Use these guidelines to determine if the process fits your specific goal.

- If your primary focus is functional prototyping: Vacuum casting is an excellent choice, as its accuracy is more than sufficient for fit, form, and function testing with production-grade materials.

- If your primary focus is creating marketing-ready models: Its ability to replicate fine textures and produce a flawless surface finish makes it a superior option.

- If your primary focus is a bridge-to-production run: It is ideal for producing a few hundred parts to test the market or validate a design before committing to expensive steel tooling for injection molding.

- If your primary focus is high-volume manufacturing with very tight tolerances: You should plan to use vacuum casting for validation and then transition to injection molding or CNC machining for mass production.

By understanding these factors, you can confidently leverage vacuum casting's unique balance of speed, material quality, and precision for your application.

Summary Table:

| Factor | Impact on Accuracy | Typical Range/Consideration |

|---|---|---|

| Master Pattern | Foundation of all geometry | SLA 3D printing or CNC machining required |

| Resin Shrinkage | Most significant variable | 0.15% to over 2% (depends on material) |

| Silicone Mold Shrinkage | Minor, predictable deviation | ~0.1% during cure |

| Part Geometry | Influences warpage and distortion | Large, flat areas or non-uniform walls are challenging |

| Mold Lifespan | Accuracy decreases slightly per cycle | ~20-25 parts per mold for consistent quality |

Need high-accuracy prototypes or a low-volume production run?

Vacuum casting from KINTEK delivers the precision you need for functional testing and market-ready models. Our expertise in lab equipment and consumables ensures your project benefits from optimal material selection and skilled technique.

Let's discuss your specific tolerance requirements and project goals. Contact our experts today to see if vacuum casting is the right solution for you!

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Vacuum Dental Porcelain Sintering Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Graphite Vacuum Continuous Graphitization Furnace

People Also Ask

- How does hot pressing work? Achieve Maximum Density for Advanced Materials

- Which features of vacuum hot pressing equipment are utilized by the dual-step vacuum hot press process? Optimize AlMgTi

- What is hot press moulding? Achieve Superior Density and Complex Shapes with Heat and Pressure

- Why is a heated laboratory hydraulic press necessary for composite laminates? Achieve Void-Free Structural Integrity

- Why is a vacuum hot-pressing furnace preferred for C_fiber/Si3N4 composites? Achieve High Density & Fiber Protection