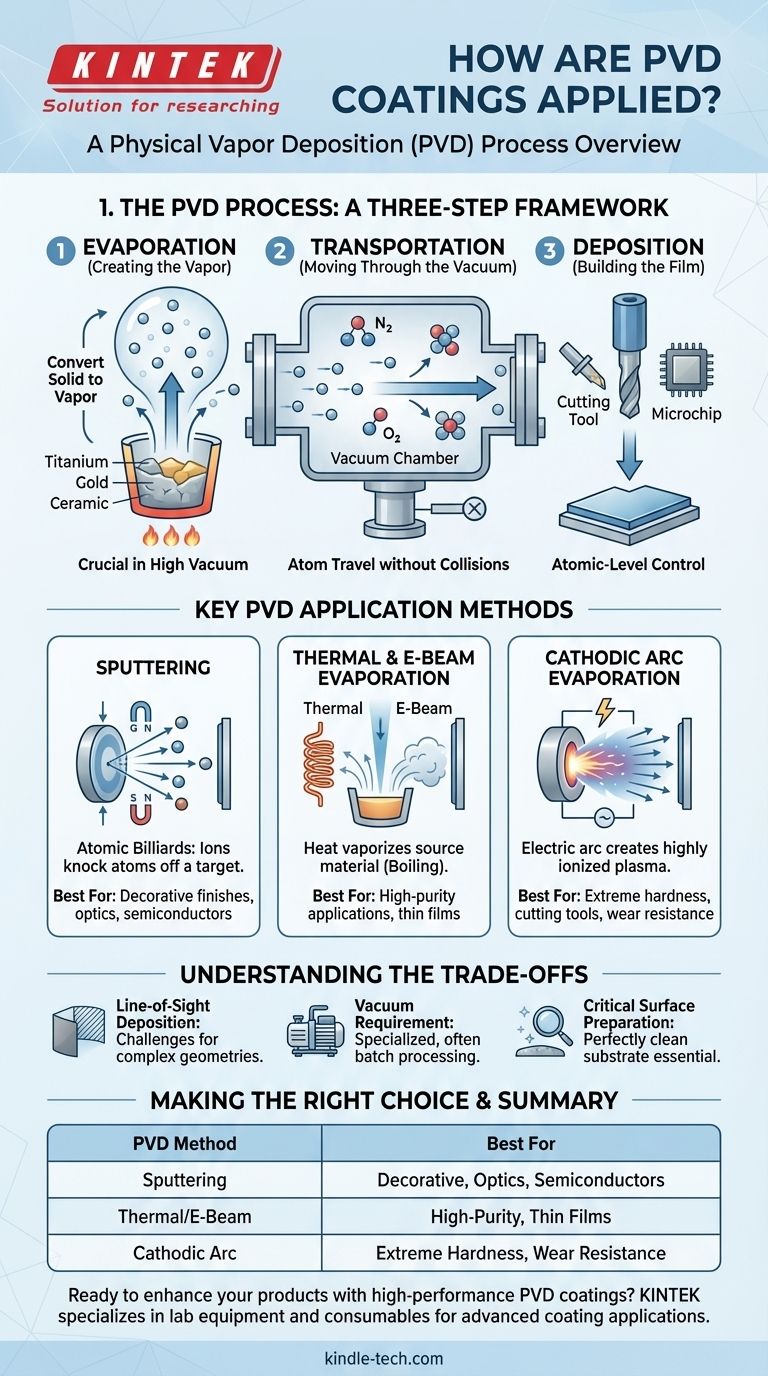

At its core, Physical Vapor Deposition (PVD) is a coating process conducted in a high-vacuum chamber. The method involves three fundamental steps: converting a solid coating material into a vapor, transporting that vapor across the chamber, and having it condense onto the target object, building a new surface layer one atom or molecule at a time. This atomic-level control is what allows for the creation of extremely pure, thin, and high-performance films.

The crucial takeaway is that PVD is not a single technique but a family of vacuum-based processes. All share the same principle of vaporizing a material to deposit a highly controlled thin film, but different methods are used to create that vapor, each offering unique advantages for specific applications.

The PVD Process: A Three-Step Framework

Understanding PVD is simplest when you break it down into its three universal stages. Every PVD method, from sputtering to evaporation, follows this same fundamental path inside a vacuum chamber.

Step 1: Evaporation (Creating the Vapor)

The first step is to convert the solid source material—such as titanium, gold, or ceramic—into a gaseous vapor. The vacuum is critical here, as it ensures the vapor doesn't react with air or other contaminants.

The specific method used to generate this vapor is what primarily distinguishes one PVD technique from another.

Step 2: Transportation (Moving Through the Vacuum)

Once created, the vaporized material travels through the vacuum chamber from the source to the target object, known as the substrate.

Because there are very few atoms or molecules in the vacuum, the vapor can travel in a straight line without collisions, ensuring a pure transfer of material. Sometimes, a reactive gas like nitrogen or oxygen is introduced to form a compound coating (like titanium nitride) on the substrate's surface.

Step 3: Deposition (Building the Film)

When the vapor particles reach the substrate, they condense back into a solid state. This forms a thin, tightly bonded film on the surface of the object.

This deposition happens at an atomic level, allowing for incredibly precise control over the coating's thickness, density, and structure.

Key PVD Application Methods

While the framework is consistent, the method used for the "Evaporation" step defines the process. Different methods are chosen based on the desired coating properties, material, and application.

Sputtering

Think of sputtering as atomic billiards. High-energy ions are fired at the source material (the "target"). These ions act like cue balls, knocking atoms off the target's surface.

These ejected atoms then travel across the chamber and deposit onto the substrate. Magnetron sputtering uses powerful magnets to trap electrons near the target, increasing the efficiency of this process.

Thermal & E-Beam Evaporation

This method is more intuitive—it uses heat to "boil" the coating material until it evaporates, much like boiling water creates steam.

Thermal evaporation uses an electrical resistive heating element. Electron-beam (e-beam) evaporation is more precise, using a focused beam of electrons in a high vacuum to heat and vaporize the source material.

Cathodic Arc Evaporation

This is a high-energy process that uses a powerful electric arc to strike the surface of the source material. The arc blast vaporizes a small spot of the material, creating a highly ionized plasma.

This ionized vapor is drawn to the substrate, resulting in an exceptionally dense and strongly adhered coating, making it ideal for high-wear applications like cutting tools.

Understanding the Trade-offs

PVD offers remarkable benefits but comes with specific operational requirements and limitations that are important to understand.

Line-of-Sight Deposition

PVD is primarily a line-of-sight process. The coating material travels in a straight line, which can make it challenging to evenly coat complex internal geometries or the backsides of objects without rotating them.

However, PVD processes generally offer better step coverage (the ability to coat sharp corners and small features) than some other vacuum methods.

Vacuum Requirement

The entire process must take place in a high-vacuum chamber. This requires specialized, often expensive, equipment and typically involves batch processing rather than a continuous flow.

Critical Surface Preparation

The substrate's surface must be perfectly clean for the PVD coating to adhere properly. Any microscopic contaminants like dust or oil will create defects in the film, so a rigorous pre-cleaning process is essential.

Making the Right Choice for Your Goal

Selecting the right PVD method depends entirely on the intended outcome for the final product, whether it's for durability, purity, or aesthetics.

- If your primary focus is extreme purity and precision (optics, semiconductors): Sputtering or e-beam evaporation are the preferred methods due to their fine control over film thickness and composition.

- If your primary focus is maximum hardness and wear resistance (cutting tools, industrial parts): Cathodic arc evaporation is often the best choice for creating the densest, most durable, and best-adhered coatings.

- If your primary focus is decorative and protective finishes (jewelry, fixtures, consumer products): Sputtering is highly versatile and cost-effective for applying a wide range of colors and materials like gold or titanium nitride.

By understanding these core principles, you can effectively choose the precise PVD technique to achieve your specific performance and aesthetic goals.

Summary Table:

| PVD Method | Key Principle | Best For |

|---|---|---|

| Sputtering | Atomic billiards: ions knock atoms off a target | Decorative finishes, optics, semiconductors |

| Thermal/E-Beam Evaporation | Heat vaporizes the source material | High-purity applications, thin films |

| Cathodic Arc Evaporation | Electric arc creates highly ionized plasma | Extreme hardness, cutting tools, wear resistance |

Ready to enhance your products with high-performance PVD coatings? KINTEK specializes in lab equipment and consumables for advanced coating applications. Whether you're developing wear-resistant tools, precision optics, or decorative finishes, our expertise and solutions can help you achieve superior results. Contact our team today to discuss your specific needs and discover how we can support your laboratory's success.

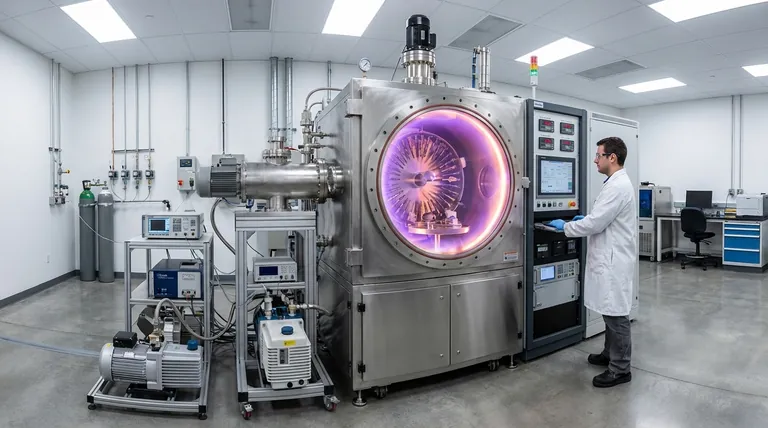

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- VHP Sterilization Equipment Hydrogen Peroxide H2O2 Space Sterilizer

People Also Ask

- What is plasma enhanced chemical vapour deposition process? Unlock Low-Temperature, High-Quality Thin Films

- What materials are deposited in PECVD? Discover the Versatile Thin-Film Materials for Your Application

- What is plasma in CVD process? Lowering Deposition Temperatures for Heat-Sensitive Materials

- How does plasma enhanced CVD work? Achieve Low-Temperature, High-Quality Thin Film Deposition

- What is plasma enhanced chemical vapor deposition? Achieve Low-Temperature, High-Quality Thin Films