Reducing the power consumption of an induction furnace is achieved by systematically minimizing energy losses and optimizing the melting process. The most effective strategies involve improving the quality and density of the charge material, maintaining the furnace's physical integrity—especially the refractory lining and lid—and streamlining operational procedures to reduce melt and holding times.

True energy savings in an induction furnace come from a holistic approach that treats the furnace not as a single machine, but as a complete thermal system. The fundamental goal is to maximize the useful energy absorbed by the metal while aggressively minimizing every form of energy loss, from heat radiation to inefficient electrical transfer.

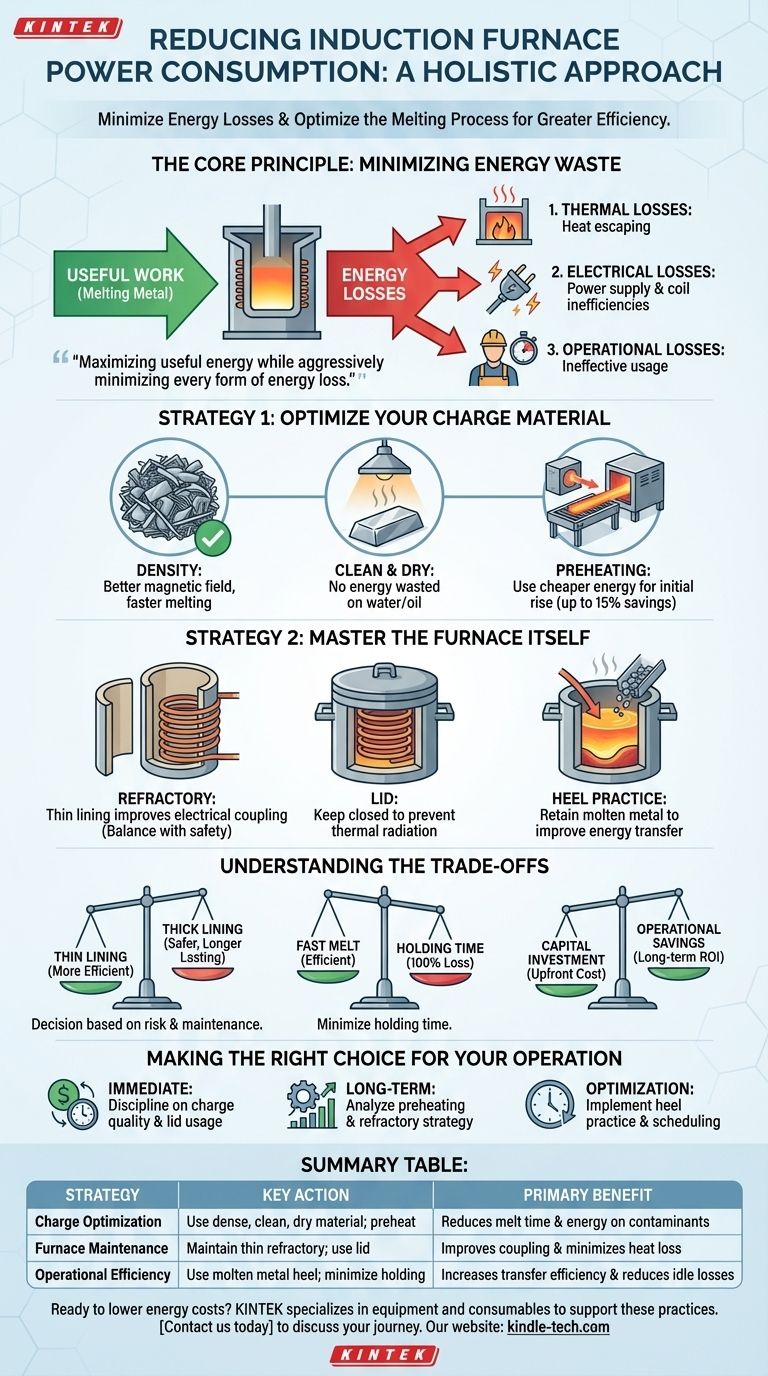

The Core Principle: Minimizing Energy Waste

An induction furnace consumes power for two primary purposes: the useful work of melting metal and the non-productive work of overcoming energy losses. Your electricity bill reflects both.

Understanding Where Power Goes

The energy (measured in kWh) required to melt a ton of metal is a combination of the theoretical energy needed for the phase change and the significant energy wasted to various losses. To reduce consumption, you must attack the losses.

The Three Pillars of Energy Loss

Energy waste in an induction furnace can be categorized into three main areas:

- Thermal Losses: Heat escaping from the furnace.

- Electrical Losses: Inefficiencies in the power supply and coil.

- Operational Losses: Inefficiencies in how the furnace is used.

Strategy 1: Optimize Your Charge Material

The condition of the metal you put into the furnace has a direct and significant impact on energy consumption. This is often the area with the most potential for immediate savings.

The Importance of Charge Density

A densely packed charge provides a better path for the induced magnetic field, leading to more efficient energy transfer and faster melting. Loose, light scrap contains many air gaps, which hinder heating and can increase melt time by 15-20%.

Keep It Clean and Dry

Any water, oil, or cutting fluid on your scrap must be boiled off before the metal can melt. This process consumes a tremendous amount of energy without contributing to the melt. A "dry charge" practice is a foundational step in energy efficiency.

Consider Charge Preheating

Preheating the charge material before it enters the furnace is one of the single most effective methods for reducing electricity consumption. Using a gas-fired preheater can reduce electrical energy usage by 15% or more by offloading the initial temperature rise to a cheaper energy source.

Strategy 2: Master the Furnace Itself

The physical state and operation of the furnace hardware are critical. A well-maintained furnace is an efficient furnace.

The Critical Role of the Refractory Lining

The refractory wall separates the induction coil from the molten metal. A thinner lining means the coil is closer to the charge, which improves electrical coupling and increases melting efficiency. However, this must be balanced against refractory wear and safety.

The Lid Is Not Optional

An open furnace bath loses a massive amount of energy through thermal radiation from the surface of the molten metal. Keeping the lid closed whenever possible is a simple, no-cost habit that directly conserves heat and reduces power draw.

Use a "Heel" Practice

Starting a melt from a completely empty furnace (a "cold start") is inefficient. By retaining a small amount of molten metal—a "heel"—from the previous batch, the new charge is added to an already liquid bath, dramatically improving energy transfer and reducing melt time.

Understanding the Trade-offs

Pursuing efficiency requires making informed decisions, as some strategies involve balancing competing priorities.

Refractory Thickness vs. Efficiency

A thinner lining is more energy-efficient but requires more frequent monitoring and replacement. A thicker, more conservative lining is safer and lasts longer but carries a direct energy penalty on every melt. This is a core operational decision based on your risk tolerance and maintenance schedule.

Melt Rate vs. Holding Time

Melting metal as quickly as possible at the furnace's rated power is generally most efficient. Once the metal is molten, holding it at temperature is 100% energy loss, as no productive work is being done. This highlights the need for tight scheduling between the furnace and the casting line to minimize holding.

Capital Investment vs. Operational Savings

Implementing technologies like charge preheaters, automated charging systems, or modern, high-efficiency power supplies requires upfront capital. This investment must be weighed against the long-term reduction in kilowatt-hours per ton, which can provide a clear return on investment.

Making the Right Choice for Your Operation

Use these points to guide your energy-saving strategy based on your specific capabilities and goals.

- If your primary focus is immediate, low-cost improvements: Enforce strict operational discipline around using clean, dry, dense charges and keeping the furnace lid closed at all times.

- If your primary focus is significant, long-term efficiency: Analyze the return on investment for a charge preheating system and review your refractory lining strategy to see if a slightly thinner wall is feasible.

- If your primary focus is process optimization: Implement a molten metal heel practice and coordinate furnace and casting schedules to eliminate any unnecessary holding time at temperature.

Ultimately, treating every kilowatt-hour as a valuable resource is the key to a more efficient and profitable melting operation.

Summary Table:

| Strategy | Key Action | Primary Benefit |

|---|---|---|

| Charge Optimization | Use dense, clean, dry material; consider preheating | Reduces melt time and energy wasted on contaminants |

| Furnace Maintenance | Maintain thin refractory lining; always use lid | Improves electrical coupling and minimizes heat loss |

| Operational Efficiency | Use a molten metal heel; minimize holding time | Increases energy transfer efficiency and reduces idle losses |

Ready to significantly lower your energy costs and enhance your melting efficiency? The strategies outlined are just the beginning. KINTEK specializes in lab equipment and consumables, serving the precise needs of laboratories and metal melting operations. Our experts can help you select the right equipment and consumables to implement these energy-saving practices effectively. Contact us today to discuss how we can support your journey towards a more efficient and profitable operation.

Visual Guide

Related Products

- Lab-Scale Vacuum Induction Melting Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the difference between induction melting and vacuum induction melting? Choosing the Right Process for Purity

- What is the vacuum induction method? Master High-Purity Metal Melting for Advanced Alloys

- What types of metals are typically processed in a vacuum induction melting furnace? High-Purity Alloys for Critical Applications

- How does induction work in a vacuum? Achieve Ultra-Pure Metal Melting with VIM

- What principle is used to generate heat in a vacuum induction melting furnace? Achieve Clean, Efficient Metal Melting