Preventing mechanical damage to a PTFE electrode stand requires a disciplined approach that encompasses careful handling, correct operational procedures, and proper maintenance. The primary goal is to avoid any physical impact or scratching, especially on the fragile glass cell, and to prevent deformation of sensitive components like the platinum wire electrode.

The electrode stand is not a single-piece tool but a system of diverse materials, each with unique vulnerabilities. Protecting it requires a lifecycle approach that considers how you set it up, use it, clean it, and store it to ensure long-term reliability and experimental integrity.

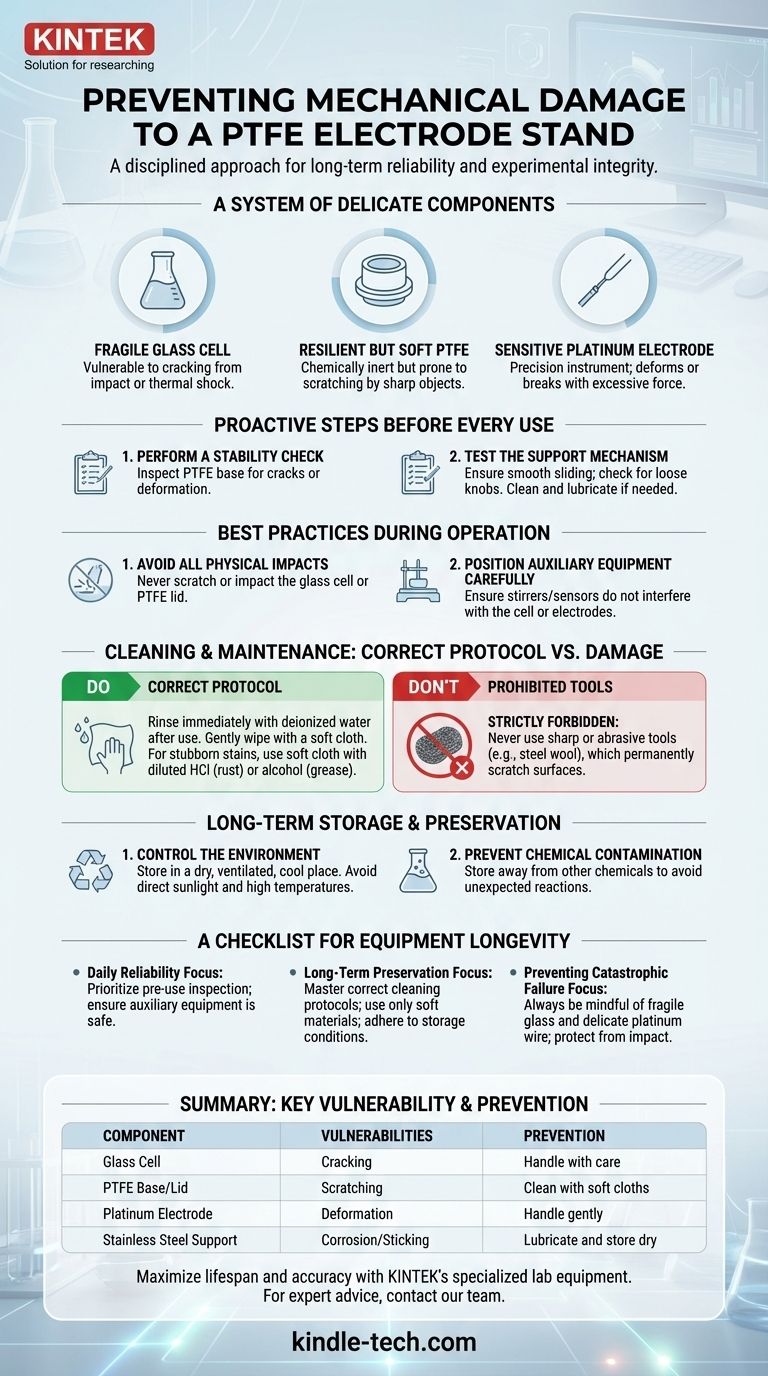

A System of Delicate Components

Understanding the materials is the first step in preventing damage. The stand is an assembly of a PTFE base and lid, a stainless steel support, and a high borosilicate glass cell. Each part demands specific care.

The Fragile Glass Cell

The high borosilicate glass cell is the most vulnerable component. It is highly susceptible to cracking or shattering from physical impacts or sudden, extreme temperature changes.

The Resilient but Soft PTFE

PTFE (polytetrafluoroethylene) is chemically inert but mechanically soft. While it resists corrosion, its surface can be easily scratched or gouged by sharp or hard objects, compromising its non-stick properties and creating sites for contamination.

The Sensitive Platinum Electrode

The platinum wire electrode is a precision instrument. Applying excessive external force during handling, installation, or cleaning can easily cause the delicate wire to deform or break, rendering it useless.

Proactive Steps Before Every Use

A brief inspection before you begin can prevent operational failures and damage. Treat it as a mandatory pre-flight check for your experiment.

Perform a Stability Check

Inspect the PTFE base to ensure it is stable and free from any cracks or deformation. A compromised base can lead to instability and accidents during use.

Test the Support Mechanism

Verify that the lifting support slides smoothly along the stainless steel rod. Check that all adjustment knobs are secure and not loose. If the mechanism feels stuck, clean away any impurities before applying a small amount of lubricant.

Best Practices During Operation

Damage most often occurs during active use. Adhering to careful operational procedures is not optional.

Avoid All Physical Impacts

Handle the entire assembly with care. Never scratch or impact the electrolytic cell with hard objects, as this can easily damage the PTFE lid or, more critically, the glass cell body.

Position Auxiliary Equipment Carefully

When mounting stirrers or temperature sensors, ensure they are positioned so they cannot interfere with or strike the cell or electrodes. A spinning stir paddle making contact with an electrode or the glass wall is a common source of catastrophic failure.

Understanding the Trade-offs: Cleaning vs. Damage

Improper cleaning is a primary cause of gradual, cumulative damage. The goal is to remove contaminants without harming the component surfaces.

The Correct Cleaning Protocol

After use, immediately rinse all fixtures and clamps with deionized water to remove residual electrolyte. For most cleaning tasks, gently wiping the surfaces with a soft cloth and deionized water is sufficient.

Prohibited Tools and Methods

It is strictly forbidden to use sharp or abrasive tools like steel wool for cleaning. These will permanently scratch and damage the surfaces of both the PTFE and metal components.

Addressing Stubborn Contaminants

For stubborn stains, use a soft cloth dampened with a suitable solvent. Dilute hydrochloric acid can be used for metal rust, while alcohol is effective for removing grease. Always wipe gently.

Long-Term Storage and Preservation

How you store the electrode stand is just as important as how you use it. Proper storage protects it from environmental degradation.

Control the Environment

Store the stand in a dry, ventilated, and cool place. Keep it away from direct sunlight and high-temperature environments which can degrade materials over time.

Prevent Chemical Contamination

Ensure the stand is stored away from other chemicals. Accidental contact or vapors can cause unexpected chemical reactions, leading to corrosion or damage.

A Checklist for Equipment Longevity

Your approach to handling the electrode stand directly impacts its lifespan and the quality of your results. Use these points to guide your actions.

- If your primary focus is daily reliability: Prioritize the pre-use inspection of the base and support mechanism, and ensure all auxiliary equipment is positioned safely.

- If your primary focus is long-term preservation: Master the correct cleaning protocols, use only soft materials, and adhere to proper environmental storage conditions.

- If your primary focus is preventing catastrophic failure: Always be mindful of the fragile glass cell and the delicate platinum wire, protecting them from any impact or excessive force.

Adopting these disciplined habits transforms equipment care from a chore into a core part of reliable scientific practice.

Summary Table:

| Component | Key Vulnerability | Prevention Tip |

|---|---|---|

| Glass Cell | Cracking from impact or thermal shock | Handle with care; avoid sudden temperature changes |

| PTFE Base/Lid | Scratching or gouging | Clean with soft cloths; avoid abrasive tools |

| Platinum Electrode | Deformation or breakage from force | Handle gently during installation and cleaning |

| Stainless Steel Support | Corrosion or sticking | Lubricate moving parts; store in dry conditions |

Maximize the lifespan and accuracy of your lab equipment with KINTEK. Our specialized lab equipment and consumables are designed for durability and precision, ensuring your experiments run smoothly. For expert advice on maintaining your PTFE electrode stands or to explore our range of reliable lab solutions, contact our team today and let us support your laboratory's success.

Visual Guide

Related Products

- PTFE Electrolytic Cell Electrochemical Cell Corrosion-Resistant Sealed and Non-Sealed

- Electrolytic Electrochemical Cell for Coating Evaluation

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- H-Type Double-Layer Optical Electrolytic Electrochemical Cell with Water Bath

- Electrolytic Electrochemical Cell with Five-Port

People Also Ask

- What is the precaution regarding temperature when using an all-PTFE electrolytic cell? Essential Thermal Safety Tips

- What materials are used for the body of a super-sealed electrolytic cell and what are their properties? Select the Right Material for Your Experiment

- How should an all-PTFE electrolytic cell be handled to prevent mechanical damage? Protect Your Investment and Data Integrity

- What are the typical volumes for an all-PTFE electrolytic cell? Choose the Right Size for Your Experiment

- What is the proper cleaning method for an all-PTFE electrolytic cell? Essential Tips for Surface Integrity