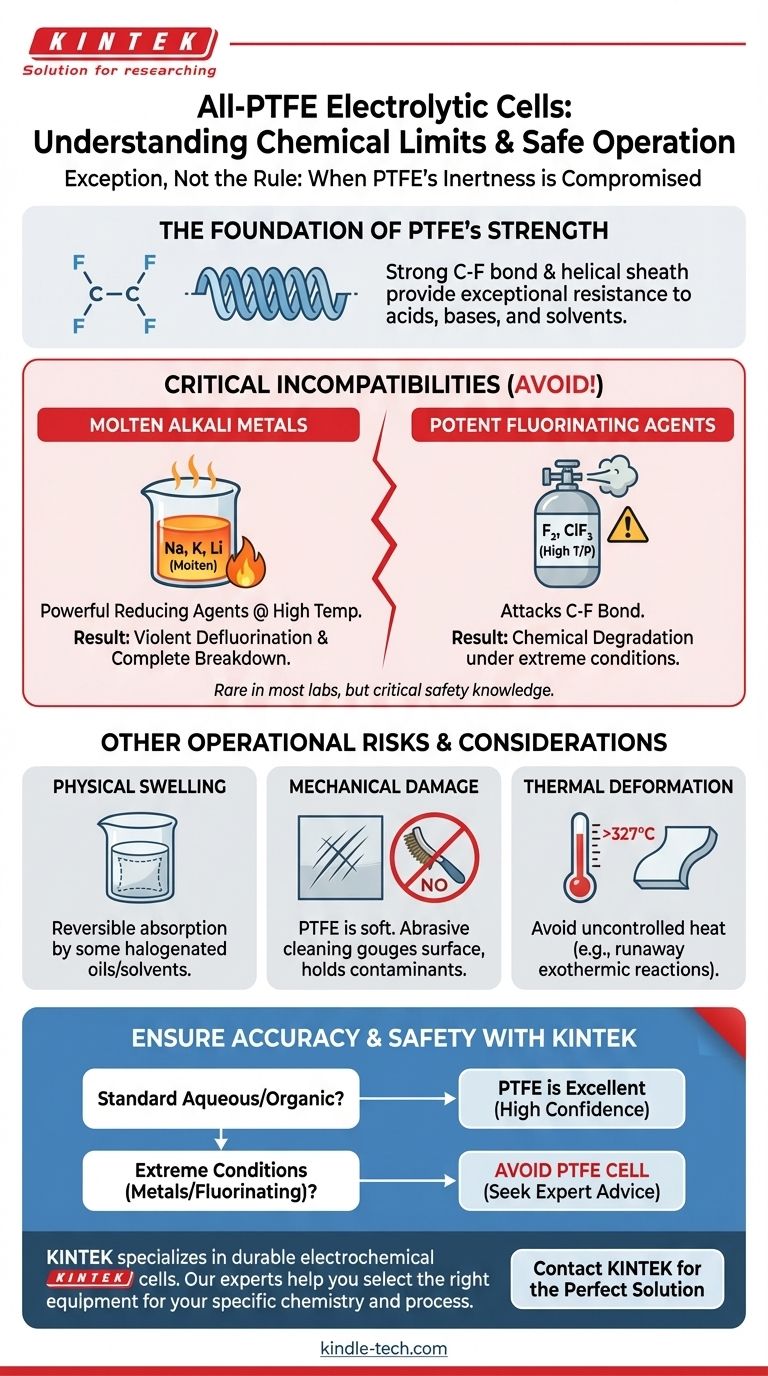

Yes, while PTFE is one of the most chemically inert polymers available, a few specific substances under extreme conditions can cause degradation. For an all-PTFE electrolytic cell, you must avoid contact with molten alkali metals like sodium or potassium, as well as certain potent fluorinating agents at high temperatures. These conditions are rare in most electrochemical work but are critical to be aware of for specialized applications.

PTFE's reputation for being nearly indestructible is well-earned, but its limits are defined by chemistry's most aggressive elements. The primary risk is not from common acids or bases, but from powerful reducing agents (molten alkali metals) or fluorinating agents that can break the strong carbon-fluorine bonds that give PTFE its stability.

The Foundation of PTFE's Resistance

The Carbon-Fluorine Bond

Polytetrafluoroethylene (PTFE) derives its exceptional chemical resistance from the strength and stability of the carbon-fluorine (C-F) bond. This is one of the strongest single bonds in organic chemistry.

The fluorine atoms also create a tight, uniform helical sheath around the carbon backbone, effectively protecting it from chemical attack.

General Inertness

Because of this structure, PTFE is highly resistant to a vast range of substances, including concentrated acids (like sulfuric and nitric acid), strong bases (like sodium hydroxide), all common organic solvents, and powerful oxidizing agents. It is also hydrophobic and non-stick, which helps prevent fouling.

Critical Chemical Incompatibilities

While its resistance is broad, it is not absolute. The following substances and conditions can compromise the integrity of PTFE.

Molten Alkali Metals

This is the most cited incompatibility. Molten alkali metals, such as sodium (Na), potassium (K), and lithium (Li), are extremely powerful reducing agents.

At elevated temperatures (i.e., in their molten state), they have enough energy to strip fluorine atoms directly from the PTFE polymer chain. This causes a violent, often incendiary, defluorination reaction that completely breaks down the material.

Potent Fluorinating Agents

It is logical that substances capable of reacting with the C-F bond itself would pose a threat. Highly reactive fluorinating agents can attack PTFE, especially at elevated temperatures and pressures.

Examples include elemental fluorine (F₂) gas and aggressive interhalogen compounds like chlorine trifluoride (ClF₃). These are highly specialized and hazardous chemicals not found in typical labs.

A Note on Physical Swelling

Some highly halogenated oils and solvents, particularly at temperatures approaching PTFE's service limit, can cause minor physical swelling. This is not a chemical reaction or degradation but a physical absorption process. While it may cause slight dimensional changes, the effect is often reversible upon removal of the solvent and cooling.

Understanding the Trade-offs and Operational Hazards

Beyond direct chemical incompatibility, improper handling can also damage a PTFE cell.

Mechanical Damage is a Real Risk

Although chemically tough, PTFE is a mechanically soft material. Using metal brushes, sharp tools, or abrasive powders for cleaning will scratch and gouge the surface.

These scratches compromise the smooth, non-stick surface, creating sites where contaminants can adhere and potentially leading to cross-contamination between experiments.

Thermal Deformation

PTFE has a relatively low melting point for a high-performance polymer (around 327°C / 621°F). While stable for most electrochemical applications, you must avoid uncontrolled heat sources.

A runaway exothermic reaction, such as improperly mixing a concentrated acid and base inside the cell, can generate enough heat to soften or deform the PTFE body. This is a general safety hazard, not a specific PTFE chemical failure.

Making the Right Choice for Your Goal

Your awareness of these limitations is key to ensuring the longevity of your equipment and the accuracy of your results.

- If your primary focus is aqueous or organic electrochemistry: You can proceed with high confidence, as PTFE is inert to virtually all common acids, bases, salts, and solvents used in these fields.

- If you are working with high-temperature elemental metals: You must avoid using a PTFE cell with alkali metals, as this will result in rapid and hazardous destruction of the equipment.

- If your goal is long-term equipment care: Always use soft, non-abrasive tools for cleaning and adhere to standard lab safety protocols to prevent dangerous exothermic reactions.

Understanding the specific, extreme limits of your materials is the mark of a careful and effective researcher.

Summary Table:

| Substance to Avoid | Conditions | Potential Effect on PTFE |

|---|---|---|

| Molten Alkali Metals (Na, K, Li) | Elevated Temperatures | Violent defluorination, complete breakdown |

| Elemental Fluorine (F₂) | High Temperature/Pressure | Chemical attack, degradation |

| Chlorine Trifluoride (ClF₃) | High Temperature/Pressure | Chemical attack, degradation |

Ensure Your Lab's Safety and Accuracy with the Right Equipment

Navigating the chemical resistance of materials like PTFE is crucial for successful and safe experiments. While PTFE is exceptionally inert, knowing its specific limits protects your research and your lab.

KINTEK specializes in high-quality lab equipment and consumables, including electrochemical cells designed for durability and performance. Our expertise helps you select the right tools for your specific application, ensuring compatibility with your chemicals and processes.

Let our experts help you make the right choice. Whether you need a standard PTFE cell or guidance on a specialized application, we provide the support and equipment to keep your lab running smoothly and safely.

Contact KINTEK today to discuss your laboratory needs and find the perfect solution.

Visual Guide

Related Products

- Electrolytic Electrochemical Cell with Five-Port

- PTFE Electrolytic Cell Electrochemical Cell Corrosion-Resistant Sealed and Non-Sealed

- Double Layer Five-Port Water Bath Electrolytic Electrochemical Cell

- Electrolytic Electrochemical Cell for Coating Evaluation

- Double-Layer Water Bath Electrolytic Electrochemical Cell

People Also Ask

- What are the proper storage procedures for the multifunctional electrolytic cell? Protect Your Investment and Ensure Data Accuracy

- How can contamination be avoided during experiments with the five-port water bath electrolytic cell? Master the 3-Pillar Protocol

- How should the five-port water bath electrolytic cell be cleaned for maintenance? A Step-by-Step Guide to Reliable Results

- What are the standard components of the five-port water bath electrolytic cell? Master the Precision Instrument for Electrochemical Analysis

- What general precaution should be taken when handling the electrolytic cell? Ensure Safe and Accurate Lab Results