To choose the right filter press, you must match the machine's technology to the specific characteristics of your slurry and your desired operational outcomes. The selection process is driven by four key factors: the nature of your slurry (solids type, concentration), the required output (cake dryness and filtrate clarity), the necessary processing scale (volume per day), and the level of automation you require.

The single most critical takeaway is this: do not select a filter press from a catalog. The correct choice is determined by conducting a pilot test on your actual slurry. This test provides the essential data needed to specify a machine that will perform effectively in your real-world environment.

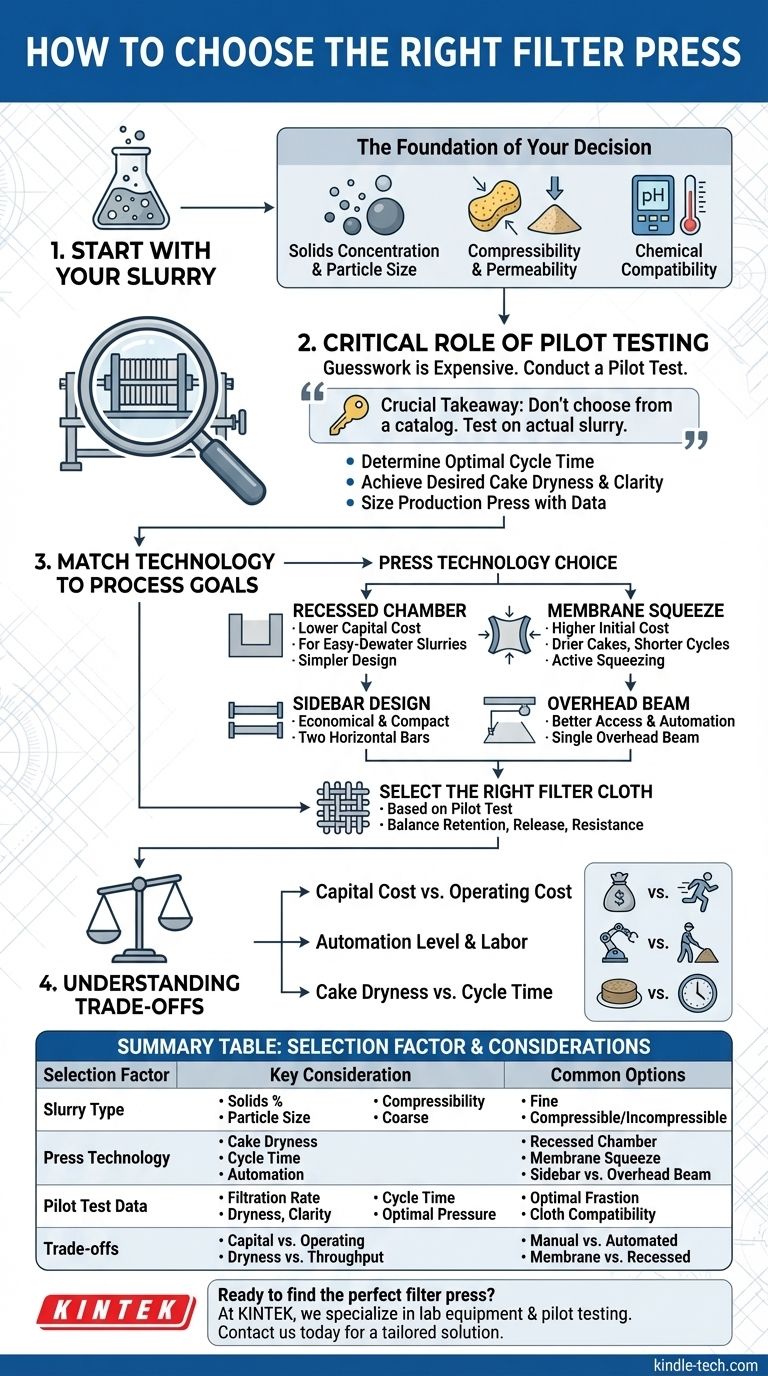

Start with Your Slurry: The Foundation of Your Decision

The filter press is simply a tool. The material it must process—the slurry—dictates the entire design. A thorough understanding of your slurry is the non-negotiable first step.

Solids Concentration and Particle Size

The percentage of solids and the size of the particles in your liquid stream are primary factors. Slurries with very fine particles may require a tighter filter cloth weave and longer cycle times, while coarse, crystalline solids dewater much more easily.

Compressibility and Permeability

This describes how your solids behave under pressure. Compressible solids (like biological sludges) compact and can block the filter media, a phenomenon known as "blinding." Incompressible solids (like sand) maintain void spaces, allowing liquid to pass through more freely even at high pressures.

Chemical Compatibility

The chemical makeup, pH, and temperature of your slurry will determine the required materials for the press. The filter plates (e.g., polypropylene, cast iron), filter cloths (e.g., polypropylene, polyester, nylon), and gaskets must be resistant to chemical attack to ensure a long operational life.

The Critical Role of Pilot Testing

Guesswork is the most expensive way to select industrial equipment. A pilot test is a small-scale trial that uses your slurry to simulate the full-scale filtration process, replacing assumptions with hard data.

What Is a Pilot Test?

A vendor or testing lab will use a small, representative sample of your slurry (typically 5-50 gallons) and run it through a laboratory-scale filter press. The test methodically fills the press, monitors pressure and flow, and evaluates the resulting cake and filtrate.

Key Data from the Test

The test provides the definitive data for your project. You will learn the optimal cycle time, the achievable final cake dryness, the filtrate clarity, and the cake release characteristics (how easily the cake falls off the cloth). The test also determines if a membrane squeeze or cake wash step is beneficial.

Sizing the Production Press

Data from the pilot test, specifically the filtration rate (e.g., gallons per hour per square foot of filter area), is the primary input for sizing the full-scale press. This ensures the machine you buy will meet your required production throughput.

Matching Press Technology to Your Process Goals

With data from your slurry analysis and pilot test, you can now confidently select the right machine configuration.

Recessed Chamber vs. Membrane Squeeze Plates

This is a fundamental choice. A recessed chamber press is simpler and has a lower capital cost. It relies solely on the feed pump's pressure to dewater the solids. It is ideal for easily dewatered slurries or when maximum cake dryness is not critical.

A membrane squeeze press contains flexible diaphragms behind the filter cloth. After the initial feed cycle, these membranes are inflated with water or air, physically squeezing the filter cake to remove additional liquid. This results in significantly drier cakes and shorter cycle times but at a higher initial cost.

Overhead Beam vs. Sidebar Design

This refers to the frame construction. A sidebar press has two horizontal bars on the sides that support the plate stack. They are generally more economical and compact.

An overhead beam press suspends the plates from a single large beam above. This design allows for better access for cleaning and maintenance and is superior for automated systems, such as automatic plate shifters and cloth washers.

Selecting the Right Filter Cloth

The filter cloth is the heart of the press. Its selection is determined by the pilot test. The material is chosen for chemical and temperature compatibility, while the weave pattern is chosen to balance particle retention (filtrate clarity) with resistance to blinding and good cake release.

Understanding the Trade-offs

Every filter press selection involves balancing competing priorities. Being aware of these trade-offs is key to making a sound investment.

Capital Cost vs. Operating Cost

A simple, manual recessed chamber press has the lowest capital cost. However, it may result in higher operating costs due to wetter cake (higher disposal fees) and more intensive labor.

A fully automated membrane squeeze press has a very high capital cost but can dramatically reduce labor and cake disposal costs over its lifetime, often providing a clear return on investment.

Automation Level and Labor

The level of automation directly impacts your staffing needs. A manual press requires an operator to physically open the press, move each plate, and ensure the cake is discharged. A fully automated press can perform an entire cycle, including cake discharge and cloth washing, without operator intervention, ensuring consistency and minimizing labor.

Cake Dryness vs. Cycle Time

Achieving the highest possible cake dryness often requires more time—either a longer feed cycle or the additional time for a membrane squeeze and air blow. You must decide if the value of a drier cake outweighs a potential reduction in overall throughput. The pilot test will quantify this trade-off for you.

Making the Right Choice for Your Goal

Use your test data to guide your final decision based on your primary objective.

- If your primary focus is maximum cake dryness: Choose a membrane squeeze press with air blow-down capability to minimize disposal weight and costs.

- If your primary focus is highest throughput: Choose a larger, fully automated recessed chamber or membrane press to minimize time between cycles.

- If your primary focus is handling difficult-to-filter slurries: Invest heavily in pilot testing, potentially including chemical pre-treatment (flocculants), and select a membrane press to actively squeeze out moisture.

- If your primary focus is the lowest initial investment: Choose a manual, sidebar-style recessed chamber press, but be prepared for higher long-term labor and disposal costs.

By grounding your decision in empirical data from your own process, you move from guessing to making a sound engineering investment.

Summary Table:

| Selection Factor | Key Consideration | Common Options |

|---|---|---|

| Slurry Type | Solids concentration, particle size, compressibility | Fine particles, coarse solids, compressible/incompressible |

| Press Technology | Cake dryness, cycle time, automation level | Recessed chamber, membrane squeeze, sidebar vs. overhead beam |

| Pilot Test Data | Filtration rate, cake dryness, filtrate clarity | Cycle time, optimal pressure, cloth compatibility |

| Trade-offs | Capital cost vs. operating cost, dryness vs. throughput | Manual vs. automated, membrane vs. recessed |

Ready to find the perfect filter press for your specific slurry? Don't leave your filtration efficiency to chance.

At KINTEK, we specialize in lab equipment and consumables, serving diverse laboratory needs. Our experts can help you pilot test your slurry and recommend the ideal filter press configuration—whether you prioritize maximum cake dryness, high throughput, or cost-effectiveness.

Contact us today to discuss your application and get a tailored solution that delivers reliable performance and long-term value.

Visual Guide

Related Products

- Hydraulic Diaphragm Lab Filter Press for Laboratory Filtration

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- What is the number one cause of failure in hydraulic systems? The Silent Killer of Your Equipment

- What are the disadvantages of hydraulic machines? Key Trade-offs in Power and Performance

- What are the most common causes of hydraulic system failure? Prevent Downtime and Costly Repairs

- What are the failures in a hydraulic system? Prevent Costly Downtime with Expert Diagnosis

- What are the preventive maintenance of hydraulic systems? Extend Equipment Life and Maximize Uptime