Properly handling a muffle furnace involves a methodical sequence of preparation, operation, and cooldown steps designed to ensure safety and accuracy. The core process includes carefully placing your sample, setting the required temperature on the control panel, monitoring the heating cycle, and using appropriate tools like crucible tongs to handle materials gently and safely.

The key to successfully using a muffle furnace is not complex operation, but rather a disciplined focus on safety and precision. Following correct procedure protects the sensitive internal components from damage, ensures the integrity of your sample, and prevents serious personal injury from extreme heat.

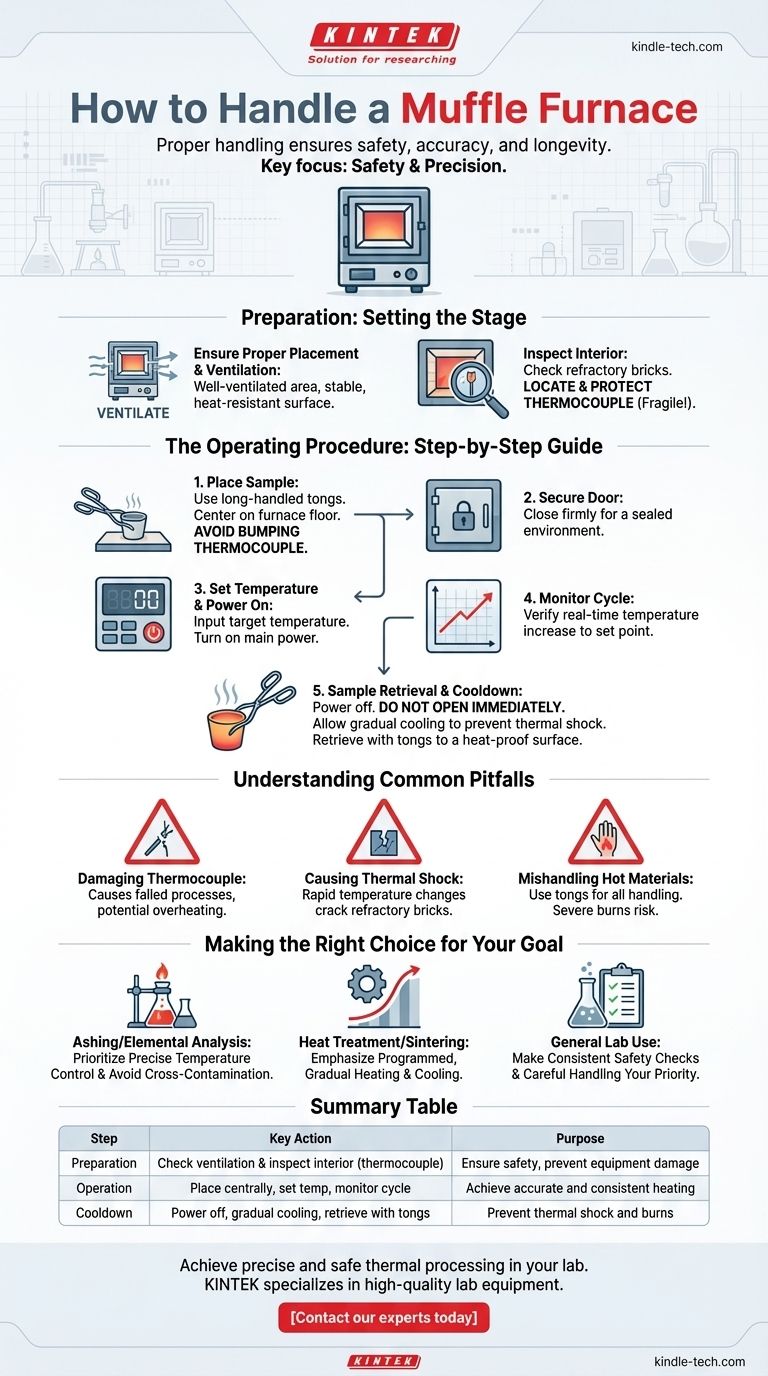

Preparation: Setting the Stage for Success

Before you even turn the power on, a few preparatory steps are critical for a safe and effective heating cycle.

Ensure Proper Placement and Ventilation

A muffle furnace generates extreme heat and can release fumes from the materials being processed. Ensure the unit is in a well-ventilated area to prevent the buildup of potentially harmful gases.

The furnace should be on a stable, heat-resistant surface with adequate clearance on all sides to allow for heat dissipation.

Inspect the Furnace Interior

Visually inspect the internal chamber before each use. The chamber is lined with refractory bricks or ceramic fiber insulation that can be damaged by careless handling.

Most importantly, locate the thermocouple. This is a thin, temperature-sensing probe, usually located at the back of the chamber. It is extremely fragile and critical for accurate temperature regulation.

The Operating Procedure: A Step-by-Step Guide

Once preparations are complete, you can proceed with the heating cycle.

Step 1: Place Your Sample

Using long-handled crucible tongs, place your crucible or sample container carefully inside the furnace.

Position the item in the center of the furnace floor. Never let your sample or the tongs touch or bump the thermocouple, as this is a primary cause of equipment failure.

Step 2: Secure the Furnace Door

Close the furnace door firmly to ensure it is sealed. A proper seal is essential for maintaining a stable internal temperature and preventing significant heat loss.

Step 3: Set the Temperature and Power On

Set your desired target temperature using the furnace's control panel. Once the temperature is set, turn on the main power switch.

The control panel display will typically show key information like the set temperature, the real-time internal temperature, and power indicators.

Step 4: Monitor the Heating Cycle

As the furnace operates, the real-time temperature display should steadily increase until it reaches your set point. This confirms that the heating elements and control system are working correctly.

The furnace will then regulate its power output to maintain the target temperature for the duration of your process.

Step 5: Sample Retrieval and Cooldown

Once your process is complete, turn off the furnace power.

Do not open the door immediately. Allow the furnace to cool down for a significant period. Opening the door while the interior is at a very high temperature can cause thermal shock, damaging both your sample and the furnace's refractory lining.

Once the temperature has dropped to a safe level, use crucible tongs to carefully remove your hot sample and place it on a heat-proof surface to cool completely.

Understanding the Common Pitfalls

Avoiding common mistakes is crucial for the longevity of the furnace and the safety of the operator.

Damaging the Thermocouple

Accidentally bumping or breaking the thermocouple is the most common and costly user error. Without accurate temperature feedback from the thermocouple, the furnace cannot regulate heat properly, leading to failed processes and potential overheating.

Causing Thermal Shock

Rapid temperature changes are the enemy of a muffle furnace. Slamming the door open at high temperatures or placing a very cold, large item into a pre-heated furnace can crack the delicate refractory bricks that line the chamber.

Mishandling Hot Materials

Crucible tongs must be used for all item placement and retrieval. Even after the furnace has been off for some time, the samples and the furnace interior can remain hot enough to cause severe burns. Gentle and steady handling also prevents damage to the furnace floor.

Making the Right Choice for Your Goal

Your specific application will determine which operational details to prioritize.

- If your primary focus is ashing or elemental analysis: Prioritize precise temperature control and avoid any cross-contamination between samples.

- If your primary focus is heat treatment or sintering: Emphasize programmed, gradual heating and cooling cycles to prevent thermal shock from cracking your material.

- If your primary focus is general lab use: Make consistent safety checks and careful handling of the thermocouple your highest priorities to ensure equipment longevity.

By treating the muffle furnace with methodical care, you ensure accurate results, safe operation, and a long service life for the equipment.

Summary Table:

| Step | Key Action | Purpose |

|---|---|---|

| Preparation | Check ventilation & inspect interior (thermocouple) | Ensure safety and prevent equipment damage |

| Operation | Place sample centrally, set temperature, monitor cycle | Achieve accurate and consistent heating |

| Cooldown | Power off, allow gradual cooling, retrieve with tongs | Prevent thermal shock and burns |

Achieve precise and safe thermal processing in your lab. Proper handling is key to maximizing your muffle furnace's performance and lifespan. KINTEK specializes in high-quality lab equipment and consumables, serving all your laboratory needs. Contact our experts today to find the perfect muffle furnace and accessories for your specific application, ensuring reliable results every time.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- Which furnace is used for sintering? A Guide to Choosing the Right System for Your Application

- What are the methods of ashing food? Choose the Right Technique for Accurate Mineral Analysis

- What is the ashing method in analytical chemistry? A Key Process for Precise Sample Analysis

- What is the necessity of a high-temperature calcination process in the synthesis of CoWO4 nanomaterials? Unlock Purity

- Why is a muffle furnace used for CaFe2O4 coating heat resistance? Achieve Precise Thermal Testing Results

- How does a muffle furnace with a PID controller impact doped zinc oxide nanoparticles? Precise Synthesis Control

- What is the difference between muffle furnace and hot oven? A Guide to Choosing the Right Thermal Tool

- What do you know about heat treatment furnace? Master Material Transformation with Precision Control