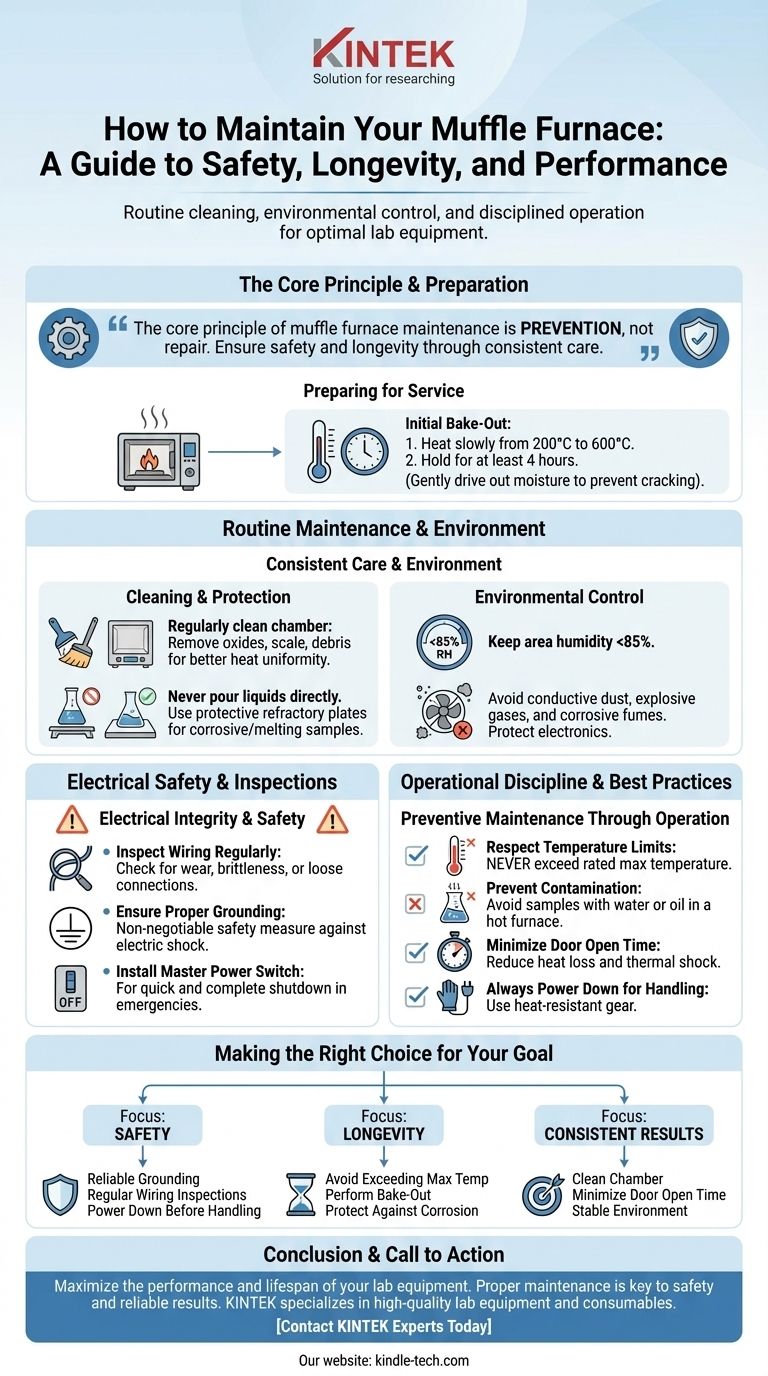

To properly maintain a muffle furnace, you must integrate a disciplined approach that includes routine cleaning, environmental control, regular electrical inspections, and strict adherence to correct operating procedures. This proactive care prevents damage to the heating elements and refractory lining, ensuring both safety and a long operational life for the equipment.

The core principle of muffle furnace maintenance is prevention, not repair. Longevity and safety are achieved through a consistent routine of keeping the chamber clean, controlling the environment, and operating the unit within its specified limits.

Preparing the Furnace for Service

Before putting a furnace into regular use, especially for the first time or after a long period of inactivity, a critical conditioning step is required.

The Initial Bake-Out

A furnace that has been idle can absorb moisture into its refractory insulation. Powering it directly to a high temperature can cause this moisture to turn to steam, potentially cracking the insulation.

To prevent this, perform a bake-out. Heat the furnace slowly from 200℃ to 600℃ and hold it for at least four hours to gently drive out any accumulated moisture.

Routine Maintenance and Environmental Control

Consistent care is essential for the furnace's reliability and longevity. This involves both cleaning the chamber and managing the external environment.

Keeping the Chamber Clean

The furnace chamber must be kept clean to ensure efficient heating and prevent cross-contamination of samples.

Regularly shut down the furnace, allow it to cool completely, and remove any oxides, scale, or debris from the chamber floor and walls. A clean chamber provides better heat uniformity.

Protecting Against Corrosion

Certain materials can aggressively attack the furnace's refractory lining, leading to premature failure.

Never pour any liquid directly into the furnace. For samples that may melt or release corrosive substances, such as alkaline materials, always place them on a protective refractory plate.

Managing the Operating Environment

The furnace's surroundings have a direct impact on its electronic components and overall safety.

The furnace and its controller must be located in an area with less than 85% relative humidity. The environment should be free from conductive dust, explosive gases, or corrosive fumes that could damage the electronics or create a safety hazard.

Electrical Safety and Inspections

Electrical integrity is paramount for both operator safety and the proper functioning of the furnace.

Inspecting Wiring Regularly

Periodically inspect the wiring for both the furnace and the controller. Look for signs of wear, brittleness from heat, or loose connections and address them immediately.

Ensuring Proper Grounding

Both the furnace and the controller must be reliably grounded. This is a non-negotiable safety measure to protect operators from the risk of severe electric shock in the event of an electrical fault.

Installing a Master Power Switch

For enhanced safety, a dedicated master power switch should be installed on the main power line feeding the furnace. This allows for a quick and complete shutdown of all power to the unit in an emergency.

Operational Discipline as Preventive Maintenance

How you operate the furnace daily is the most significant form of maintenance you can perform. Poor habits are the leading cause of damage.

Respect the Temperature Limits

Never exceed the furnace's rated maximum temperature. Doing so will drastically shorten the life of the heating elements and can cause permanent damage to the furnace structure.

Prevent Contamination

Do not place samples containing water or oil into a hot furnace. The rapid vaporization can damage the sample and the furnace interior.

Minimize Door Open Time

Keep the time the furnace door is open to an absolute minimum. A prolonged open door causes rapid temperature drops, forcing the heating elements to work harder and inducing thermal shock on the refractory lining.

Always Power Down for Handling

To prevent electric shock, always cut off the power supply before loading or removing samples from the furnace. Additionally, wear appropriate heat-resistant gloves and eye protection to prevent severe burns.

Making the Right Choice for Your Goal

Your maintenance focus can be tailored to prioritize specific outcomes, whether it's ensuring operator safety, maximizing the furnace's lifespan, or achieving the most repeatable results.

- If your primary focus is safety: Prioritize reliable grounding, regular wiring inspections, and strict adherence to powering down the unit before handling samples.

- If your primary focus is equipment longevity: Focus on never exceeding the maximum temperature, performing the initial bake-out, and keeping the chamber free from corrosive materials.

- If your primary focus is consistent, repeatable results: Ensure the chamber is always clean, the operating environment is stable, and door open time is minimized to maintain thermal uniformity.

Ultimately, a disciplined and consistent approach to these procedures will ensure your muffle furnace remains a safe, reliable, and effective tool.

Summary Table:

| Maintenance Focus | Key Actions |

|---|---|

| Safety | Regular wiring inspections, reliable grounding, power down before handling. |

| Longevity | Avoid exceeding max temperature, perform bake-out, protect against corrosion. |

| Consistent Results | Keep chamber clean, minimize door open time, stable environment. |

Maximize the performance and lifespan of your lab equipment. Proper maintenance is key to safety and reliable results. KINTEK specializes in high-quality lab equipment and consumables, serving all your laboratory needs. Contact our experts today to ensure your muffle furnace and other instruments operate at their best!

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- Why must a high-temperature furnace be used after diffusion chromizing? Restoring Core Strength and Plasticity

- How do the properties of materials change with the heat treatment? Tailor Hardness, Strength, and Ductility

- What is a ceramic furnace? The Essential Tool for Transforming Clay into Durable Ceramics

- What role does a high-temperature muffle furnace play in Cu-TiO2 thin films? Achieve Precise Phase Transformation

- How to choose a laboratory oven? Master the 5 Technical Pillars for Precise Results

- How do you clean a muffle furnace? A Step-by-Step Guide to Ensure Safety and Longevity

- How do synthesis furnaces influence chemical durability? Control Structural Integrity & Stability in Oxide Ceramics

- What is the ash content of a furnace? The Tool vs. The Measurement Explained