The best way to protect a PVD coating is not to add another layer on top of it. In almost all applications, the Physical Vapor Deposition (PVD) coating is the final, durable, protective layer itself. True protection comes from proper cleaning, routine maintenance, and an understanding of the coating's inherent limitations.

The core principle is simple: You don't coat a PVD finish for protection; you care for it. The PVD layer is designed to be the primary shield for the object, and its longevity depends on proper maintenance, not the application of a secondary product.

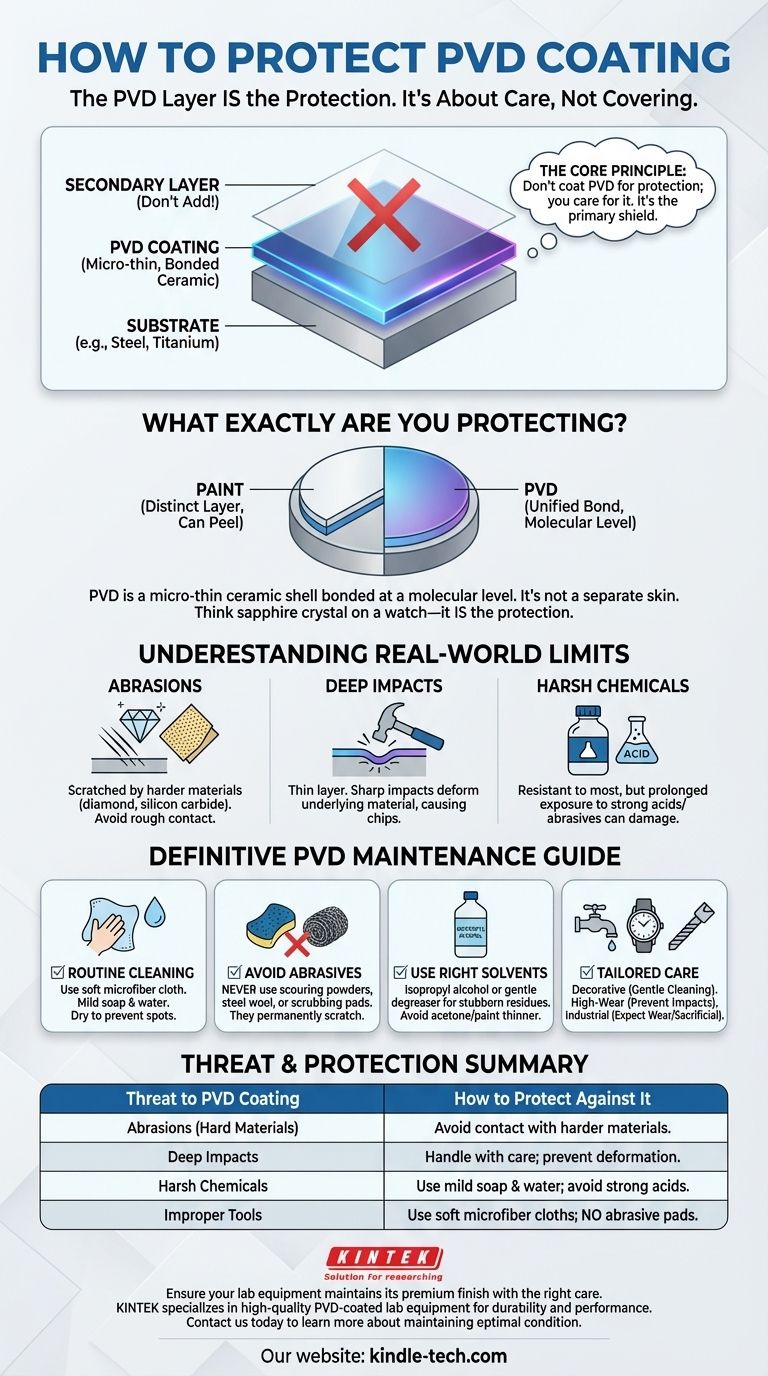

What Exactly Are You Protecting?

The question of "protecting PVD" stems from a common misunderstanding. Unlike paint or powder coating, which are distinct layers sitting on a surface, PVD is a micro-thin ceramic layer that is bonded to the substrate at a molecular level.

The PVD Layer Is the Protection

PVD coatings, such as Titanium Nitride (TiN) or Zirconium Nitride (ZrN), are chosen specifically for their exceptional hardness and resistance to wear. The coating functions as a durable shell, often significantly harder than the steel, titanium, or chrome-plated material underneath it.

Think of it like the sapphire crystal on a high-end watch. You don't put a screen protector on the sapphire; the sapphire is the protection.

A Unified Bond, Not a Separate Coat

Processes like plasma sputtering, mentioned in your references, don't just "spray" material onto a surface. They use high-energy ions to bombard a source material, which then deposits atom by atom onto the substrate, creating a powerful, unified bond.

This is why PVD adheres so well to materials like stainless steel and properly prepared chrome plating. The finish is not a separate skin that can easily peel; it's an integral part of the surface itself.

Understanding the Real-World Limits of PVD

While exceptionally durable, no surface is indestructible. Understanding how a PVD finish can be damaged is the key to preventing it.

Damage from Abrasions

A PVD coating can be scratched by any material that is harder than it is. While resistant to everyday scuffs, contact with materials like diamond, sapphire, or silicon carbide (found in some sandpapers and grinding wheels) will cause scratches.

Damage from Deep Impacts

PVD coatings are very thin, typically only a few microns. A sharp, heavy impact can dent or gouge the softer substrate metal underneath the coating. While the PVD layer might not scratch, it can be compromised if the underlying material is deformed, leading to a chip or flake at the point of impact.

Damage from Harsh Chemicals

PVD is highly resistant to corrosion, sweat, and most household chemicals. However, prolonged exposure to extremely aggressive or abrasive chemical agents (e.g., strong industrial acids, abrasive polishes, or harsh scouring powders) can eventually stain or damage the finish.

The Definitive Guide to PVD Maintenance

Protecting your PVD-coated item is not about adding a product. It's about a simple, consistent maintenance routine.

Routine Cleaning: Softer is Better

For general cleaning, use a soft microfiber cloth with mild soap and water. This is sufficient to remove fingerprints, oils, and dirt without harming the finish. Always dry the item with a clean, soft cloth to prevent water spots.

Avoid Abrasive Cleaners and Tools

Never use abrasive cleaners, scouring powders (like Comet or Ajax), or scrubbing pads and steel wool. These contain hard mineral or metal particles that will permanently scratch and dull the PVD finish.

Use the Right Solvents

For stubborn residues, you can use isopropyl alcohol or a gentle degreaser on a soft cloth. Avoid harsh solvents like acetone or paint thinner unless explicitly approved by the product's manufacturer, as they can sometimes affect the finish.

Making the Right Choice for Your Goal

Your approach to care depends entirely on what the PVD-coated item is and how it is used.

- If your primary focus is decorative fixtures (faucets, hardware): The key is gentle, regular cleaning with a microfiber cloth and mild soap to maintain its luster and prevent mineral buildup.

- If your primary focus is high-wear items (watches, jewelry): Be most mindful of preventing deep scratches and impacts from hard surfaces like concrete, brick, or granite countertops.

- If your primary focus is industrial tools (drill bits, end mills): Recognize that wear is expected and the coating is sacrificial; its purpose is to extend the usable life of the tool, not to remain cosmetically perfect.

Ultimately, a PVD finish is best protected by treating it with the same care you would any high-quality, durable surface.

Summary Table:

| Threat to PVD Coating | How to Protect Against It |

|---|---|

| Abrasions from harder materials | Avoid contact with diamonds, sapphire, or rough surfaces. |

| Deep impacts | Handle with care to prevent substrate deformation. |

| Harsh chemicals | Use mild soap and water; avoid abrasive cleaners. |

| Improper cleaning tools | Use soft microfiber cloths; never use steel wool or scouring pads. |

Ensure your lab equipment maintains its premium finish with the right care. KINTEK specializes in high-quality lab equipment and consumables, including PVD-coated tools designed for durability and performance. Our products are built to withstand rigorous use when maintained correctly.

Contact us today to learn more about our PVD-coated lab equipment and how to keep them in optimal condition for longer-lasting performance.

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

People Also Ask

- How are tools coated with diamond? Achieve Superior Hardness and Low Friction for Your Tools

- What are the three types of coating? A Guide to Architectural, Industrial, and Special Purpose

- How thick is CVD diamond coating? Balancing Durability and Stress for Optimal Performance

- Is diamond coating worth it? Maximize Component Life and Performance

- What are diamond coated films? Enhance Materials with Super-Hard, Transparent Layers