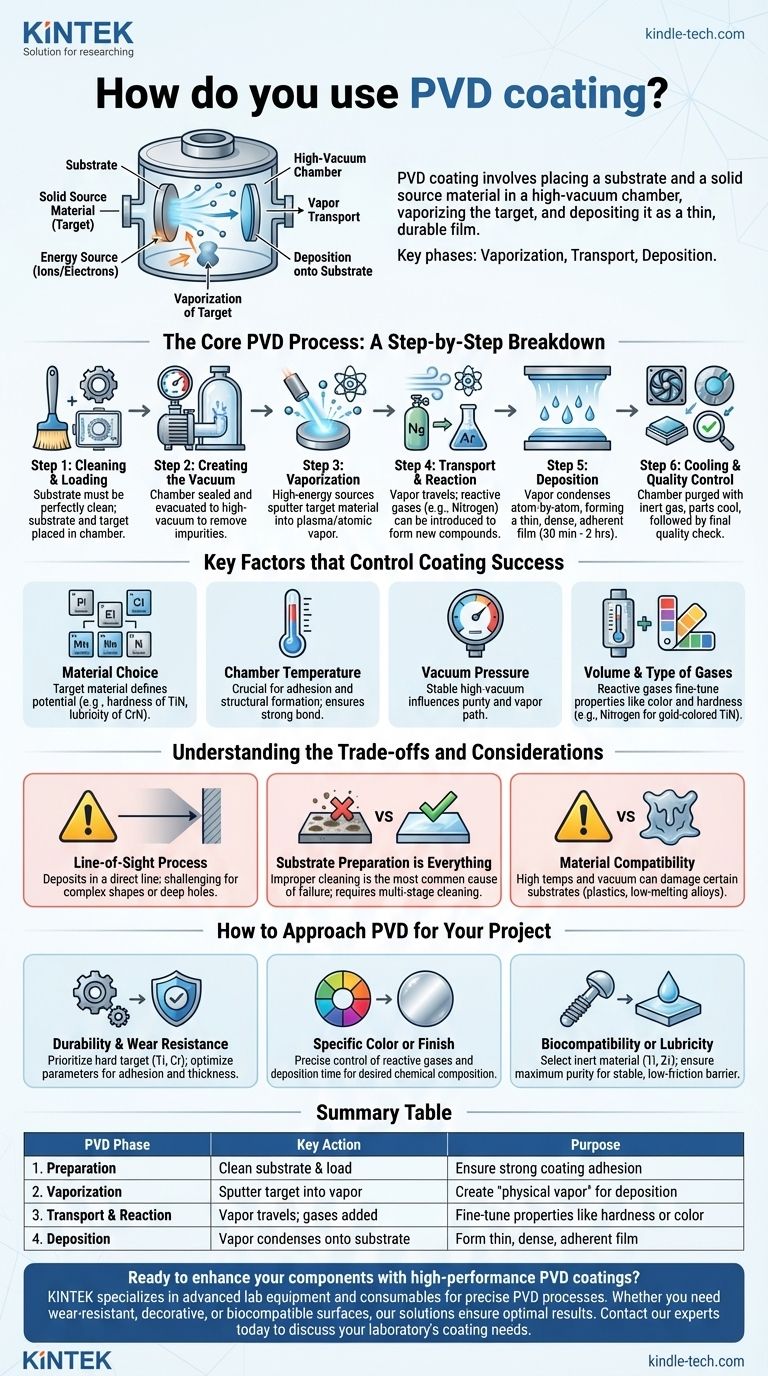

To use Physical Vapor Deposition (PVD) coating, you place a substrate and a solid source material (the target) inside a high-vacuum chamber. The target material is then vaporized using energy like ions or electrons, and this vapor travels through the vacuum to condense onto the substrate, forming a very thin, durable film. The entire process consists of three core phases: vaporization of the target, transport of the vapor, and deposition onto the part being coated.

The PVD process is less about a single "application method" and more about precisely controlling a sophisticated environment. Success depends entirely on manipulating variables like temperature, vacuum pressure, and reactive gases to engineer a coating with specific properties like hardness, color, or friction resistance.

The Core PVD Process: A Step-by-Step Breakdown

The PVD process is highly technical and occurs within a sealed vacuum chamber. While methods can vary, the fundamental stages remain consistent.

Step 1: Cleaning and Loading

Before the process begins, the component to be coated (the substrate) must be perfectly clean. Any surface contaminants will prevent the coating from adhering properly. The substrate and the solid target material are then placed into the vacuum chamber.

Step 2: Creating the Vacuum

The chamber is sealed and evacuated to an extremely low pressure. This high-vacuum environment is critical, as it removes atmospheric gases and impurities that could react with the vaporized material and compromise the coating's integrity.

Step 3: Vaporization

High-energy sources are used to bombard the target material, causing its atoms to be ejected or "sputtered" into a vapor. This is the "Physical Vapor" part of the name. This step transforms the solid source material into a plasma or atomic vapor.

Step 4: Transport and Reaction

The vaporized atoms travel across the vacuum chamber toward the substrate. During this phase, reactive gases (like nitrogen or argon) can be introduced. These gases react with the metal vapor to form new compounds, which is key to determining the final properties of the coating.

Step 5: Deposition

The vaporized material condenses on the surface of the substrate, atom by atom. This forms a thin, dense, and highly-adherent film. The entire process typically takes between 30 minutes and two hours, depending on the part size and desired thickness.

Step 6: Cooling and Quality Control

Once the desired thickness is achieved, the energy source is shut off and the chamber is purged with an inert gas. The newly coated parts are allowed to cool before being removed for a final quality control check to ensure complete and even coverage.

Key Factors that Control Coating Success

Achieving a specific outcome with PVD is not accidental. It is the result of carefully controlling several key variables during the process.

The Choice of Coating Material

The target material fundamentally defines the coating's potential. Materials are chosen for their intrinsic properties, such as the hardness of titanium nitride or the lubricity of chromium nitride.

Chamber Temperature

Temperature control is crucial. It affects the adhesion of the coating to the substrate and the structural formation of the film itself. The correct temperature ensures a strong, durable bond.

Vacuum Pressure

The level of vacuum must be suitable and stable throughout the process. Pressure influences the purity of the coating and the path the vaporized atoms take to reach the substrate.

Volume and Type of Gases

The introduction of reactive gases is how properties like color and hardness are fine-tuned. For example, adding nitrogen to a titanium vapor creates the familiar gold-colored Titanium Nitride (TiN) coating, which is extremely hard.

Understanding the Trade-offs and Considerations

While powerful, PVD is not a universal solution. Understanding its limitations is key to using it effectively.

It's a Line-of-Sight Process

PVD deposits material in a direct line from the source to the substrate. This can make it challenging to coat the inside of complex shapes or deep, narrow holes uniformly without specialized fixtures and part rotation.

Substrate Preparation is Everything

The single most common cause of PVD coating failure is improper surface preparation. The substrate must be surgically clean for the coating to adhere properly. This often requires multi-stage cleaning and pre-treatment processes.

Material Compatibility

Not all materials are suitable for PVD coating. The high temperatures and vacuum environment can damage or alter certain substrates, particularly plastics or low-melting-point alloys.

How to Approach PVD for Your Project

Choosing the right PVD parameters depends entirely on your end goal. The process can be tailored to meet a wide range of performance and aesthetic requirements.

- If your primary focus is durability and wear resistance: Prioritize a hard target material like titanium or chromium and ensure the process parameters are optimized for strong adhesion and sufficient thickness.

- If your primary focus is a specific color or finish: Your success will depend on the precise control of reactive gases and deposition time to achieve the desired chemical composition on the surface.

- If your primary focus is biocompatibility or lubricity: Select an inert material like titanium or zirconium and run a process that ensures maximum purity to create a stable barrier that reduces friction.

By understanding these core principles, you can leverage the PVD process not just as a coating, but as an integral part of your product's design and performance.

Summary Table:

| PVD Phase | Key Action | Purpose |

|---|---|---|

| 1. Preparation | Clean substrate & load into vacuum chamber | Ensure strong coating adhesion |

| 2. Vaporization | Use energy to sputter target material into vapor | Create the "physical vapor" for deposition |

| 3. Transport & Reaction | Vapor travels; reactive gases (e.g., nitrogen) may be added | Fine-tune properties like hardness or color |

| 4. Deposition | Vapor condenses atom-by-onto the substrate | Form a thin, dense, and highly-adherent film |

Ready to enhance your components with high-performance PVD coatings? KINTEK specializes in advanced lab equipment and consumables for precise PVD processes. Whether you need wear-resistant, decorative, or biocompatible surfaces, our solutions ensure optimal results. Contact our experts today to discuss how we can support your laboratory's coating needs.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Vacuum Hot Press Furnace Machine for Lamination and Heating

People Also Ask

- What is the difference between CVD and PECVD? Choose the Right Thin-Film Deposition Method

- What is PECVD silicon deposition? Achieve Low-Temperature, High-Quality Thin Films

- What is the difference between PECVD and CVD? Unlock the Right Thin-Film Deposition Method

- How does plasma enhanced CVD work? Achieve Low-Temperature, High-Quality Thin Film Deposition

- What is plasma enhanced chemical vapor deposition? Achieve Low-Temperature, High-Quality Thin Films