In essence, DC magnetron sputtering is a vacuum-based coating process that uses a powerful electric field to accelerate ions and a clever magnetic field to dramatically increase the efficiency of that process. Positive ions from a gas plasma bombard a source material (the "target"), knocking atoms loose. These atoms then travel and deposit as a thin, highly uniform film onto a component (the "substrate").

The defining feature is not the sputtering itself, but the magnetron. By using a magnetic field to trap electrons near the target, the system creates a dense, self-sustaining plasma that allows for much faster and more controlled deposition at lower pressures than other methods.

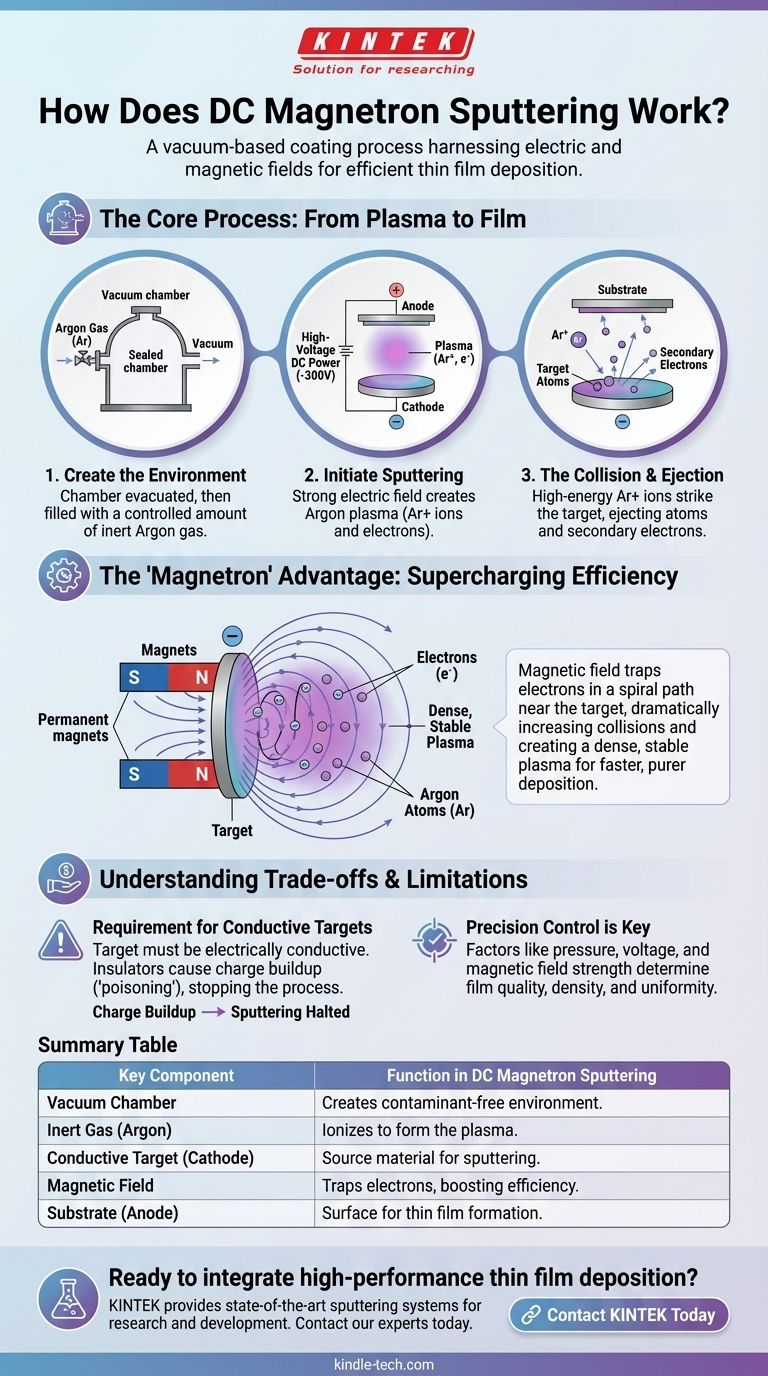

The Core Process: From Plasma to Film

At its heart, magnetron sputtering is a Physical Vapor Deposition (PVD) technique. The goal is to physically move atoms from a source material to a substrate, one atomic layer at a time. The process unfolds in a few key stages.

Creating the Environment

The entire process occurs inside a sealed vacuum chamber. First, the chamber is evacuated to remove air and other contaminants.

Then, a small, precisely controlled amount of an inert gas, typically Argon (Ar), is introduced. This gas is not reactive but will serve as the source of the ions needed for sputtering.

Initiating the Sputtering

A high-voltage DC power supply is activated, applying a strong negative charge (e.g., -300V) to the target material, which acts as the cathode.

The chamber walls and the substrate holder are grounded, acting as the anode. This strong electric field strips electrons from the Argon atoms, creating a plasma of free electrons and positively charged Argon ions (Ar+).

These positively charged Ar+ ions are now strongly attracted to the negatively charged target and accelerate toward it at high speed.

The Collision and Ejection

When the high-energy Ar+ ions strike the target surface, they transfer a significant amount of kinetic energy, much like a cue ball striking a rack of billiard balls.

If the transferred energy is great enough, it can knock atoms loose from the target's surface. This ejection of target atoms is the "sputting" event. Secondary electrons are also ejected, which play a crucial role.

The "Magnetron" Advantage: Supercharging Efficiency

Simple sputtering works, but it is slow and inefficient. The addition of a magnetron assembly, typically a set of permanent magnets placed behind the target, transforms the process.

The Role of the Magnetic Field

The magnets create a magnetic field that is perpendicular to the electric field directly in front of the target's surface.

This magnetic field has a profound effect on the light, negatively charged electrons, but a negligible effect on the heavy, positive Argon ions.

Trapping Electrons for Maximum Impact

As secondary electrons are knocked loose from the target, they are immediately attracted back toward it by the electric field. However, the perpendicular magnetic field forces them into a tight, looping spiral path along the magnetic field lines.

This traps the electrons near the target surface, dramatically increasing their path length. Instead of escaping to the anode, they spiral for a long time, colliding with and ionizing many more Argon atoms along the way.

The Result: A Dense, Stable Plasma

This electron-trapping mechanism creates a very dense and stable plasma concentrated directly in front of the target.

More plasma means more Ar+ ions are created, which leads to a much higher rate of ion bombardment on the target. This directly translates to a higher sputtering rate and faster film deposition. It also allows the process to be sustained at much lower gas pressures, leading to higher-purity films.

Understanding the Trade-offs and Limitations

While powerful, DC magnetron sputtering is not a universal solution. Its operating principle creates a critical constraint.

The Requirement for Conductive Targets

The process relies on a DC voltage, which requires a constant flow of electric current. This means the target material must be electrically conductive.

If you attempt to sputter an insulating (dielectric) material like a ceramic, the positive charge from the bombarding Ar+ ions would quickly accumulate on the target's surface. This charge buildup, known as "target poisoning," would neutralize the negative voltage and halt the sputtering process entirely.

The Need for Precise Control

The quality of the final film—its thickness, density, and uniformity—is highly dependent on process parameters.

Factors like gas pressure, the voltage applied to the target, and the strength of the magnetic field must be meticulously controlled to achieve repeatable, high-quality results. This control, however, is what makes the technology so suitable for mass manufacturing.

Making the Right Choice for Your Goal

Understanding the mechanism allows you to select the right tool for your engineering challenge.

- If your primary focus is high-speed deposition of metals or other conductive materials: DC magnetron sputtering is an industry-standard choice, prized for its high rates, stability, and control.

- If your primary focus is depositing insulating films like oxides or nitrides: You must use a different technique, most commonly RF (Radio Frequency) sputtering, which alternates the voltage to prevent charge buildup on the target.

- If your primary focus is scalability and process repeatability for manufacturing: The control and efficiency offered by the magnetron-enhanced plasma make this an extremely reliable and scalable technology.

Ultimately, the magnetic field's ability to confine plasma is the key innovation that makes DC magnetron sputtering a foundational technology in modern electronics, optics, and materials science.

Summary Table:

| Key Component | Function in DC Magnetron Sputtering |

|---|---|

| Vacuum Chamber | Creates a contaminant-free environment for the process. |

| Inert Gas (Argon) | Ionizes to form the plasma that bombards the target. |

| Conductive Target (Cathode) | Source material; atoms are sputtered off its surface. |

| Magnetic Field | Traps electrons to create a dense plasma, boosting efficiency. |

| Substrate (Anode) | The surface where the sputtered atoms form a thin film. |

Ready to integrate high-performance thin film deposition into your lab?

DC magnetron sputtering is ideal for efficiently coating substrates with conductive materials like metals. KINTEK specializes in providing state-of-the-art lab equipment, including sputtering systems, to meet the precise needs of research and development laboratories.

Contact our experts today to discuss how our reliable sputtering solutions can enhance your material science projects and accelerate your time-to-market.

Visual Guide

Related Products

- HFCVD Machine System Equipment for Drawing Die Nano-Diamond Coating

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 915MHz MPCVD Diamond Machine Microwave Plasma Chemical Vapor Deposition System Reactor

- Laboratory Sterilizer Lab Autoclave Pulse Vacuum Lifting Sterilizer

People Also Ask

- How does a constant temperature shaking incubator support bioleaching for waste PCBs? Optimize Your Metal Recovery

- What temperature does THC evaporate in a vacuum? Master the Distillation Process

- Why must cold traps and drying tubes be configured for WGS gas analysis? Protect Your Micro-GC from Moisture Damage.

- Can carbon fiber be conductive? A Guide to Its Electrical Properties and Risks

- What is pull down time in ULT freezers and what factors affect it? Ensure Your Sample Security with Efficient Cooling

- What are the advantages of CAMI/SPS for W-Cu composite preparation? Reduce cycles from hours to seconds.

- What is the effect of cooling rate on casting? Control Strength, Ductility, and Defects

- What are sintered products used for? From Gears to Medical Implants, Discover Their Versatility