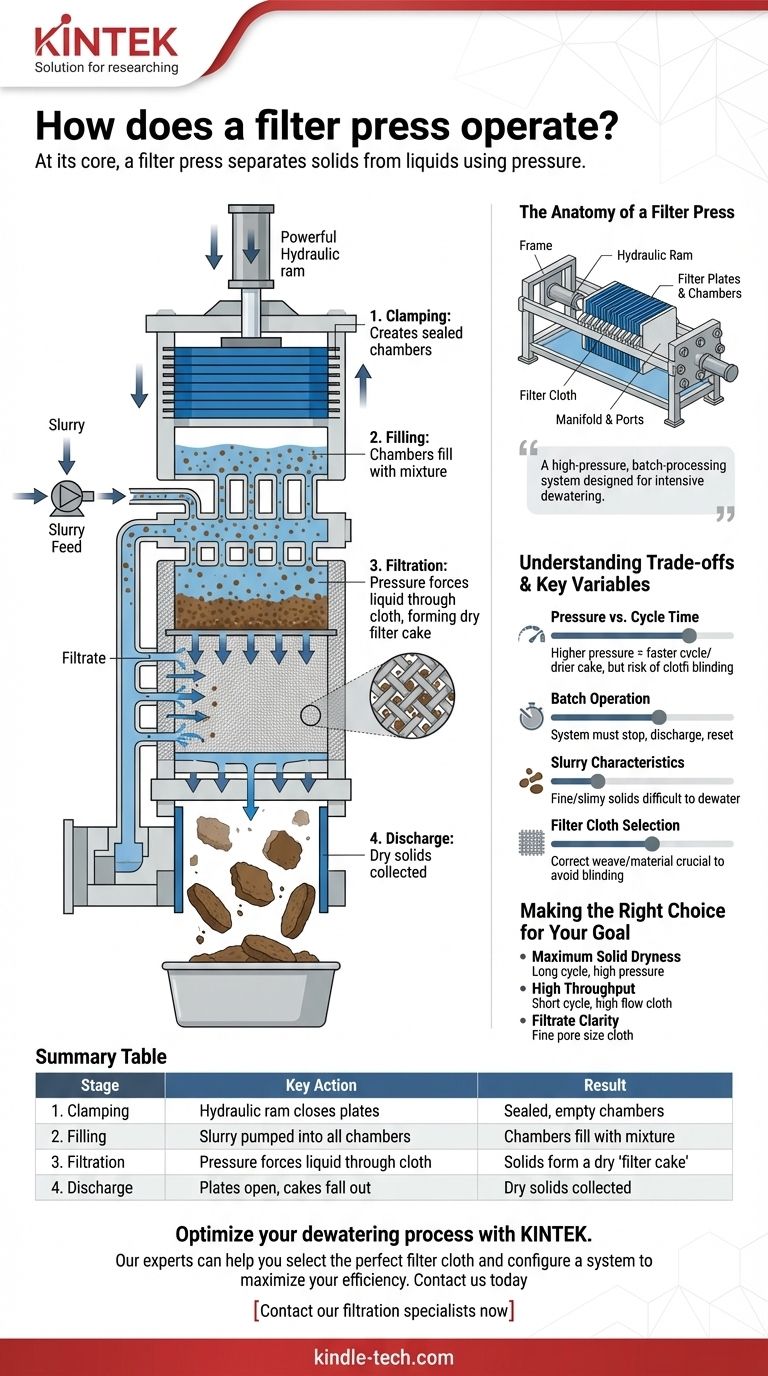

At its core, a filter press separates solids from liquids using pressure. It operates by pumping a slurry (a semi-liquid mixture) into a series of sealed chambers, where a specialized filter cloth captures the solid particles. The immense pressure forces the liquid, or "filtrate," to pass through the cloth and exit the system, leaving behind a compressed, dewatered block of solids known as a "filter cake."

A filter press is not a simple strainer; it is a high-pressure, batch-processing system designed for intensive dewatering. Its effectiveness hinges on transforming a slurry into a densely packed, dry cake by applying mechanical force after the initial filtration is complete.

The Anatomy of a Filter Press

To understand the operation, you must first understand its key components. The machine is a combination of a structural frame, a filtering unit, and a hydraulic system.

The Frame and Hydraulic System

The steel frame is the backbone of the unit, holding the filter plates in place. At one end, a powerful hydraulic ram provides the immense closing force necessary to seal the chambers and withstand the high pressures of the filtration cycle.

Filter Plates and Chambers

Filter plates are the heart of the press. These are recessed plates that, when pressed together, form a series of hollow chambers. Each plate is designed with channels to allow the filtrate to drain away.

The Filter Cloth

Draped over each filter plate is a sheet of filter cloth. This is the actual filter medium, selected specifically for the particle size and chemical characteristics of the slurry being processed. It is what separates the solids from the liquid.

The Manifold and Ports

A manifold acts as the plumbing system. It distributes the incoming slurry evenly to all the chambers and collects the clear filtrate as it exits through ports, which are typically located in the corners of the filter plates.

The Four Stages of the Operating Cycle

The operation of a filter press is a cyclical, four-stage batch process.

Stage 1: Plate Clamping (Closing)

The cycle begins with the empty press. The hydraulic system activates, pushing the moving end of the press to tightly clamp the stack of filter plates together. This creates a watertight seal, forming the empty chambers ready for filling.

Stage 2: Slurry Filling

The feed pump begins to move the slurry into the press, filling all the chambers simultaneously via the manifold. This fill cycle continues until a preset pressure is reached, ensuring solids are distributed evenly on the filter cloths.

Stage 3: Filtration and Cake Formation

As the pump continues to apply pressure, the liquid portion of the slurry is forced through the filter cloth. The solids are too large to pass through and begin to build up on the cloth surface, forming a layer. This initial layer of solids, known as the filter cake, becomes the primary filter.

As more slurry is pumped, the cake grows thicker and more compressed, squeezing out additional liquid. This cycle continues until the chambers are completely full of solid cake and the flow of filtrate nearly stops.

Stage 4: Cake Discharge (Opening)

Once the cycle is complete, the feed pump shuts off. The hydraulic ram retracts, opening the press and separating the filter plates. The dry, compacted filter cakes fall from between the plates, ready for collection and disposal. The press is then ready for the next cycle.

Understanding the Trade-offs and Key Variables

The efficiency of a filter press is not automatic. It depends on a balance of several critical factors.

Pressure vs. Cycle Time

Higher feed pressure generally leads to a faster cycle and a drier cake, but only up to a point. Excessive pressure can blind the filter cloth or damage the equipment, while insufficient pressure will result in a wet, sloppy cake and long cycle times.

Batch Operation

A key limitation of a filter press is its nature as a batch process. The system must stop, discharge its cake, and reset before the next batch can be processed. This is a critical consideration when comparing it to continuous separation technologies.

Slurry Characteristics

The nature of the solids in the slurry is paramount. Fine, slimy, or gelatinous solids are much more difficult to dewater than large, crystalline particles. This directly impacts the choice of filter cloth and the expected cycle time.

Filter Cloth Selection

Choosing the correct filter cloth is the single most important decision. An incorrect weave or material can lead to "blinding" (where particles become permanently lodged in the cloth), poor filtrate clarity, or premature tearing.

Making the Right Choice for Your Goal

Optimizing a filter press operation means tuning its parameters to meet a specific objective.

- If your primary focus is maximum solid dryness: You should prioritize a long cycle time and high final pressures to squeeze out the maximum amount of liquid.

- If your primary focus is high throughput: Your goal is to shorten the cycle. This involves optimizing the feed pressure and choosing a cloth that allows for a high flow rate without sacrificing too much cake quality.

- If your primary focus is filtrate clarity: The critical factor is the filter cloth. You must select a cloth with a pore size and material designed to capture the smallest particles in your slurry.

Understanding these fundamental stages transforms the filter press from a simple machine into a precision tool for solid-liquid separation.

Summary Table:

| Stage | Key Action | Result |

|---|---|---|

| 1. Clamping | Hydraulic ram closes plates | Creates sealed, empty chambers |

| 2. Filling | Slurry pumped into all chambers | Chambers fill with mixture |

| 3. Filtration | Pressure forces liquid through cloth | Solids form a dry 'filter cake' |

| 4. Discharge | Plates open, cakes fall out | Dry solids collected for disposal |

Optimize your dewatering process with KINTEK.

Whether your goal is maximum solid dryness, high throughput, or crystal-clear filtrate, the right equipment is critical. KINTEK specializes in high-performance lab equipment and consumables, including filtration solutions tailored to your specific slurry characteristics and production goals.

Our experts can help you select the perfect filter cloth and configure a system to maximize your efficiency. Contact us today to discuss your solid-liquid separation challenges and discover how we can enhance your laboratory's productivity.

Contact our filtration specialists now

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Hydraulic Diaphragm Lab Filter Press for Laboratory Filtration

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.