A hydraulic press generates immense force by using an incompressible fluid, typically oil, to multiply an initial, smaller force. A pump applies this initial force to the fluid, creating pressure. Because this pressure is distributed evenly throughout the enclosed system, it acts on a much larger piston, resulting in a significantly magnified output force capable of shaping, crushing, or molding materials.

The core principle is not simply pressure, but force multiplication. By applying a small force over a small area, a hydraulic press uses the uniform pressure of a fluid to generate a massive force over a large area, governed by a fundamental law of physics.

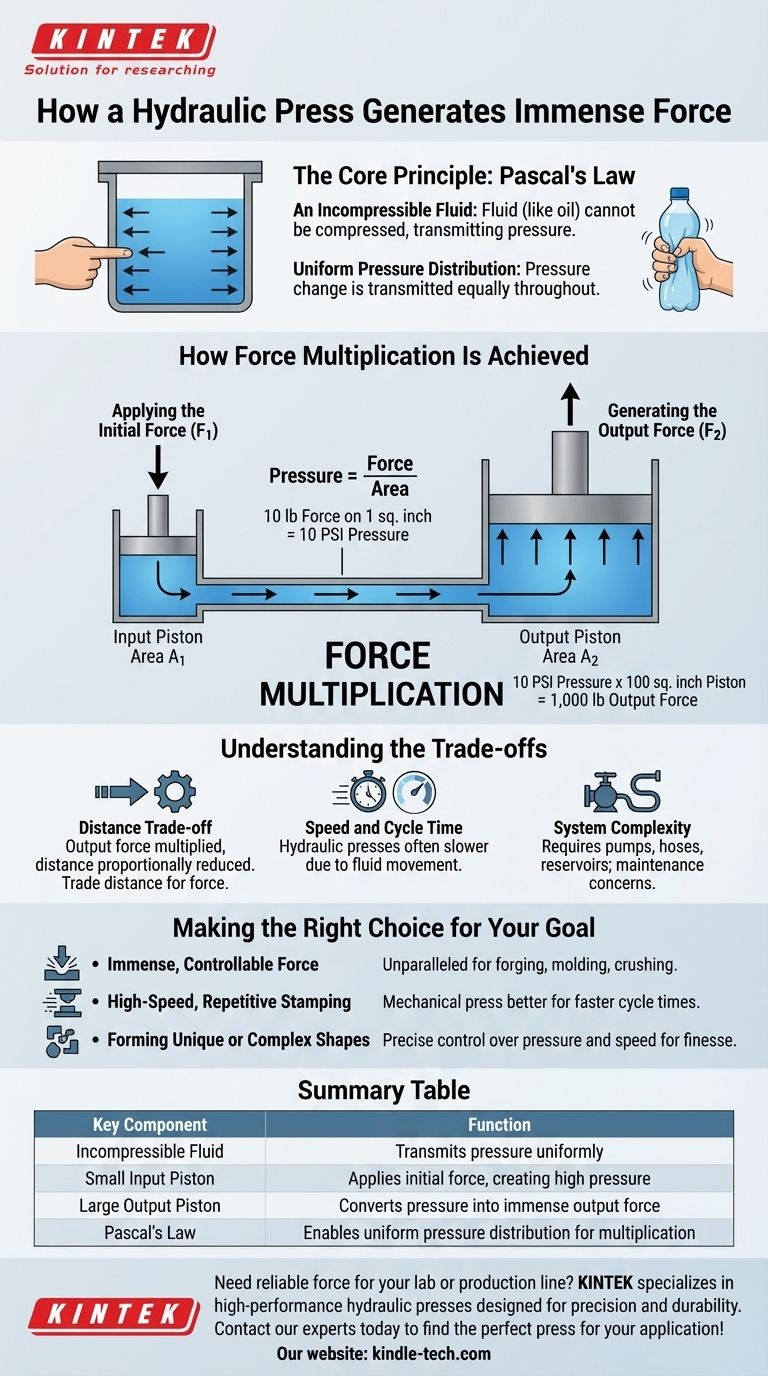

The Core Principle: Pascal's Law

The entire operation of a hydraulic press is a direct application of a principle identified by Blaise Pascal in the 17th century.

An Incompressible Fluid

Hydraulic systems rely on a fluid, usually a specialized oil, that cannot be easily compressed. This is the medium for transferring energy.

When you push on this fluid, it doesn't shrink in volume; instead, it transmits the pressure you've applied.

Uniform Pressure Distribution

Pascal's law states that a pressure change at any point in a confined, incompressible fluid is transmitted equally to every portion of the fluid and the walls of its container.

Imagine squeezing a sealed water bottle. The pressure is felt everywhere inside the bottle, not just where your hand is. This is the principle at work.

How Force Multiplication Is Achieved

The genius of the hydraulic press lies in its simple design, which exploits Pascal's law to create a mechanical advantage.

The Two-Piston System

A basic hydraulic press consists of two connected cylinders, each with its own piston. One cylinder has a small diameter (the input or "master" piston), and the other has a very large diameter (the output or "ram").

Applying the Initial Force

A relatively small force is applied to the small input piston. This force, divided by the area of the piston, creates pressure within the hydraulic fluid (Pressure = Force / Area).

For example, a 10-pound force on a 1-square-inch piston creates 10 pounds per square inch (PSI) of pressure in the fluid.

Generating the Output Force

This pressure is transmitted equally throughout the fluid, pushing against the bottom of the large output piston.

If that large piston has an area of 100 square inches, the 10 PSI of pressure now generates a massive output force of 1,000 pounds (10 PSI * 100 sq. inches). A small input force has been multiplied one hundred times.

Understanding the Trade-offs

This massive force multiplication does not come for free. The design introduces inherent limitations that are critical to understand.

The Distance Trade-off

Energy is conserved. While the output force is multiplied, the distance the large piston travels is proportionally reduced.

To move the 100-square-inch piston up by one inch, you must push the 1-square-inch piston a total distance of 100 inches. You trade distance for force.

Speed and Cycle Time

This distance trade-off means hydraulic presses are often slower than their mechanical counterparts. The pump needs time to move a large volume of fluid to achieve the full travel of the main ram.

System Complexity

Hydraulic systems require pumps, high-pressure hoses, reservoirs, and robust seals to function. Leaks are a constant maintenance concern, and the hydraulic fluid must be kept clean to prevent damage to components.

Making the Right Choice for Your Goal

Understanding this principle helps in deciding when a hydraulic press is the superior tool for an industrial task.

- If your primary focus is immense, controllable force: The hydraulic press is unparalleled for applications like forging, molding, and crushing where raw power is the main requirement.

- If your primary focus is high-speed, repetitive stamping: A mechanical press is often a better choice because it does not have the same distance-for-force trade-off and can achieve much faster cycle times.

- If your primary focus is forming unique or complex shapes: The precise control over pressure and speed offered by hydraulics allows for a level of finesse that is difficult to achieve with other press types.

By mastering the relationship between fluid pressure and surface area, the hydraulic press allows us to reshape the strongest materials with calculated precision.

Summary Table:

| Key Component | Function |

|---|---|

| Incompressible Fluid | Transmits pressure uniformly throughout the system. |

| Small Input Piston | Applies initial force, creating high pressure in the fluid. |

| Large Output Piston | Converts fluid pressure into immense output force. |

| Pascal's Law | Principle that enables uniform pressure distribution for force multiplication. |

Need reliable force for your lab or production line? KINTEK specializes in high-performance lab equipment, including hydraulic presses designed for precision and durability. Whether you're molding, crushing, or forming materials, our solutions deliver the controlled power you need. Contact our experts today to find the perfect press for your application!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

People Also Ask

- What is the law behind the hydraulic press? Understanding Pascal's Law for Immense Force

- What is XRF analysis used for? A Guide to Non-Destructive Elemental Analysis

- Why is a hydraulic press used to apply 380 MPa to battery bilayers? Achieve Superior Density & Safety

- What are the components of hydraulic machines? Master the Core System for Maximum Power

- How does continuous hydraulic pressure affect Ruthenium powder sintering? Control Microstructure & Crystal Alignment.

- What is an example of a mechanical press? Discover the Power of Stamping Presses for High-Volume Production

- What are the two types of presses based on power source? Mechanical vs. Hydraulic Presses Explained

- How do you control pressure in a hydraulic system? Master Flow Resistance for Optimal Performance