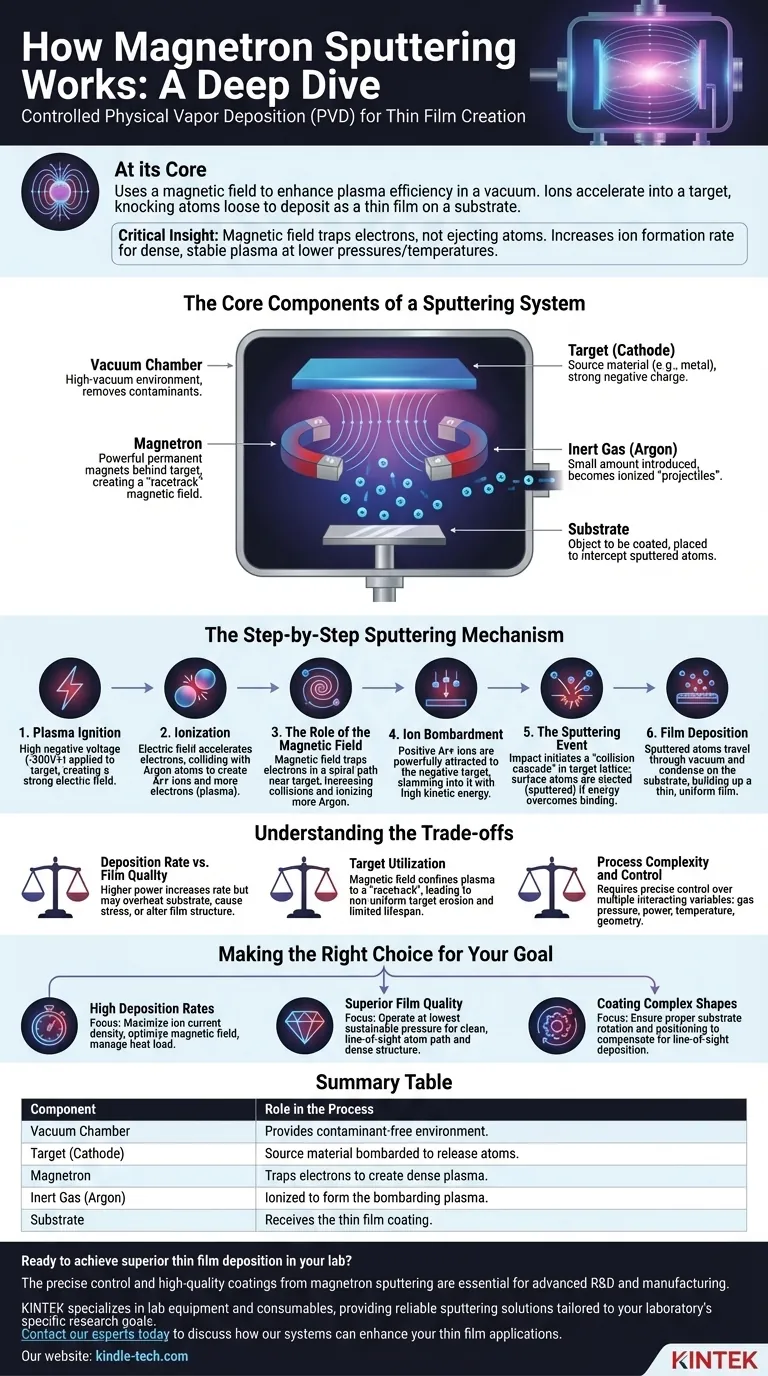

At its core, magnetron sputtering is a highly controlled physical vapor deposition (PVD) process that uses a magnetic field to enhance the efficiency of creating a plasma. In a vacuum, ions from this plasma are accelerated into a source material, called a target, knocking atoms loose. These ejected atoms then travel and deposit onto a component, called the substrate, forming an exceptionally thin and uniform film.

The critical insight is that the magnetic field is not directly involved in ejecting atoms. Instead, it traps electrons near the target, dramatically increasing the rate of ion formation. This creates a dense, stable plasma that allows for rapid and high-quality coating at lower pressures and temperatures than other methods.

The Core Components of a Sputtering System

To understand the process, you must first understand the environment where it occurs. Every magnetron sputtering system is built around a few key components working in concert.

The Vacuum Chamber

The entire process takes place in a high-vacuum chamber. This is non-negotiable, as it removes atmospheric gases and contaminants that would otherwise interfere with the process and contaminate the resulting film.

The Target (Cathode)

This is a solid slab of the material you wish to deposit as a thin film. It is connected to a power supply that gives it a strong negative electrical charge, making it the cathode.

The Substrate

This is the object or material that you intend to coat. It is strategically placed to intercept the atoms ejected from the target.

The Inert Gas

A small, precisely controlled amount of an inert gas, most commonly Argon (Ar), is introduced into the vacuum chamber. This gas will not chemically react with the film, but its atoms will be used as the "projectiles" for bombardment.

The Magnetron

This is the defining component. A set of powerful permanent magnets is placed behind the target. This creates a magnetic field that emerges from the face of the target and loops back around, forming a "tunnel" or "racetrack" on the target's surface.

The Step-by-Step Sputtering Mechanism

With the components in place, the process unfolds in a precise sequence of physical events.

Step 1: Plasma Ignition

A high DC or RF voltage (typically -300V or more) is applied to the target. This strong negative charge creates a powerful electric field that pulls on any free positive charges and repels free electrons.

Step 2: Ionization

The electric field accelerates free electrons, causing them to collide with neutral Argon atoms. These high-energy collisions knock electrons off the Argon atoms, creating two new particles: a positively charged Argon ion (Ar+) and another free electron. This process repeats, creating a self-sustaining cloud of ions and electrons known as a plasma.

Step 3: The Role of the Magnetic Field

This is the key to magnetron sputtering. The magnetic field traps the light, energetic electrons in a spiral path close to the target's surface. This vastly increases the path length of the electrons, making it hundreds of times more likely that they will collide with and ionize more Argon atoms before escaping.

This electron-trapping effect creates a very dense, high-efficiency plasma concentrated directly in front of the target.

Step 4: Ion Bombardment

The newly created positive Argon ions (Ar+) are not significantly affected by the magnetic field due to their much greater mass. However, they are powerfully attracted to the negatively charged target. They accelerate across the plasma sheath and slam into the target surface with tremendous kinetic energy.

Step 5: The Sputtering Event

The impact of an Argon ion is not a simple "chip." It transfers its energy into the target's atomic lattice, initiating a collision cascade. Atoms within the target collide with their neighbors in a chain reaction.

If this cascade reaches a surface atom and transfers enough energy to overcome its surface binding energy, that atom is ejected, or sputtered, from the target.

Step 6: Film Deposition

The sputtered atoms from the target material travel through the low-pressure vacuum chamber until they strike the substrate. Upon arrival, they condense and bond to the surface, gradually building up, atom by atom, into a thin, dense, and highly uniform film.

Understanding the Trade-offs

Magnetron sputtering is a powerful technique, but its application requires understanding its inherent limitations and balancing competing factors.

Deposition Rate vs. Film Quality

Increasing the power to the target increases the ion bombardment energy and density, which raises the deposition rate. However, excessive power can overheat the substrate, introduce stress into the film, or alter its crystalline structure, potentially degrading its performance.

Target Utilization

The magnetic field that makes the process so efficient also confines the plasma to a "racetrack" pattern. This means erosion is not uniform across the target face, leading to a groove being etched over time. This limits the usable life of the target, as only a fraction of its material is consumed before it must be replaced.

Process Complexity and Control

While the principle is straightforward, achieving a specific film property (e.g., electrical resistivity, optical transparency) requires precise control over multiple variables. Gas pressure, power level, substrate temperature, and chamber geometry all interact in complex ways that must be carefully managed.

Making the Right Choice for Your Goal

Understanding the physics of magnetron sputtering allows you to optimize the process for your specific outcome.

- If your primary focus is high deposition rates: The key is to maximize ion current density by optimizing the magnetic field strength and geometry, while managing the heat load on the target and substrate.

- If your primary focus is superior film quality: The key is to operate at the lowest possible pressure the plasma can sustain, ensuring sputtered atoms have a clean, line-of-sight path to the substrate to form a dense, defect-free structure.

- If your primary focus is coating complex shapes: The key is to ensure proper substrate rotation and positioning relative to the target to compensate for the line-of-sight nature of the deposition and achieve uniform coverage.

By controlling the interplay of electricity, magnetism, and vacuum, magnetron sputtering empowers the creation of advanced materials that define modern technology.

Summary Table:

| Component | Role in the Process |

|---|---|

| Vacuum Chamber | Provides a contaminant-free environment for deposition. |

| Target (Cathode) | The source material that is bombarded to release coating atoms. |

| Magnetron | Traps electrons with a magnetic field to create a dense plasma. |

| Inert Gas (Argon) | Ionized to form the plasma that bombards the target. |

| Substrate | The surface that receives the thin film coating. |

Ready to achieve superior thin film deposition in your lab? The precise control and high-quality coatings from magnetron sputtering are essential for advanced R&D and manufacturing. KINTEK specializes in lab equipment and consumables, providing reliable sputtering solutions tailored to your laboratory's specific research goals. Contact our experts today to discuss how our systems can enhance your thin film applications.

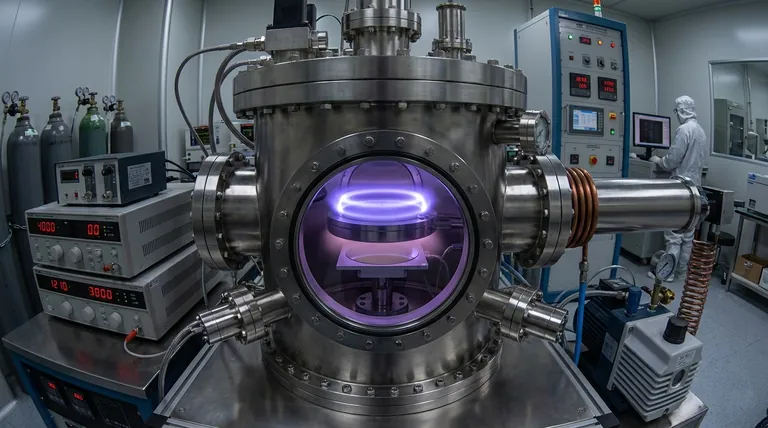

Visual Guide

Related Products

- E Beam Crucibles Electron Gun Beam Crucible for Evaporation

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- Spark Plasma Sintering Furnace SPS Furnace

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Lab-Scale Vacuum Induction Melting Furnace

People Also Ask

- What are the benefits of RF sputtering? Versatile, Stable Thin-Film Deposition

- Can graphite withstand high-temperature? Maximizing Performance in Controlled Atmospheres

- Why is the metal melting temperature important? The Key to Manufacturing & Performance

- What is the function of a high-speed magnetic stirring system? Enhancing Corn Cob Hydrolysis Yields

- What is the industrial application of graphite as lubricant? A Guide to Extreme Heat & Pressure Solutions

- What are the disadvantages of a screw compressor? Key Trade-offs to Consider Before Buying

- What are the requirements for polymer foam templates for reticulated MAX phase ceramics? Ensure Structural Integrity

- What machine is used for cutting diamond? Discover the Laser Technology That Shapes Gems