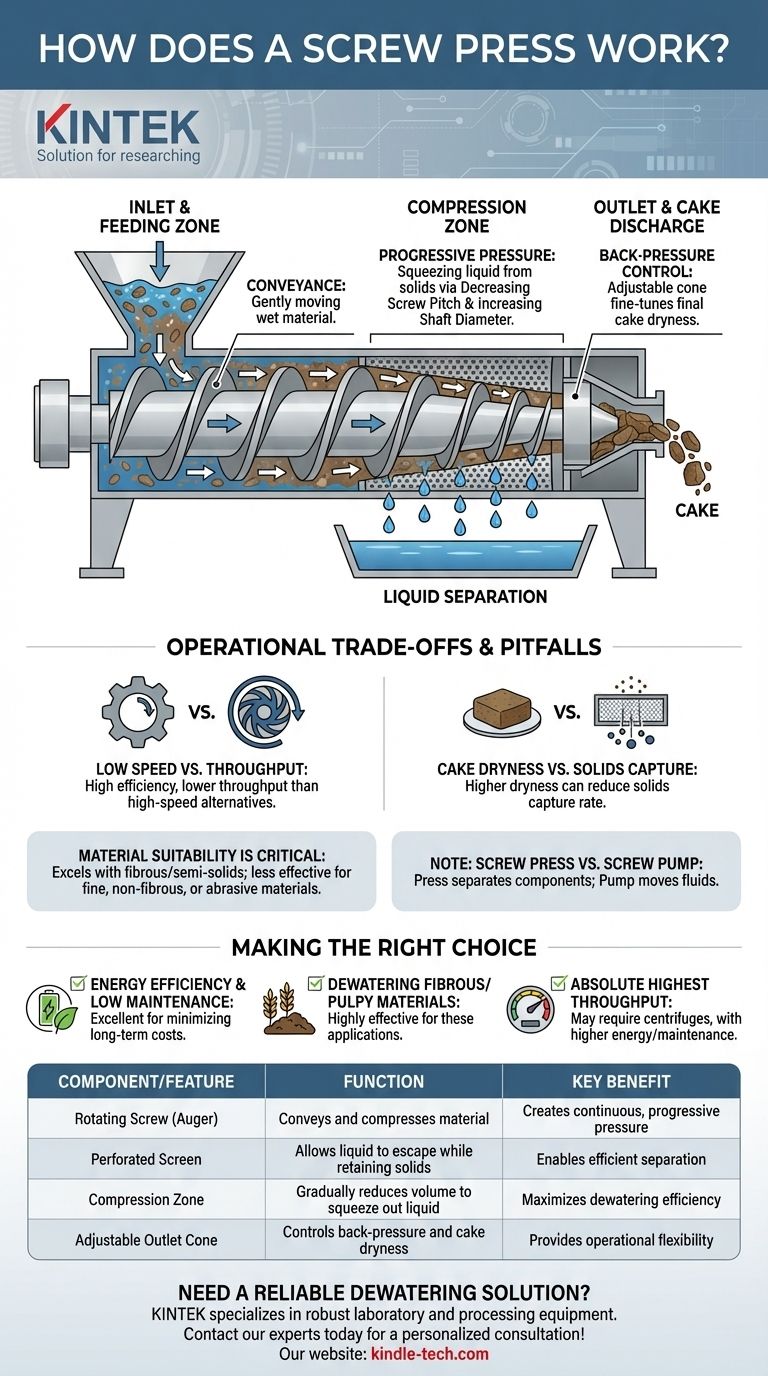

At its core, a screw press is a simple and robust machine that separates liquids from solids through continuous mechanical pressure. It uses a rotating helical screw (an auger) inside a perforated cylindrical screen. As material is fed into the press, the screw conveys it forward, gradually compressing it and forcing the liquid out through the screen while the dewatered solid, known as "cake," is discharged at the end.

The true effectiveness of a screw press lies not just in simple rotation, but in its sophisticated design that creates progressively increasing pressure. This allows for the efficient and low-energy dewatering of a wide range of materials.

The Mechanical Principle: From Conveyance to Compression

Understanding a screw press is understanding how it builds pressure along the length of the screw. The process is divided into distinct zones, each with a specific function.

The Inlet and Feeding Zone

Material is introduced into the press at the inlet or hopper. In this initial section, the screw flights are widely spaced. The primary function here is not compression, but conveyance—gently moving the wet material away from the inlet and into the main body of the press.

The Compression Zone: The Key to Dewatering

This is where the separation happens. As the material moves along the screw, the available space for it becomes progressively smaller. This reduction in volume is what creates the high pressure needed to squeeze liquid from the solids.

Engineers achieve this increasing pressure primarily in two ways:

- Decreasing Screw Pitch: The distance between the helical screw flights becomes shorter, forcing the same amount of material into a smaller space.

- Increasing Shaft Diameter: The central shaft of the screw becomes progressively thicker, reducing the volume between the shaft and the outer screen.

Most modern screw presses use a combination of these designs to ensure a gradual and consistent pressure increase, which prevents the screen from clogging and maximizes dewatering efficiency.

The Outlet and Cake Discharge

At the end of the press, the dewatered solid cake is discharged. An adjustable cone or restriction plate at the outlet creates back-pressure. By tightening or loosening this cone, operators can fine-tune the final pressure, directly controlling the dryness of the discharged cake.

Understanding the Trade-offs and Common Pitfalls

While highly effective, screw presses are not a universal solution. Understanding their operational trade-offs is critical for proper application.

Low Speed vs. Throughput

Screw presses are low-speed, high-torque machines. This makes them extremely energy-efficient and reduces wear. However, this inherently means their throughput (volume processed per hour) is often lower than high-speed alternatives like centrifuges.

Cake Dryness vs. Solids Capture

There is a direct trade-off between the dryness of the output cake and the solids capture rate. Applying extreme pressure to achieve a very dry cake can force fine solid particles through the screen along with the liquid. This lowers the overall efficiency of solids capture. The key is to find the optimal balance for your specific material and goals.

Material Suitability Is Critical

Screw presses excel with fibrous or semi-solid materials like municipal sludge, food processing waste, and agricultural pulp. They are less effective for materials with very fine, non-fibrous particles or those that are extremely abrasive, which can cause premature wear on the screw and screen.

A Note on Screw Pumps

It's important to distinguish a screw press from a screw pump. While both use a helical screw, a pump is designed to move fluids (liquids or gases) from one point to another. A press is designed specifically to apply pressure to a material to separate its liquid and solid components.

Making the Right Choice for Your Application

Selecting the right dewatering technology depends entirely on your operational priorities.

- If your primary focus is energy efficiency and low maintenance: The simple, robust, low-speed design of a screw press makes it an excellent choice for minimizing long-term operating costs.

- If your primary focus is dewatering fibrous or pulpy materials: A screw press is one of the most effective and widely used technologies for these applications.

- If your primary focus is achieving the absolute highest throughput: You may need to evaluate higher-speed technologies like centrifuges, but be prepared for higher energy consumption and maintenance complexity.

By understanding the core principle of progressive pressure, you can accurately determine if a screw press is the optimal tool for your specific separation goals.

Summary Table:

| Component/Feature | Function | Key Benefit |

|---|---|---|

| Rotating Screw (Auger) | Conveys and compresses material | Creates continuous, progressive pressure |

| Perforated Screen | Allows liquid to escape while retaining solids | Enables efficient separation |

| Compression Zone | Gradually reduces volume to squeeze out liquid | Maximizes dewatering efficiency |

| Adjustable Outlet Cone | Controls back-pressure and cake dryness | Provides operational flexibility |

Need a reliable and energy-efficient solution for dewatering fibrous materials like sludge or food waste?

KINTEK specializes in robust laboratory and processing equipment. Our expertise can help you select the ideal screw press to optimize your separation process, reduce operating costs, and improve efficiency.

Contact our experts today for a personalized consultation and discover the right dewatering solution for your application!

Visual Guide

Related Products

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

- Touchscreen Automatic Vacuum Heat Press

- Rubber Vulcanizer Vulcanizing Machine Plate Vulcanizing Press for Lab

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Cold Isostatic Pressing Machine CIP for Small Workpiece Production 400Mpa

People Also Ask

- What role does a laboratory hydraulic press play in all-solid-state battery fabrication? Enhancing Ion Conductivity

- What is the function of a laboratory hydraulic hot press in the assembly of solid-state photoelectrochemical cells?

- What does a hydraulic heat press do? Achieve Industrial-Scale, Consistent Pressure for High-Volume Production

- How is a laboratory hydraulic press used for LLZTO pellets? Achieve 93% Density in Solid-State Battery Research

- What is the purpose of applying high pressure in dry cathode preparation? Achieve Peak Solid-State Battery Density