At its core, a vulcanizing machine is a specialized press that applies controlled heat and pressure to a rubber compound. This process isn't merely for shaping; it initiates a crucial chemical reaction called vulcanization. This transformation is what converts soft, sticky raw rubber into the strong, durable, and elastic material used in everything from tires to seals.

The machine's function is best understood not as simple heating and pressing, but as creating a controlled environment for a chemical reaction. It works by using a hydraulic system to generate immense pressure on a mold, while a heating system provides the precise thermal energy needed to activate sulfur cross-linking between rubber polymer chains.

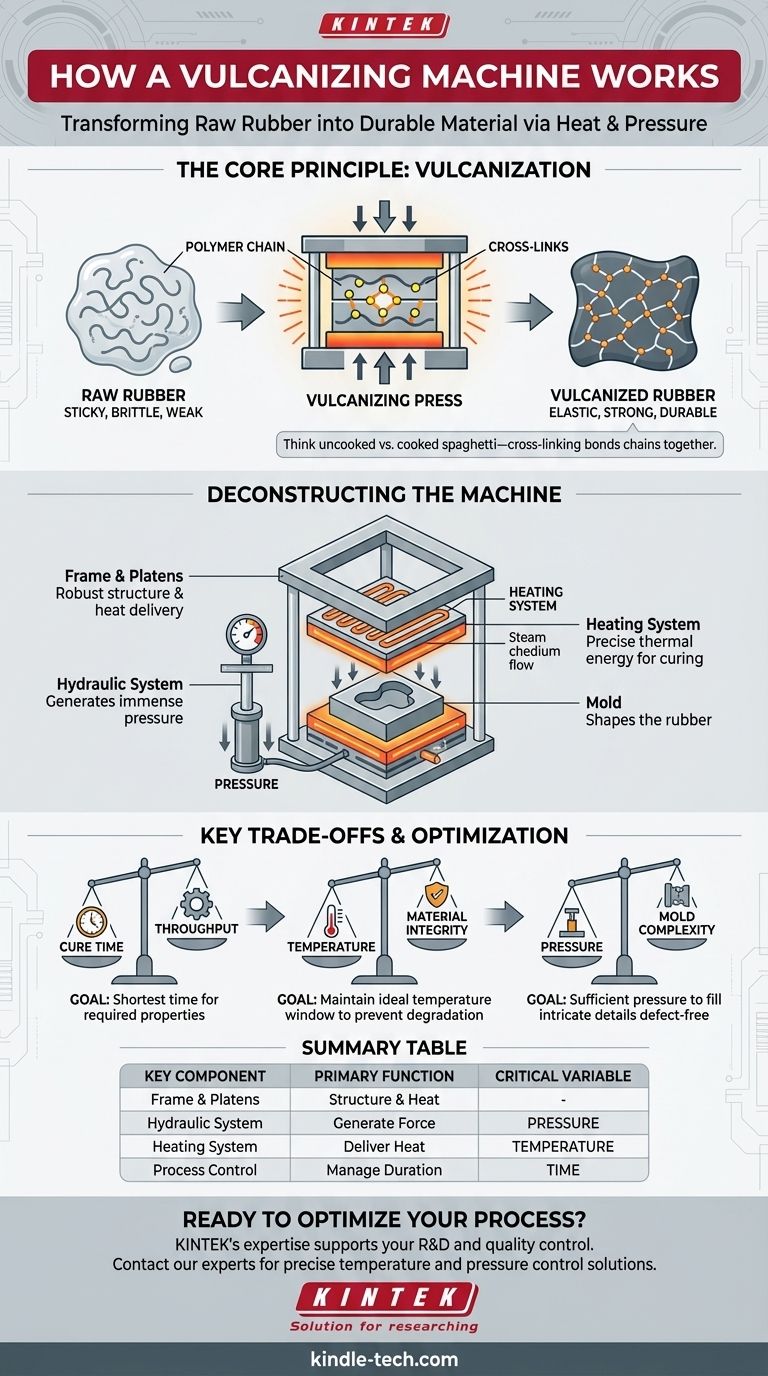

The Principle of Vulcanization: From Goo to Grip

To understand how the machine works, we must first understand the problem it solves. Raw, uncured rubber has very limited practical use.

The Weakness of Raw Rubber

Natural or synthetic raw rubber is composed of long, separate polymer chains. This structure makes it sticky when warm, brittle when cold, and prone to permanently deforming under stress.

The Chemical Solution: Cross-Linking

Vulcanization introduces a curing agent, most commonly sulfur, into the rubber. When heated, the sulfur atoms form strong chemical bridges, or cross-links, between the individual polymer chains.

Think of the raw rubber as a plate of uncooked spaghetti strands—they can slide past each other easily. Vulcanization is like cooking that spaghetti, causing the strands to stick together into a single, cohesive mass that can be stretched but will snap back to its original shape.

The Resulting Properties

This cross-linked molecular structure is what gives vulcanized rubber its most valuable properties:

- Elasticity: The ability to return to its original shape after being deformed.

- Tensile Strength: Resistance to being pulled apart.

- Durability: Resistance to abrasion, wear, and temperature extremes.

Deconstructing the Vulcanizing Machine

Every component of the vulcanizing machine is designed to manage the three critical variables of this process: pressure, temperature, and time.

The Frame and Platens

The machine is built on a heavy, robust steel frame designed to withstand the immense forces involved. Within this frame are the platens—thick, flat steel plates that press the mold together.

The Pressure System

Pressure ensures the raw rubber flows into every detail of the mold and eliminates air bubbles. This is almost always achieved with a hydraulic system.

A hydraulic cylinder, powered by pressurized oil, drives a ram that pushes the platens together. This system multiplies force, allowing a small pump to generate the thousands of pounds of pressure needed for effective molding.

The Heating System

Temperature is the catalyst for the vulcanization reaction. The platens are heated internally to provide consistent and uniform thermal energy to the mold.

This is typically done using a heating medium like high-pressure steam or specialized heat-transfer oil that circulates through channels drilled inside the platens. Precise temperature control is crucial; too little heat results in an incomplete cure, while too much can scorch and degrade the rubber.

The Mold

The mold is the tool that gives the rubber its final desired shape. It is placed between the heated platens, and the machine's primary job is to clamp it shut with enough force and heat to cure the rubber inside.

Understanding the Key Trade-offs

Optimizing the vulcanization process is a balancing act. Mismanaging any of the core variables can lead to product failure.

Cure Time vs. Throughput

A longer cure time can create more cross-links, potentially increasing strength. However, this directly reduces factory output. The goal is to find the shortest possible cycle time that still achieves the required physical properties.

Temperature vs. Material Integrity

Higher temperatures can speed up the curing reaction, but they also increase the risk of "reversion," where the polymer chains begin to break down, weakening the final product. Each rubber compound has an ideal temperature window that must be strictly maintained.

Pressure vs. Mold Complexity

Simple parts may not require extreme pressure. However, for intricate designs with fine details, high pressure is non-negotiable to ensure the material completely fills the mold cavity and produces a defect-free part.

Making the Right Choice for Your Goal

The specific parameters you use on a vulcanizing machine depend entirely on the intended application of the final product.

- If your primary focus is high-performance automotive tires: You will prioritize perfect uniformity in temperature and pressure to ensure consistent wear and safety.

- If your primary focus is producing simple, high-volume gaskets: You will optimize for the shortest possible cure time that meets basic sealing specifications to maximize throughput.

- If your primary focus is manufacturing complex vibration dampeners: Your main concern will be ensuring the hydraulic system provides enough consistent pressure to fully fill intricate mold geometries.

Ultimately, a vulcanizing machine is a precision tool for controlling a chemical reaction, transforming a raw material's potential into a product's reliable performance.

Summary Table:

| Key Component | Primary Function | Critical Variable |

|---|---|---|

| Frame & Platens | Provides a robust structure to withstand immense pressure | N/A |

| Hydraulic System | Generates the force to press the mold shut and eliminate air bubbles | Pressure |

| Heating System | Delivers precise thermal energy to activate the vulcanization reaction | Temperature |

| Process Control | Manages the duration of the heating and pressing cycle | Time |

Ready to Optimize Your Rubber Manufacturing Process?

Choosing the right vulcanizing parameters is critical for product quality and throughput. Whether you're producing high-performance tires, durable seals, or complex molded parts, KINTEK's expertise in lab equipment and consumables can support your R&D and quality control efforts.

Contact our experts today to discuss how our solutions can help you achieve precise temperature and pressure control for superior vulcanization results.

Visual Guide

Related Products

- Rubber Vulcanizer Vulcanizing Machine Plate Vulcanizing Press for Lab

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press 25T 30T 50T

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- What is the difference between lamination and co-extrusion? Achieve Superior Material Performance

- What is a two-roll differential speed mill? Achieve Superior Polymer Mixing & Dispersion

- What is the manufacturing process of rubber molding? Injection, Compression, or Transfer Molding?

- What is the difference between calendaring and calendering? Master the Key Spelling and Context

- What is the process of double extrusion? Create Integrated Multi-Material Components

- What is the working principle of rolling mill? It Depends on Your Material Processing Goal

- What is the role of high-speed melt mixing equipment? Key to RPE/CSPE Thermoplastic Elastomer Synthesis

- What is an internal screw mixer? A Guide to Gentle, Efficient Powder Blending