In short, Hot Isostatic Pressing (HIP) reduces porosity by subjecting a material to extremely high, uniform pressure and elevated temperature simultaneously. This combination causes internal voids or pores within the material to physically collapse and diffusionally weld shut, resulting in a fully dense, stronger final part.

The critical insight is that HIP uses an inert gas to apply isostatic (equal from all directions) pressure, which closes internal defects without distorting the component's overall shape. It's not just heat and pressure; it's the uniformity of that pressure that makes the process so effective.

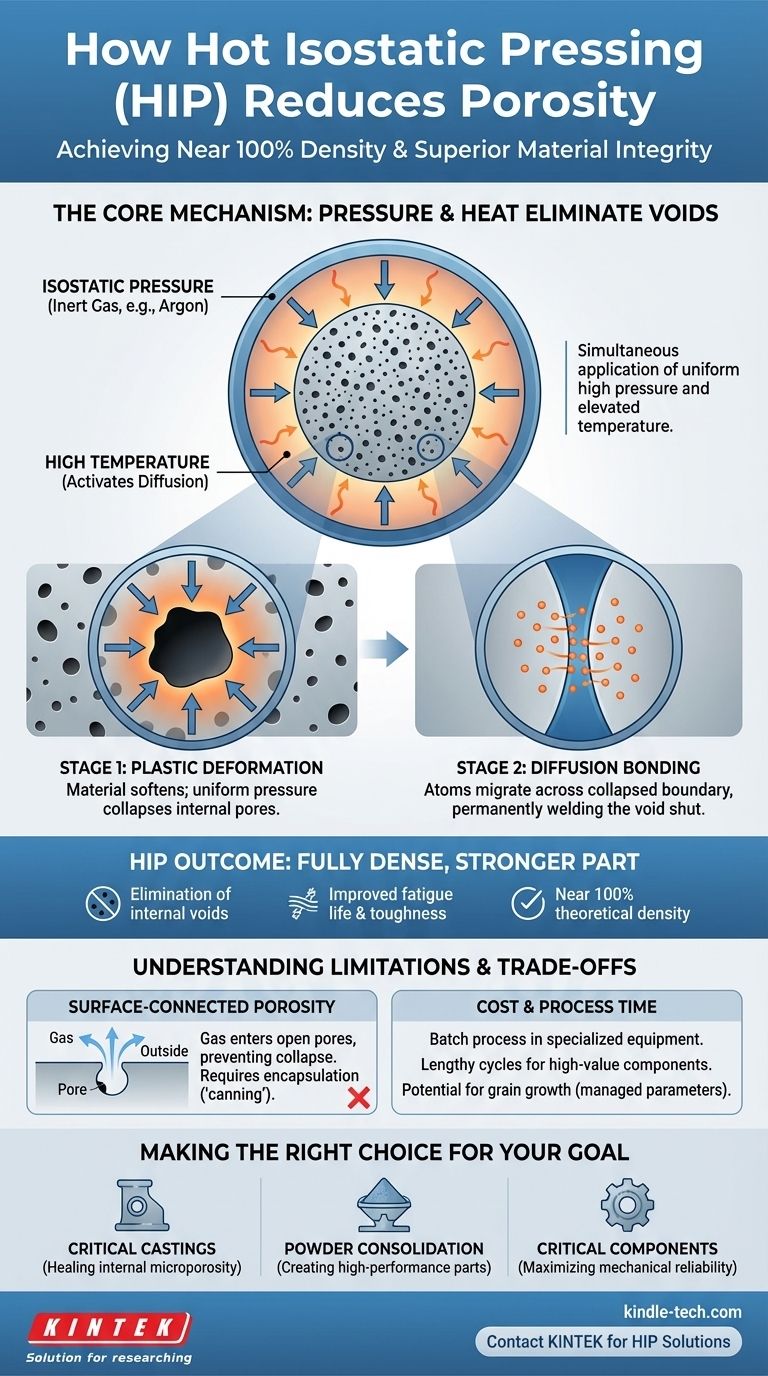

The Core Mechanism: How Pressure and Heat Eliminate Voids

Hot Isostatic Pressing is a material densification process that relies on two fundamental physical principles working in concert: plastic deformation and solid-state diffusion.

The Role of High Temperature

The first step is heating the component in a vacuum-sealed, high-pressure vessel. This thermal energy is critical.

Elevated temperature softens the material, reducing its yield strength and making it malleable. This prepares the material's internal structure to be reshaped by the applied pressure.

Most importantly, heat activates atomic movement. Atoms gain the energy to move from one position in the crystal lattice to another, a process known as diffusion. This is the key to permanently healing the voids.

The Role of Isostatic Pressure

Once the material is at the target temperature, an inert gas (typically Argon) is pumped into the vessel, creating immense pressure.

This pressure is isostatic, meaning it is applied to the component with equal force from all directions. This uniform compaction is what causes internal pores to collapse.

Because the pressure differential is much higher outside the void than inside, the surrounding material is forced inward, closing the gap. This is the plastic deformation stage.

The Final Stage: Diffusion Bonding

With the void now physically collapsed, the high temperature allows atoms from the opposing surfaces to migrate across the boundary.

This diffusion bonding effectively welds the former void shut on an atomic level, creating a strong metallurgical bond. The original pore is not just filled; it is completely eliminated from the material's microstructure.

The result is a component with near 100% of its theoretical density, leading to dramatically improved mechanical properties like fatigue life, toughness, and ductility.

Understanding the Trade-offs and Limitations

While incredibly powerful, HIP is not a universal solution. Understanding its limitations is key to using it effectively.

Surface-Connected Porosity Cannot Be Healed

The most critical limitation of HIP is that it can only close internal, isolated pores.

If a pore is connected to the surface of the part, the high-pressure gas will enter the void, equalizing the pressure inside and out. With no pressure differential, the pore cannot be collapsed.

Parts with surface-connected porosity must first be encapsulated in a disposable, airtight container (a process known as "canning") before undergoing HIP.

Cost and Process Time

HIP is a batch process performed in specialized, high-cost equipment. This makes it more expensive than standard heat treatments.

The process cycles, including heating, pressurization, hold time, and cooling, can be lengthy, often lasting several hours. This makes it best suited for high-value or performance-critical components.

Potential for Microstructural Changes

The combination of high heat and time can lead to grain growth in some materials. While the process parameters are carefully controlled to minimize this, it is a factor that engineers must consider during material and process selection.

Making the Right Choice for Your Goal

Deciding whether to specify HIP depends entirely on the nature of the defects you need to eliminate and the performance requirements of your component.

- If your primary focus is healing internal defects in critical castings: HIP is the industry-standard solution for eliminating microporosity to vastly improve fatigue life and mechanical reliability.

- If you are consolidating metal or ceramic powders into a fully dense solid: HIP is a primary manufacturing method for creating high-performance, near-net-shape parts from advanced materials.

- If you are dealing primarily with surface-level voids or cracks: Investigate other methods like welding, brazing, or surface sealing, as HIP will not be effective without costly encapsulation.

By understanding these principles, you can confidently leverage Hot Isostatic Pressing to achieve a level of material integrity that is otherwise unattainable.

Summary Table:

| HIP Process Step | Key Function | Outcome |

|---|---|---|

| High Temperature | Softens material & activates atomic diffusion | Prepares material for deformation and bonding |

| Isostatic Pressure | Applies uniform force from all directions | Collapses internal pores via plastic deformation |

| Diffusion Bonding | Atoms migrate across collapsed void boundaries | Permanently welds the void shut, achieving near-100% density |

Ready to eliminate porosity and enhance the performance of your critical components?

KINTEK specializes in advanced thermal processing solutions, including Hot Isostatic Pressing systems and services. Our expertise in lab equipment and consumables is tailored to meet the demanding needs of laboratories and manufacturers working with high-performance materials.

We can help you achieve superior material density, improved fatigue life, and greater mechanical reliability. Let's discuss how HIP can benefit your specific application.

Contact our experts today for a personalized consultation!

Visual Guide

Related Products

- Warm Isostatic Press WIP Workstation 300Mpa for High Pressure Applications

- Warm Isostatic Press for Solid State Battery Research

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Automatic Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

People Also Ask

- Why is a Hot Isostatic Press (HIP) required for Eu:Y2O3 samples? Unlock Optical-Grade Ceramic Transparency

- What is the HIP process of casting? Transform Castings into High-Performance Components

- What is the temperature of a warm isostatic press? Achieve Optimal Densification for Your Materials

- What are the conditions for hot isostatic pressing? Unlock Maximum Material Density

- How do warm isostatic presses improve dry electrode performance? Enhance ASSB Conductivity with Heat & Pressure

- How does Hot Isostatic Press (HIP) enhance Si3N4 and h-BN ceramics? Achieving Full Density and Isotropy

- What is the meaning of Hot Isostatic Pressing? Achieve 100% Density and Superior Material Integrity

- What are the advantages of HIP over conventional PM? Achieve Full Density for Superior Performance