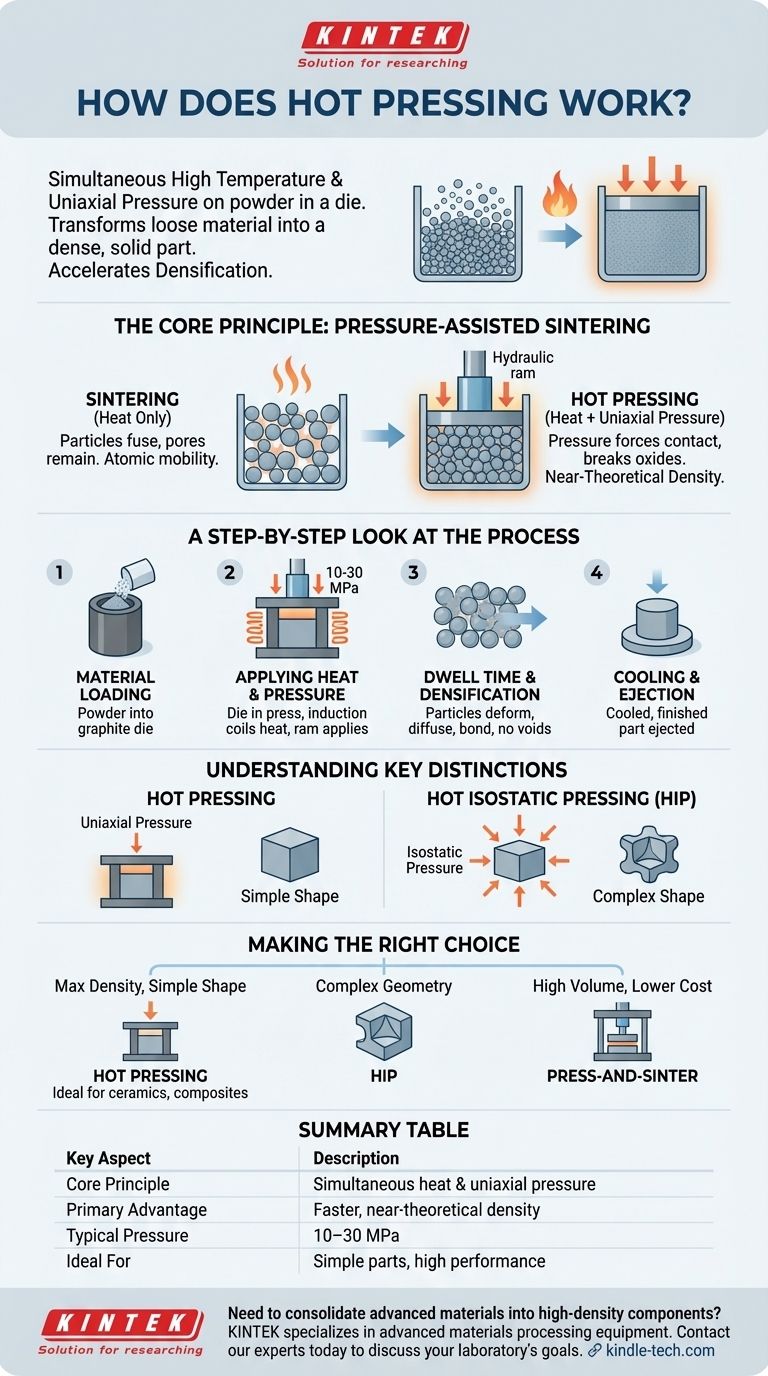

At its core, hot pressing is a materials processing technique that simultaneously applies high temperature and uniaxial pressure to a powder. This combination forces the individual powder particles to consolidate and bond, transforming the loose material into a dense, solid part. The process takes place within a simple shaped die, which contains the powder and gives the final component its basic form.

The fundamental advantage of hot pressing is its ability to accelerate densification. By applying pressure during the heating cycle, it achieves near-perfect material density in a fraction of the time and often at lower temperatures than required by sintering alone.

The Core Principle: Pressure-Assisted Sintering

To understand how hot pressing works, it's best to see it as an enhanced version of a more common process called sintering.

The Baseline: Sintering

Sintering is the process of using heat to fuse particles together without melting them. The high temperature makes the atoms in the particles mobile, allowing them to diffuse across the boundaries of neighboring particles, forming strong bonds and gradually eliminating the empty spaces, or pores, between them.

The Enhancement: Adding Uniaxial Pressure

Hot pressing introduces a powerful second variable: uniaxial pressure. This is a directional force, typically applied from the top and bottom by a ram, that physically compacts the powder.

This pressure dramatically improves the densification process. It forces the powder particles into intimate contact, breaking down surface oxides and increasing the surface area available for atomic diffusion to occur.

The Result: Near-Theoretical Density

The synergy between heat and pressure is what makes hot pressing so effective. The heat makes the material pliable and promotes atomic bonding, while the pressure squeezes out the remaining porosity.

This dual-action approach allows the final product to reach a density that is extremely close to the material's theoretical maximum, resulting in superior mechanical properties, such as strength and hardness.

A Step-by-Step Look at the Process

While specific parameters vary by material, the general workflow for hot pressing follows a clear sequence.

1. Material Loading

The process begins by placing the final additive powder into a die. This die is often made of graphite because it can withstand extreme temperatures, conducts heat well, and is relatively easy to machine.

2. Applying Heat and Pressure

The die assembly is placed inside the hot press. The system then begins to heat the die, often using induction coils, while a hydraulic ram applies a constant, controlled pressure, typically in the range of 10–30 MPa.

3. Dwell Time and Densification

The material is held at the target temperature and pressure for a specific period, known as the "dwell time." During this stage, the combined forces cause the particles to deform, diffuse, and bond, eliminating voids and solidifying the component.

4. Cooling and Ejection

Once densification is complete, the system is cooled in a controlled manner, and the pressure is released. The finished, dense part is then ejected from the die.

Understanding Key Distinctions

The term "hot press" can be used in different contexts, so it's critical to distinguish it from related technologies.

Hot Pressing vs. Hot Isostatic Pressing (HIP)

The key difference is the nature of the pressure. Hot pressing uses uniaxial pressure (from one direction). Hot Isostatic Pressing (HIP) uses isostatic pressure, applying equal force from all directions using a high-pressure gas. This allows HIP to produce parts with far more complex geometries.

Hot Pressing vs. Woodworking Lamination

The term is also used for machines that laminate wood veneers or plastics using heat and pressure. While conceptually similar, these processes operate at much lower temperatures and pressures and often involve adhesives, which is fundamentally different from the metallurgical bonding that occurs in powder consolidation.

Making the Right Choice for Your Goal

Selecting the correct manufacturing process depends entirely on the requirements of your final component.

- If your primary focus is achieving maximum density and mechanical performance in a simple shape: Hot pressing is an exceptional choice, especially for advanced ceramics and composites where eliminating porosity is critical.

- If your primary focus is producing geometrically complex parts: You should evaluate Hot Isostatic Pressing (HIP), which is not limited by a rigid die and can densify intricate shapes.

- If your primary focus is high-volume, lower-cost production: A traditional "press-and-sinter" method, where parts are first compacted at room temperature and then heated in a separate step, may be more economical.

Ultimately, choosing the right densification technology is a matter of balancing your component's performance requirements against its geometric complexity and production cost.

Summary Table:

| Key Aspect | Description |

|---|---|

| Core Principle | Simultaneous application of heat and uniaxial pressure to a powder in a die. |

| Primary Advantage | Achieves near-theoretical density faster and at lower temperatures than sintering alone. |

| Typical Pressure Range | 10–30 MPa |

| Ideal For | Simple-shaped parts requiring superior mechanical properties (e.g., advanced ceramics, composites). |

Need to consolidate advanced materials into high-density components?

KINTEK specializes in the precise lab equipment required for advanced materials processing, including the tools and expertise for techniques like hot pressing. Our solutions help you achieve superior material density and performance for your R&D and production needs.

Contact our experts today to discuss how we can support your laboratory's material densification goals.

Visual Guide

Related Products

- Vacuum Hot Press Furnace Machine for Lamination and Heating

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

- Small Vacuum Heat Treat and Tungsten Wire Sintering Furnace

- Graphite Vacuum Furnace IGBT Experimental Graphitization Furnace

People Also Ask

- Why is a heated laboratory hydraulic press necessary for composite laminates? Achieve Void-Free Structural Integrity

- What are the advantages and disadvantages of hot pressing? Choose the Right Powder Metallurgy Process

- Why is a vacuum hot-pressing furnace preferred for C_fiber/Si3N4 composites? Achieve High Density & Fiber Protection

- What is the advantage by using hot press forming? Achieve Stronger, More Complex Parts

- What is the purpose of laminating? Protect and Enhance Your Documents for Long-Term Use