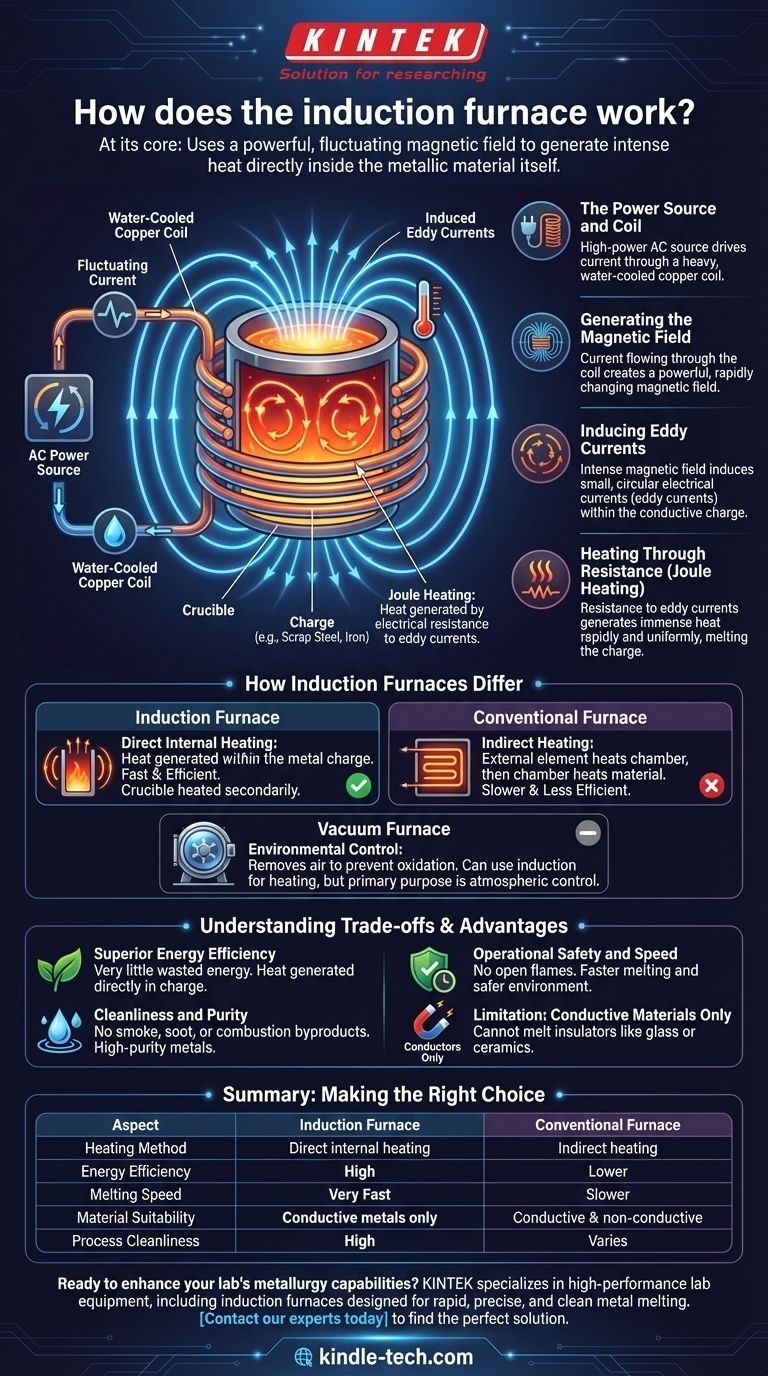

At its core, an induction furnace operates without flames or external heating elements touching the metal. It uses a powerful, fluctuating magnetic field to generate intense heat directly inside the metallic material itself, causing it to melt with remarkable speed and precision.

The defining principle of an induction furnace is its ability to turn the metal into its own heat source. By inducing electrical currents within the conductive charge, it bypasses the inefficiencies of conventional heating, offering superior control, cleanliness, and energy efficiency.

The Core Principle: Electromagnetic Induction

The process of induction heating is a direct application of Faraday's Law of Induction and the Joule heating effect. It converts electrical energy into a magnetic field and then back into thermal energy within the target material.

The Power Source and Coil

An induction furnace begins with a high-power alternating current (AC) source. This current is channeled through a heavy, multi-turn copper coil that is almost always water-cooled to prevent it from melting.

Generating the Magnetic Field

As the AC flows through the coil, it generates a powerful and rapidly changing magnetic field in the space within and around the coil. The frequency of the alternating current dictates the characteristics of this magnetic field.

Inducing Eddy Currents

A conductive material, known as the charge (e.g., scrap steel, iron, or other metals), is placed inside a container, or crucible, within the coil. The intense magnetic field penetrates the charge, inducing small, circular electrical currents within the metal. These are called eddy currents.

Heating Through Resistance (Joule Heating)

All metals have some natural electrical resistance. As the induced eddy currents flow through the metal, they encounter this resistance, which generates immense heat. This phenomenon, known as Joule heating, raises the temperature of the charge rapidly and uniformly, causing it to melt.

How Induction Furnaces Differ from Other Furnaces

The "direct internal heating" method sets induction furnaces apart from other common industrial heating technologies. Understanding this difference is key to appreciating their specific applications.

Versus Conventional (Tube or Resistance) Furnaces

A conventional furnace works by heating an element with electricity or fuel. This element then heats the furnace chamber, which in turn slowly transfers heat to the material inside. This is an indirect heating process, heating from the outside in.

Versus Vacuum Furnaces

A vacuum furnace is defined by its environment, not its heating method. It removes air to create a vacuum, which prevents oxidation and contamination during heating. While some vacuum furnaces use induction heating, the primary purpose is atmospheric control, whereas induction is purely a heating mechanism.

The Key Advantage: Direct Heating

Because heat is generated within the metal charge, the process is extremely fast and efficient. The furnace walls and crucible are only heated secondarily by contact with the molten metal, not by the primary energy source.

Understanding the Trade-offs and Advantages

No technology is a universal solution. The unique operating principle of induction furnaces presents a clear set of strengths and limitations.

Advantage: Superior Energy Efficiency

Very little energy is wasted heating the furnace structure or the surrounding air. Almost all the electrical power is converted directly into heat within the charge, making induction one of the most energy-efficient melting methods available.

Advantage: Cleanliness and Purity

The process produces no smoke, soot, or other byproducts of combustion. This cleanliness, combined with precise temperature control, allows for the creation of high-purity metals and alloys with an exact, repeatable composition.

Advantage: Operational Safety and Speed

Without open flames or massive external heat sources, the work environment is generally safer and cooler. The speed of melting also allows for higher throughput and more responsive production schedules.

Limitation: Conductive Materials Only

The fundamental physics of induction requires the charge material to be electrically conductive. Induction furnaces cannot be used to directly melt insulators like glass, ceramics, or polymers.

Making the Right Choice for Your Goal

Selecting the correct furnace technology depends entirely on the material you are processing and your desired outcome.

- If your primary focus is rapid, high-purity melting of metals: An induction furnace is the ideal choice for its unmatched speed, efficiency, and clean operation.

- If your primary focus is treating materials without surface oxidation: A vacuum furnace is necessary to control the atmosphere, regardless of which heating method is used inside.

- If your primary focus is processing non-conductive materials: A conventional resistance or fuel-fired furnace is required, as the principle of induction will not apply.

By leveraging electromagnetism, the induction furnace provides a powerful and precise tool for modern metallurgy.

Summary Table:

| Aspect | Induction Furnace | Conventional Furnace |

|---|---|---|

| Heating Method | Direct internal heating (via eddy currents) | Indirect heating (from external elements) |

| Energy Efficiency | High (heat generated within the metal) | Lower (heat loss to chamber and air) |

| Melting Speed | Very Fast | Slower |

| Material Suitability | Electrically conductive metals only | Conductive and non-conductive materials |

| Process Cleanliness | High (no combustion byproducts) | Varies (can produce fumes/soot) |

Ready to enhance your lab's metallurgy capabilities?

KINTEK specializes in high-performance lab equipment, including induction furnaces designed for rapid, precise, and clean metal melting. Our solutions help you achieve superior energy efficiency and material purity for your research and production goals.

Contact our experts today to find the perfect induction furnace for your laboratory's specific needs.

Visual Guide

Related Products

- Non Consumable Vacuum Arc Induction Melting Furnace

- Lab-Scale Vacuum Induction Melting Furnace

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is the primary function of vacuum melting equipment in Ti-Zr-Ni alloy preparation? Ensure Purity and Phase Stability

- What are the advantages and disadvantages of brazing? A Guide to Strong, Clean Metal Joining

- What is AC frame? Decoding the Two Meanings in Wi-Fi and Video

- What is the primary function of a vacuum arc melting furnace in RHEA preparation? Achieving Extreme Thermal Fusion

- What is the role of a laboratory vacuum arc remelting furnace? Mastering High-Entropy Alloy Synthesis