At its core, Physical Vapor Deposition (PVD) sputtering is a vacuum deposition method where atoms are physically ejected from a solid material, known as a target, and deposited onto an object, the substrate, to form a highly uniform thin film. The process works by creating a plasma from an inert gas, accelerating the resulting ions into the target with immense energy, and using this bombardment to dislodge, or "sputter," atoms from the target surface. These ejected atoms then travel across the vacuum chamber and condense on the substrate.

Sputtering is not a simple spraying or coating technique; it is an atomic-scale process of momentum transfer. Understanding this allows you to move beyond simply making a film and begin engineering its specific properties—from electrical resistivity and optical reflectivity to its very grain structure and density.

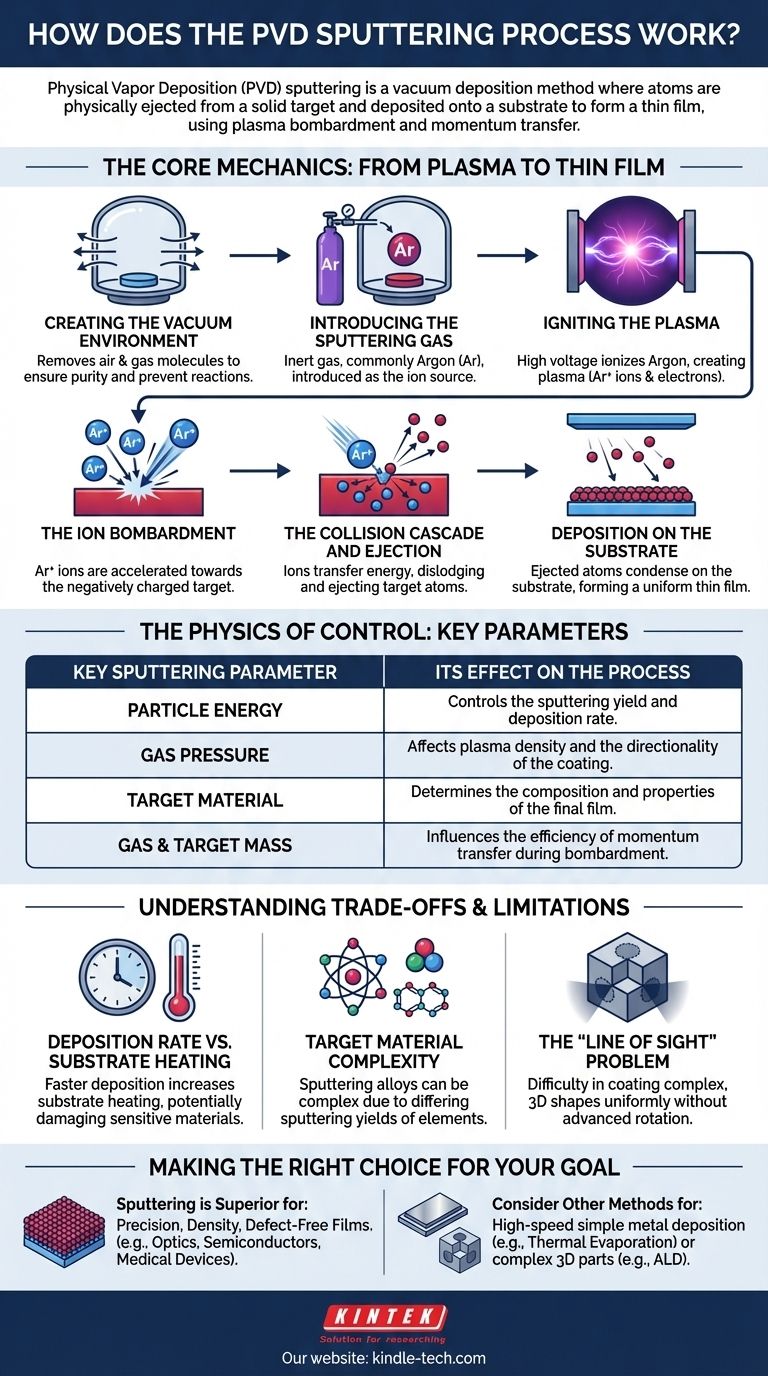

The Core Mechanics: From Plasma to Thin Film

To truly grasp sputtering, you must visualize it as a sequence of controlled physical events occurring inside a vacuum. Each step is critical for the final quality of the film.

Step 1: Creating the Vacuum Environment

The entire process happens in a vacuum chamber. This is non-negotiable.

The vacuum removes air and other gas molecules that could otherwise react with the sputtered atoms or physically impede their path to the substrate, ensuring the purity and integrity of the final film.

Step 2: Introducing the Sputtering Gas

Once a vacuum is established, a small, precisely controlled amount of an inert gas—most commonly Argon (Ar)—is introduced into the chamber.

This gas is not part of the final coating. Its sole purpose is to be the source of the ions that will bombard the target material.

Step 3: Igniting the Plasma

A high voltage is applied within the chamber, typically making the target material the negative electrode (cathode) and the substrate holder or chamber walls the positive electrode (anode).

This strong electric field energizes the Argon gas, stripping electrons from the Argon atoms. This creates a glowing, ionized gas known as a plasma, which is a volatile mix of positive Argon ions (Ar+) and free electrons.

Step 4: The Ion Bombardment

The positively charged Argon ions in the plasma are forcefully accelerated by the electric field, causing them to slam into the negatively charged target surface at high velocity.

Step 5: The Collision Cascade and Ejection

This is the "sputtering" event. An incoming ion does not simply chip off a single surface atom. Instead, it transfers its kinetic energy into the target, setting off a collision cascade beneath the surface, similar to a multi-ball break shot in billiards.

When this cascade of energized atoms reaches the surface with enough energy to overcome the material's atomic surface binding energy, one or more atoms are physically ejected into the vacuum.

Step 6: Deposition on the Substrate

The ejected atoms from the target travel through the vacuum chamber—largely in a straight line of sight—until they strike the substrate.

Upon arrival, these atoms condense on the cooler surface, gradually building up layer by layer to form a dense, uniform, and highly adherent thin film.

The Physics of Control: Key Sputtering Parameters

The quality and characteristics of the sputtered film are not left to chance. They are dictated by several key physical parameters that can be precisely controlled.

The Role of Particle Energy

The energy of the bombarding ions directly influences the sputtering yield—the number of target atoms ejected per incident ion. Higher energy generally results in a faster deposition rate.

The Influence of Mass

The efficiency of the momentum transfer depends on the relative masses of the sputtering gas ion and the target atom. Using a heavier inert gas, like Krypton or Xenon, can increase the sputtering yield for heavy target materials.

The Target's Binding Energy

Every material has a characteristic surface binding energy holding its atoms together. Materials with lower binding energies are easier to sputter, while those with very strong atomic bonds require more energy.

The Importance of Gas Pressure

The pressure of the sputtering gas inside the chamber is a critical control knob. It affects the density of the plasma and the "mean free path," or the average distance a sputtered atom can travel before hitting a gas molecule. Higher pressure can lead to more scattering and a less directional coating.

Understanding the Trade-offs and Limitations

While powerful, sputtering is not the universal solution for all coating needs. Acknowledging its trade-offs is key to using it effectively.

Deposition Rate vs. Substrate Heating

Sputtering is often a slower process compared to thermal evaporation. While increasing power and ion bombardment can speed up deposition, this also deposits significant energy into the substrate, which can cause unwanted heating and damage sensitive materials like plastics or electronics.

Target Material and Complexity

Sputtering a pure element is straightforward. However, sputtering a compound or an alloy can be complex, as the different elements may have different sputtering yields, potentially altering the composition of the deposited film compared to the target.

The "Line of Sight" Problem

In its most basic form, sputtering is a line-of-sight process. This makes it inherently difficult to uniformly coat complex, three-dimensional shapes with undercuts or hidden surfaces without incorporating sophisticated substrate rotation and tilting mechanisms.

Making the Right Choice for Your Goal

Your decision to use sputtering should be based on the specific requirements of your final product.

- If your primary focus is precision and density: Sputtering is the superior choice for creating exceptionally uniform, dense, and defect-free films with excellent adhesion, critical for high-performance optical coatings, semiconductors, and medical devices.

- If your primary focus is high-speed deposition of simple metals: A process like thermal evaporation might be a more cost-effective and faster solution for applications where film density and precise structural control are less critical.

- If your primary focus is perfectly uniform coating on complex 3D parts: You will either need to invest in a sputtering system with advanced planetary rotation or consider a non-line-of-sight process like Atomic Layer Deposition (ALD).

By understanding sputtering as a controllable physical phenomenon, you can engineer thin films with the exact properties your application demands.

Summary Table:

| Key Sputtering Parameter | Its Effect on the Process |

|---|---|

| Particle Energy | Controls the sputtering yield and deposition rate. |

| Gas Pressure | Affects plasma density and the directionality of the coating. |

| Target Material | Determines the composition and properties of the final film. |

| Gas & Target Mass | Influences the efficiency of momentum transfer during bombardment. |

Ready to engineer the perfect thin film for your application?

KINTEK specializes in high-performance lab equipment, including sputtering systems, to help you achieve precise, uniform coatings for semiconductors, optics, and medical devices. Our expertise ensures you get the density, adhesion, and control your research demands.

Contact our experts today to discuss your specific needs and find the ideal sputtering solution.

Visual Guide

Related Products

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- Evaporation Boat for Organic Matter

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Microwave Plasma Chemical Vapor Deposition MPCVD Machine System Reactor for Lab and Diamond Growth

People Also Ask

- What is the principle of plasma enhanced chemical vapor deposition? Achieve Low-Temperature Thin Film Deposition

- How are PECVD and CVD different? A Guide to Choosing the Right Thin-Film Deposition Process

- Why does PECVD commonly use RF power input? For Precise Low-Temperature Thin Film Deposition

- What are the applications of PECVD? Essential for Semiconductors, MEMS, and Solar Cells

- What is an example of PECVD? RF-PECVD for High-Quality Thin Film Deposition