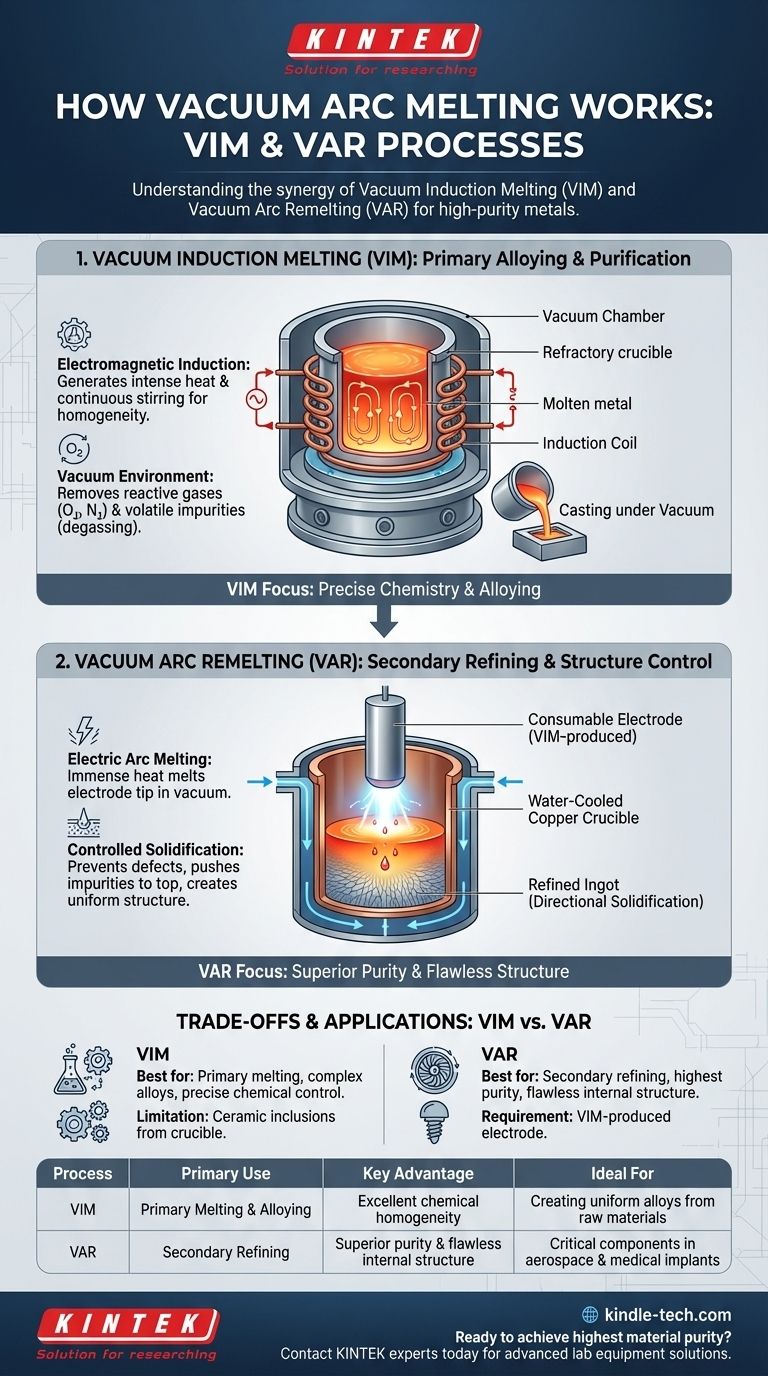

At its core, vacuum melting refers to several advanced metallurgical processes, with the most common being Vacuum Induction Melting (VIM) and Vacuum Arc Remelting (VAR). The term "vacuum arc melting" typically refers to VAR, but it's critical to understand VIM first, as it often precedes it. VIM uses electromagnetic induction to melt metals inside a vacuum chamber, which prevents contamination from atmospheric gases like oxygen and nitrogen and helps remove dissolved gas impurities from the melt.

While often conflated, Vacuum Induction Melting (VIM) and Vacuum Arc Remelting (VAR) are distinct but complementary processes. VIM is a primary melting method that uses electromagnetic fields for alloying and initial purification, whereas VAR is a secondary remelting process that uses an electric arc to achieve the highest levels of purity and structural integrity.

How Vacuum Induction Melting (VIM) Works

Vacuum Induction Melting is a versatile process for producing high-purity metals and alloys from raw materials. The entire operation takes place within a sealed, airtight chamber.

The Principle of Electromagnetic Induction

The process begins by placing solid metals into a refractory-lined crucible. This crucible is encircled by a water-cooled induction coil.

When a powerful alternating current is passed through this coil, it generates a fluctuating magnetic field. This field, in turn, induces strong electrical eddy currents within the metal charge itself.

The electrical resistance of the metal converts these eddy currents into intense heat, causing the material to heat up and eventually melt without any direct contact from a heat source.

The Role of the Vacuum

Performing this process under vacuum is fundamental. The vacuum environment removes air, preventing the highly reactive molten metal from oxidizing or picking up nitrogen.

Furthermore, the low-pressure environment facilitates the removal of dissolved gases (like hydrogen and oxygen) and volatile impurity elements from the molten bath, a process known as degassing.

The Furnace and Process

The furnace is a water-cooled, airtight vessel designed to withstand high vacuum levels. Inside, the induction coil and crucible form the heart of the system.

A key benefit of VIM is the electromagnetic stirring that naturally occurs. The same forces that heat the metal also create a continuous stirring action, ensuring excellent chemical homogeneity and uniform temperature throughout the melt.

Once the metal is melted, refined, and its chemistry adjusted, it is poured into molds, all while still under vacuum. This is often accomplished by tilting the entire crucible assembly.

Clarifying the "Arc": Vacuum Arc Remelting (VAR)

While VIM is a primary melting process, Vacuum Arc Remelting (VAR) is a secondary refining process used to create metals with exceptionally high purity and an ideal internal structure. This is the process most accurately described as "vacuum arc melting."

The Consumable Electrode

VAR does not start with raw metal chunks. Instead, it begins with a solid, cylindrical ingot of the desired alloy, which is called a consumable electrode. This electrode is very often produced first using the VIM process.

The Electric Arc

This electrode is suspended inside a water-cooled copper crucible within a vacuum chamber. A DC electric arc is initiated between the bottom tip of the electrode and a small amount of starter metal at the base of the crucible.

The immense heat from the arc (reaching thousands of degrees) progressively melts the tip of the electrode.

Controlled Solidification

As the electrode's tip melts, droplets of purified metal fall into the water-cooled copper mold below. Solidification occurs directionally, from the bottom up, in a highly controlled manner.

This slow, controlled solidification helps to push non-metallic inclusions and impurities to the top of the new ingot, which can be cropped off later. It also produces a dense, uniform grain structure that is free of defects like shrinkage and porosity.

Understanding the Trade-offs: VIM vs. VAR

These two processes are not competitors; they are partners in the production of high-performance materials for critical applications.

VIM: Ideal for Alloying and Homogeneity

VIM's strength lies in its ability to melt a complex charge of raw materials and create a precise, chemically uniform alloy. The electromagnetic stirring is unparalleled for mixing alloying elements.

However, contact with the refractory crucible can introduce microscopic ceramic inclusions, limiting the ultimate level of cleanliness.

VAR: Superior for Purity and Structure

VAR's strength is its ability to refine an already-formed alloy to the highest possible purity. Because it uses a water-cooled copper crucible, there is no refractory contact, eliminating that source of contamination.

The controlled, directional solidification heals internal defects and produces a superior, highly consistent microstructure essential for demanding applications like aerospace turbine disks or biomedical implants.

Making the Right Choice for Your Goal

Your choice of process depends entirely on the final material requirements.

- If your primary focus is creating a homogenous, high-quality alloy from raw materials: VIM is the definitive process for primary melting and precise chemistry control.

- If your primary focus is achieving the absolute highest purity and a flawless internal structure for a critical component: VAR is the necessary secondary step, using a VIM-produced electrode as its starting material.

Ultimately, these vacuum melting technologies provide engineers with precise control over a material's chemistry and structure, enabling the creation of alloys that can perform under the most extreme conditions.

Summary Table:

| Process | Primary Use | Key Advantage | Ideal For |

|---|---|---|---|

| VIM | Primary Melting & Alloying | Excellent chemical homogeneity & precise chemistry control | Creating uniform alloys from raw materials |

| VAR | Secondary Refining | Superior purity & flawless internal structure | Critical components in aerospace and medical implants |

Ready to achieve the highest material purity for your critical applications?

KINTEK specializes in advanced lab equipment, including systems for high-purity metal production. Whether you are developing aerospace components, biomedical implants, or next-generation alloys, our expertise can help you optimize your melting and refining processes.

Contact our experts today to discuss how our solutions can enhance your material quality and performance.

Visual Guide

Related Products

- Vacuum Arc Induction Melting Furnace

- Vacuum Induction Melting Spinning System Arc Melting Furnace

- Vacuum Heat Treat Sintering Brazing Furnace

- Lab-Scale Vacuum Induction Melting Furnace

- Vacuum Heat Treat Furnace and Levitation Induction Melting Furnace

People Also Ask

- What is the remelting process? Achieve Ultimate Purity and Performance for High-Strength Alloys

- What is the VAR melting process? The Ultimate Guide to Vacuum Arc Remelting

- What is var in metals? A Guide to Vacuum Arc Remelting for Superior Alloys

- What is the benefit of vacuum arc remelting? Achieve Superior Metal Purity and Structural Integrity

- What is a remelting process? A Guide to High-Purity Metal Refinement