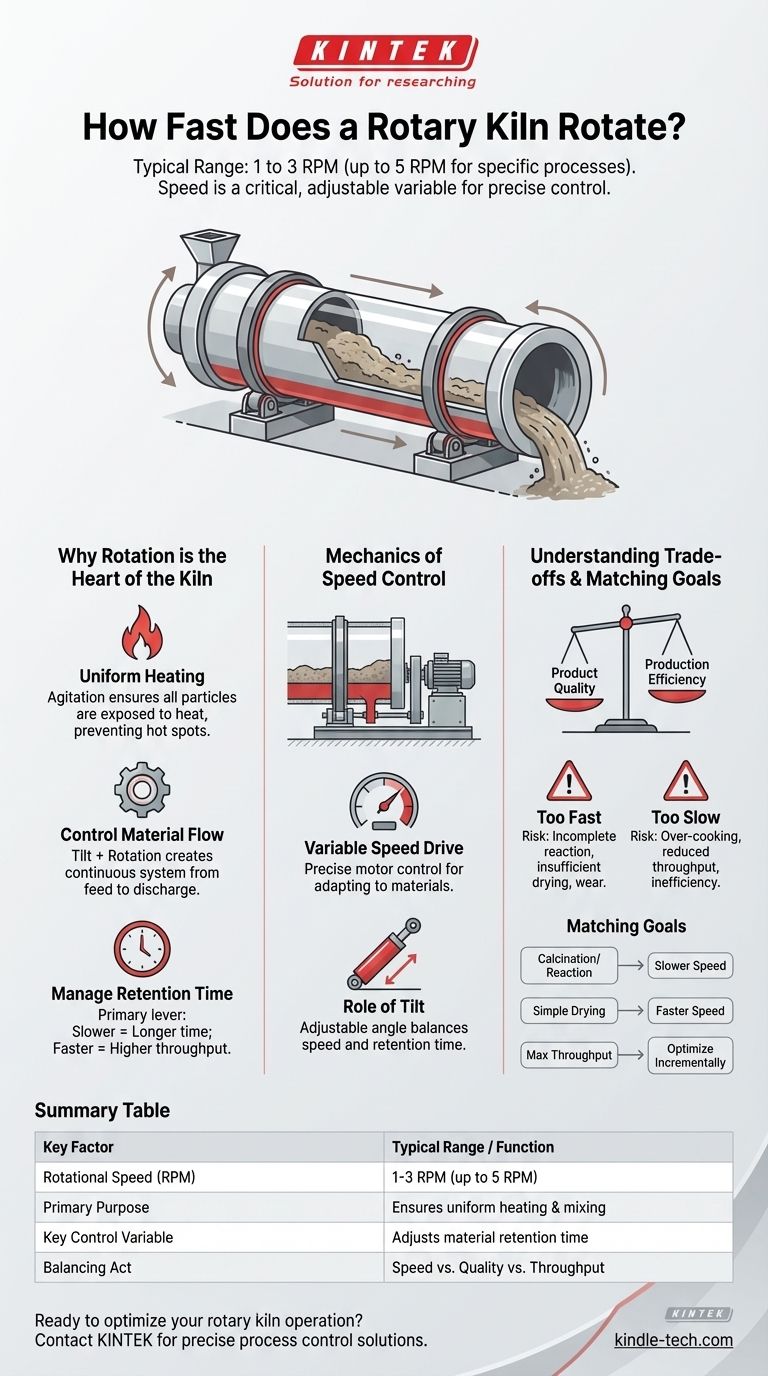

In most industrial applications, a rotary kiln rotates at a slow and deliberate pace of 1 to 3 revolutions per minute (RPM). While this is the typical range, some specific processes may require speeds as fast as 5 RPM to achieve the desired result.

The rotational speed of a rotary kiln is not a fixed number but a critical, adjustable process variable. This speed is intentionally slow to precisely control how long material is heated, ensuring it undergoes a complete and uniform transformation.

Why Rotation is the Heart of the Kiln

A rotary kiln is essentially a large, rotating cylinder designed to process materials at extremely high temperatures. The rotation itself is fundamental to its function, serving several key purposes.

To Ensure Uniform Heating

The primary goal of the kiln is to heat every particle of a material equally. The slow tumbling action caused by rotation continuously mixes the material bed.

This process, known as agitation, ensures that all surfaces of the material are exposed to the heat source, preventing hot spots and guaranteeing a consistent final product.

To Control Material Flow

Rotary kilns are set at a slight horizontal angle. This tilt, combined with the rotation, gently coaxes material from the feed end to the discharge end.

This mechanism creates a continuous processing system, allowing raw material to be fed in one end and the finished product to be discharged from the other without interruption.

To Manage Retention Time

Retention time is the amount of time the material spends inside the kiln. The rotational speed is the primary lever for controlling this.

A slower rotation means a longer retention time, giving the material more time to dry, react, or calcine. A faster rotation shortens this time, increasing the rate of production (throughput).

The Mechanics of Speed Control

The ability to fine-tune the rotational speed is what makes the rotary kiln such a versatile and precise piece of industrial equipment.

The Variable Speed Drive

Modern kilns are equipped with a variable speed electric motor as part of the drive assembly. This allows operators to easily adjust the RPM.

This precise control is essential for adapting the kiln's operation to different materials or for changing process requirements on the fly.

The Role of Tilt

In addition to speed, the tilt angle of the kiln can also be adjusted, often with a hydraulic system.

Increasing the slope will cause material to move through faster, while a shallower angle will increase retention time. The optimal process uses a careful balance of both rotational speed and tilt angle.

Understanding the Trade-offs

Selecting the correct rotational speed is a balancing act between product quality and production efficiency. There are clear risks associated with getting it wrong.

The Danger of Rotating Too Fast

If the kiln rotates too quickly, the material may not have sufficient retention time to undergo the required physical or chemical change.

This can result in an incomplete reaction, insufficient drying, or a low-quality final product. It also increases wear on the machinery and can create excessive dust.

The Inefficiency of Rotating Too Slow

While a slow speed ensures thorough processing, an unnecessarily slow rotation can damage the product by over-cooking or burning it.

Furthermore, it directly reduces the kiln's throughput, making the entire operation less efficient and more costly. The goal is to find the fastest possible speed that still guarantees the desired product quality.

Matching Kiln Speed to Your Processing Goal

The ideal rotational speed is dictated entirely by the material being processed and the desired outcome.

- If your primary focus is complete calcination or complex chemical reactions: You will need a slower speed to maximize retention time and ensure the reaction is fully completed.

- If your primary focus is simple drying of a robust material: A slightly faster speed can be used to increase plant throughput without compromising the final quality.

- If your primary focus is maximizing throughput for any process: The optimal approach is to start slow and incrementally increase the speed, performing quality checks at each stage to find the highest possible RPM that still yields an acceptable product.

Ultimately, mastering the rotational speed is the key to unlocking the full efficiency and precision of your rotary kiln operation.

Summary Table:

| Key Factor | Typical Range / Function |

|---|---|

| Rotational Speed (RPM) | 1 to 3 RPM (up to 5 RPM for some processes) |

| Primary Purpose | Ensures uniform heating and mixing of materials |

| Key Control Variable | Adjusts material retention time inside the kiln |

| Balancing Act | Speed vs. Product Quality vs. Production Throughput |

Ready to optimize your rotary kiln operation for peak performance and product quality?

At KINTEK, we specialize in providing robust laboratory equipment and consumables for precise process control and material testing. Whether you're developing a new process or fine-tuning an existing one, our solutions can help you determine the perfect rotational speed and operating parameters for your specific materials.

Contact our experts today to discuss how KINTEK can support your laboratory and processing needs.

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Electric Rotary Kiln Small Rotary Furnace for Activated Carbon Regeneration

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Three-dimensional electromagnetic sieving instrument

People Also Ask

- What role does a high-temperature rotary kiln play in the production of cement clinker? Mastering Sintering Efficiency

- What is the technique of pyrolysis? A Guide to Thermal Decomposition Without Oxygen

- What is the process of carbon regeneration? Restore Spent Carbon for Cost-Effective, Sustainable Use

- What is microwave pyrolysis of polypropylene? An Advanced Chemical Recycling Method

- What is the residence time of microwave pyrolysis? Achieve Fast, Efficient Biomass Conversion

- What is the main function of rotary kiln? Powering Industrial Processes with High-Temperature Precision

- What are the hazards of plastic pyrolysis? Understanding the Environmental and Safety Risks

- How do you calculate the cost of firing an electric kiln? Master Your Studio's Energy Expenses