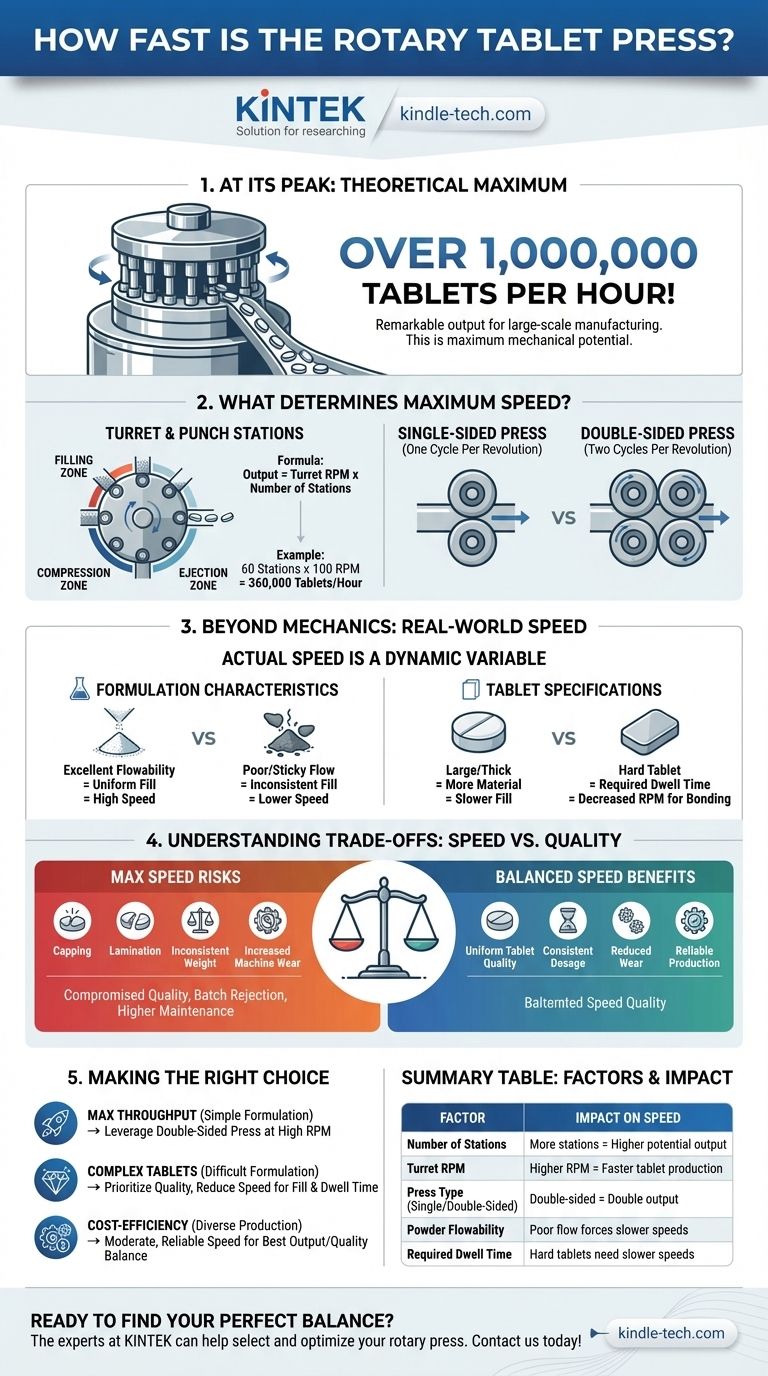

At its peak, a high-speed rotary tablet press is capable of producing well over 1,000,000 tablets per hour. This remarkable output is a primary reason for its adoption in large-scale manufacturing. However, this figure represents the machine's maximum mechanical potential, not the practical speed for every application.

The true production speed of a rotary tablet press is not a fixed number. It is a dynamic variable determined by the machine's design, the number of stations, and most critically, the physical characteristics of the powder being compressed and the quality requirements of the final tablet.

What Determines the Maximum Speed?

The high output of a rotary tablet press comes from its core design principle: parallel processing. Instead of a single station, it uses a rotating turret fitted with multiple sets of punches and dies.

The Role of the Turret and Punch Stations

The heart of the machine is the turret, which holds numerous punch stations. Each station is a complete system for producing one tablet. As the turret rotates, each station passes sequentially through the filling, compression, and ejection zones.

The total output is a direct function of the turret's rotational speed and the number of stations. A press with 60 stations running at 100 revolutions per minute (RPM) will have a theoretical output of 6,000 tablets per minute (360,000 per hour).

Single-Sided vs. Double-Sided Presses

A single-sided rotary press has one filling station and one set of compression rollers. The entire process of filling, compressing, and ejecting happens once per revolution for each station.

High-output machines are often double-sided. They feature two separate filling stations and two sets of compression rollers on opposite sides of the turret. This design effectively doubles the output for the same rotational speed, enabling the highest production rates.

Beyond Mechanics: Why Real-World Speed Varies

Achieving the maximum theoretical speed is rare in practice. The actual, sustainable production rate is almost always lower, dictated by the interplay between the powder formulation and the desired tablet quality.

Formulation Characteristics

The single most important factor is the powder itself. A formulation with excellent flowability will fill the die cavities uniformly and quickly, even at high speeds.

Poorly flowing or "sticky" powders require more time to fill the dies properly. Running the press too fast with such materials will result in inconsistent tablet weights and rejected batches, forcing the operator to reduce the speed.

Tablet Specifications

The physical requirements of the tablet also limit speed. A large, thick tablet requires more material to fill the die.

Furthermore, creating a very hard tablet requires sufficient dwell time—the duration the punches remain under maximum pressure. To increase dwell time and ensure proper bonding, the turret's rotation speed must often be decreased.

Understanding the Trade-offs: Speed vs. Quality

Pushing a rotary press to its maximum speed without considering other factors inevitably compromises tablet quality. This is the central trade-off in tablet manufacturing.

The Risk of Capping and Lamination

At very high speeds, air can be entrapped within the powder in the die cavity. During compression, this trapped air can cause the top of the tablet to break off (capping) or the body to split into layers (lamination). These are critical defects that lead to batch rejection.

Inconsistent Weight and Dosage

Precise control over the tablet weight is fundamental, especially in pharmaceuticals. If the press runs faster than the powder can consistently fill each die, tablet weights will vary. This leads to inconsistent dosage and is a major quality failure.

Increased Machine Wear

Operating a press at its absolute maximum speed for extended periods significantly increases wear on the tooling (punches and dies) and other mechanical components. This results in more frequent maintenance, downtime, and higher long-term operational costs, which can offset the benefits of the higher output.

Making the Right Choice for Your Goal

The "speed" of a rotary press is not one number but a range of possibilities. Your operational goal dictates the optimal point within that range.

- If your primary focus is maximum throughput for a simple, highly-flowable formulation: You can leverage a double-sided press at high RPM to approach the machine's top-rated speed.

- If your primary focus is producing a complex or difficult-to-compress tablet: You must prioritize quality and consistency by reducing the speed to ensure proper die filling and adequate dwell time.

- If your primary focus is cost-efficiency for diverse or smaller-scale production: The independent control over tablet parameters on a rotary press provides flexibility, but running at a moderate, reliable speed will yield the best balance of output and quality.

Ultimately, the optimal speed of a rotary tablet press is the rate that consistently and efficiently delivers high-quality tablets for your specific product.

Summary Table:

| Factor | Impact on Speed |

|---|---|

| Number of Stations | More stations = higher potential output per rotation. |

| Turret RPM | Higher RPM = faster tablet production. |

| Press Type (Single/Double-Sided) | Double-sided presses can double output at the same RPM. |

| Powder Flowability | Poor flow forces slower speeds to ensure consistent fill. |

| Required Dwell Time | Hard tablets need slower speeds for proper compression. |

Ready to find the perfect balance of speed and quality for your tablet production? The experts at KINTEK can help you select and optimize a rotary press for your specific formulation and output goals. Contact us today to discuss your lab's equipment needs!

Visual Guide

Related Products

- Single Punch Tablet Press Machine and Mass Production Rotary Tablet Punching Machine for TDP

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Single Punch Electric Tablet Press Machine TDP Tablet Punching Machine

- Lab Scale Rotary Single Punch Tablet Press Machine TDP Tablet Punching Machine

- Single Punch Manual Tablet Press Machine TDP Tablet Punching Machine

People Also Ask

- What is a punch tablet press? Precision Tableting for R&D and Small Batches

- What is the difference between single punch and rotary tablet press? Choose the Right Machine for Your Lab or Production

- What are pill presses used for? Transforming Powders into Precise Tablets for Medicine, Supplements, and More

- What is the function of a tablet press? Transforming Powder into Precise, Uniform Tablets

- What are the two classifications of press machines? Single Punch vs. Rotary Presses Explained

- How does a mechanical pelletizer extend the life of calcium-based adsorbents? Maximize Your Adsorbent Durability

- What are the different parts of a single punch tablet machine? The Core Components Explained

- What are advantages of single punch tablet press machine? Maximize R&D Efficiency with Minimal Material