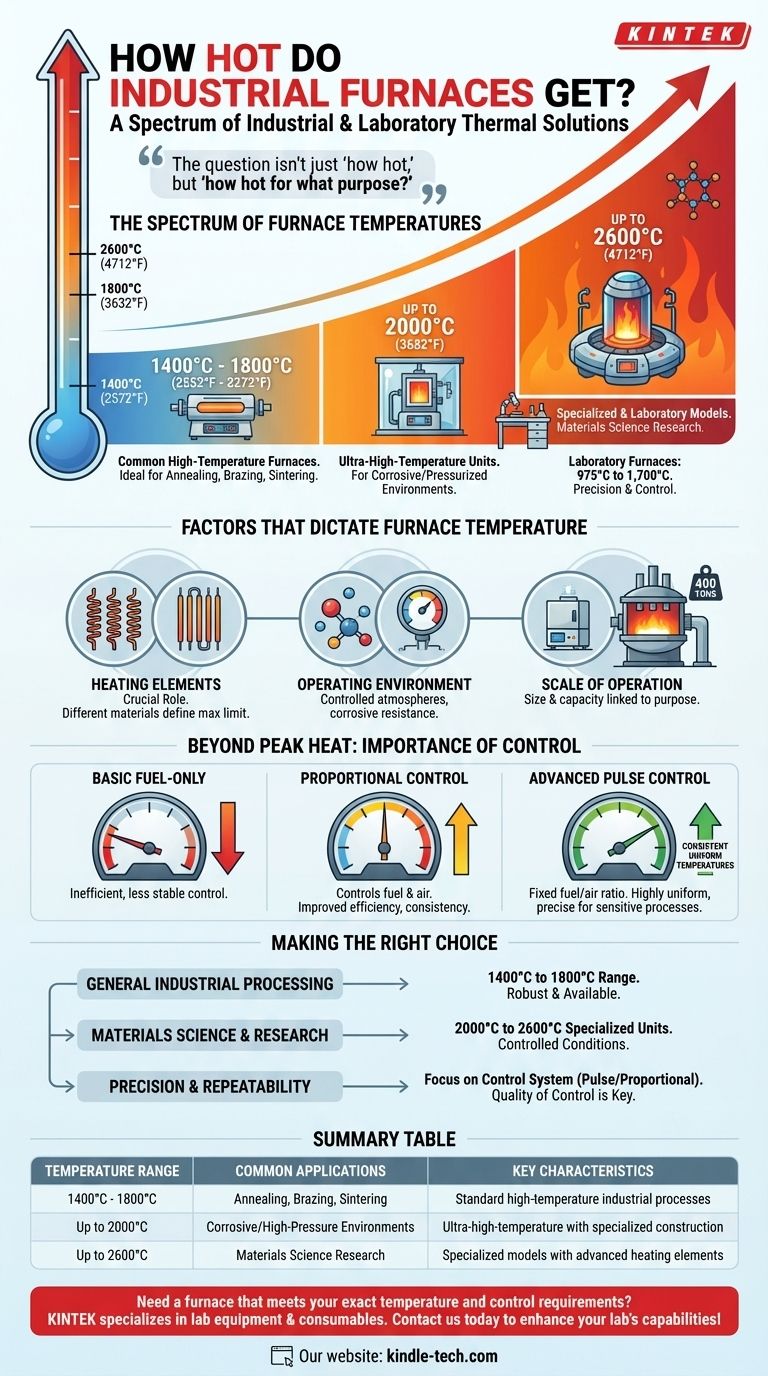

The maximum temperature of an industrial furnace varies significantly based on its design and purpose, with some specialized models reaching up to 2600°C (4712°F). More commonly, high-temperature industrial furnaces operate in the range of 1400°C to 1800°C, while ultra-high-temperature units are designed to sustain up to 2000°C even in corrosive or pressurized environments.

The question isn't just "how hot," but "how hot for what purpose?" An industrial furnace's temperature capability is a direct reflection of its specific application, from large-scale metal melting to precise laboratory experiments.

The Spectrum of Furnace Temperatures

Industrial furnaces are not a single category but a broad range of equipment, each engineered for a specific thermal task. Their operating temperatures reflect this diversity.

Common High-Temperature Furnaces

Most standard high-temperature furnaces, including many tube furnace models, are designed to operate reliably between 1400°C and 1800°C (2552°F - 3272°F). This range is sufficient for a vast array of industrial processes like annealing, brazing, and sintering.

Ultra-High-Temperature Furnaces

For more demanding applications, ultra-high-temperature furnaces can consistently reach 2000°C (3632°F). These units are built to withstand harsh conditions, including corrosive atmospheres and positive pressure environments.

Specialized and Laboratory Models

At the highest end, certain specialized tube furnaces can achieve temperatures up to 2600°C (4712°F). This capability depends heavily on the type of heating elements used in their construction.

In contrast, laboratory furnaces are built for precision and control, typically operating at a maximum of 975°C to 1,700°C.

Factors That Dictate Furnace Temperature

A furnace's maximum temperature is not an arbitrary number. It is the result of specific engineering decisions driven by the intended application and required performance.

The Critical Role of Heating Elements

The single most important factor is the type of heating element used. Different materials have different maximum operating temperatures, and choosing the right element is fundamental to furnace design.

The Operating Environment

Furnaces must also be built to handle their internal environment. The ability to maintain extreme heat in a controlled atmosphere—or a corrosive one—requires specialized construction and materials beyond the heating elements alone.

Scale of Operation

The furnace's size and capacity are linked to its purpose. A small laboratory unit has different design constraints than a massive industrial arc furnace capable of handling 400 tons of material.

Beyond Peak Heat: The Importance of Control

Reaching a high temperature is only half the battle. Maintaining that temperature with precision and efficiency is what makes a furnace effective and economical.

Basic Fuel-Only Systems

The simplest systems control only the flow of fuel. While inexpensive to implement, they are often inefficient and provide less stable temperature control.

Proportional Control Systems

A significant improvement, proportional systems control both the fuel and air supply. This improves fuel efficiency, lowers operating costs, and allows for more consistent temperature regulation.

Advanced Pulse Control

Pulse control systems maintain a fixed fuel-to-air ratio while using high flame velocity. This ensures highly consistent and uniform temperatures throughout the furnace chamber, which is critical for sensitive industrial processes.

Making the Right Choice for Your Application

Selecting a furnace requires matching its capabilities to your specific thermal processing needs.

- If your primary focus is general industrial processing: Furnaces operating in the 1400°C to 1800°C range offer a robust and widely available solution.

- If your primary focus is materials science or cutting-edge research: You may require a specialized furnace capable of reaching 2000°C to 2600°C under controlled conditions.

- If your primary focus is precision and repeatability: The quality of the temperature control system (such as pulse or proportional control) is just as important as the maximum temperature.

Ultimately, understanding the right thermal technology for the job is the key to achieving your desired outcome.

Summary Table:

| Temperature Range | Common Applications | Key Characteristics |

|---|---|---|

| 1400°C - 1800°C | Annealing, Brazing, Sintering | Standard high-temperature industrial processes |

| Up to 2000°C | Corrosive/High-Pressure Environments | Ultra-high-temperature with specialized construction |

| Up to 2600°C | Materials Science Research | Specialized models with advanced heating elements |

Need a furnace that meets your exact temperature and control requirements? KINTEK specializes in lab equipment and consumables, providing industrial and laboratory furnaces with precise temperature control up to 2600°C. Our expertise ensures you get the right thermal technology for processes like annealing, sintering, or advanced materials research. Contact us today to discuss your specific needs and enhance your lab's capabilities!

Visual Guide

Related Products

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- Molybdenum Vacuum Heat Treat Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

- 2200 ℃ Tungsten Vacuum Heat Treat and Sintering Furnace

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

People Also Ask

- What are the advantages of a tube furnace? Achieve Superior Temperature Uniformity and Control

- What is the ceramic tube high temperature? From 1100°C to 1800°C, Choose the Right Material

- How to clean a tube furnace? A Step-by-Step Guide for Safe and Effective Maintenance

- What tube is used for tubular furnace? Choose the Right Material for Temperature & Atmosphere

- What are the advantages of using an alumina liner in a tube furnace for biomass combustion corrosion simulations?