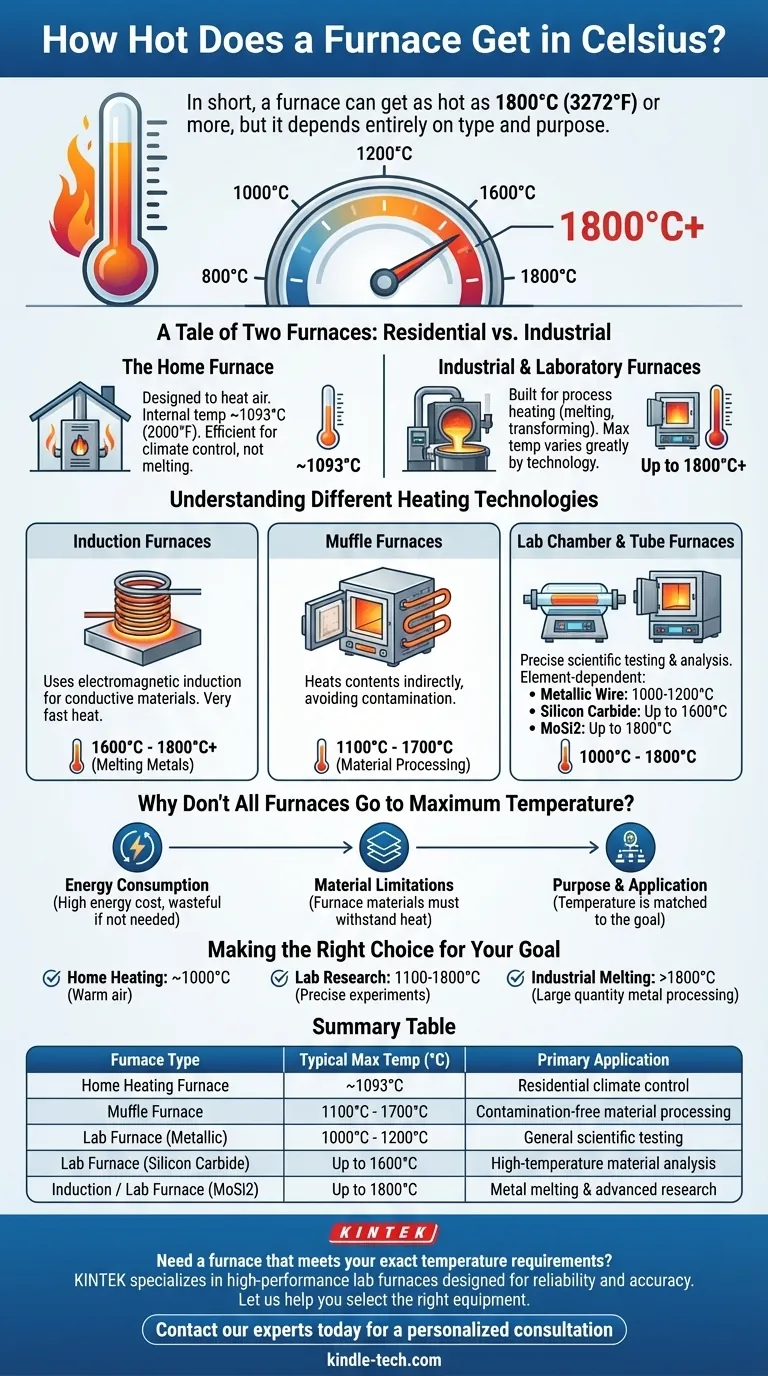

In short, a furnace can get as hot as 1800°C (3272°F) or more, but the specific temperature depends entirely on its type and purpose. A standard natural gas furnace for home heating operates around 1093°C, while specialized industrial furnaces designed for melting metals can reach significantly higher temperatures.

The term "furnace" covers a vast range of equipment, from simple home heating units to powerful industrial machines. The critical factor determining its maximum temperature is its heating technology and its intended application, whether it's warming air, conducting scientific experiments, or melting steel.

A Tale of Two Furnaces: Residential vs. Industrial

The most common source of confusion is the difference between the furnace in a home and those used in professional settings. They are fundamentally different tools designed for different jobs.

The Home Furnace

A residential forced-air furnace, typically running on natural gas, is designed to heat air. The internal temperature within the heat exchanger can reach approximately 1093°C (2000°F).

This high heat is used to quickly warm the air that is then circulated throughout your house. The furnace is not designed to melt materials, but rather to operate efficiently and safely for climate control.

Industrial & Laboratory Furnaces

Industrial and lab furnaces are built for process heating—transforming materials through high temperatures. Their capabilities are defined by their specific heating mechanism and can vary dramatically.

Understanding Different Heating Technologies

The technology used to generate heat is the primary driver of a furnace's maximum temperature.

Induction Furnaces

Induction furnaces use electromagnetic induction to heat conductive materials like metal. By creating powerful eddy currents within the material itself, they can generate intense heat very quickly.

Depending on the design and power, these furnaces can reach temperatures of 1600°C to over 1800°C (2900°F to 3272°F), making them ideal for melting and alloying metals.

Muffle Furnaces

A muffle furnace heats its contents indirectly. The material is placed inside a "muffle"—a high-temperature chamber—which is then heated from the outside. This prevents the material from being contaminated by fuel or combustion byproducts.

Their maximum temperatures vary by model but can range from 1100°C to 1700°C (2012°F to 3092°F).

Laboratory Chamber & Tube Furnaces

These furnaces are used for precise scientific testing and material analysis. Their maximum temperature is determined by the material used for the heating elements.

- Metallic Wire Elements: Typically achieve 1000°C to 1200°C.

- Silicon Carbide Elements: Can reach up to 1600°C.

- Molybdenum Disilicide Elements: Achieve the highest temperatures, up to 1800°C.

Rotary tube furnaces, another lab variant, are often used for continuous processing and typically operate up to 1000°C.

Why Don't All Furnaces Go to Maximum Temperature?

There are critical trade-offs that dictate a furnace's temperature limits. Higher heat is not always better and comes with significant engineering and financial costs.

Energy Consumption

Reaching and maintaining extremely high temperatures requires a massive amount of energy. A furnace is designed to be as energy-efficient as possible for its specific task. Over-engineering for unnecessary heat would be incredibly wasteful.

Material Limitations

The furnace itself must be constructed from materials that can withstand its own internal heat. The heating elements, insulation, and structural chamber must all remain stable at the target operating temperature. This is a primary constraint on furnace design.

Purpose and Application

The temperature is matched to the goal. A home furnace doesn't need to melt steel; it just needs to heat air. A laboratory furnace doesn't need to melt tons of scrap metal; it needs to hold a precise temperature for a small sample.

Making the Right Choice for Your Goal

The "right" temperature is entirely dependent on what you need to accomplish.

- If your primary focus is home heating: You are dealing with a natural gas furnace that operates internally around 1000°C to warm the air in your home.

- If your primary focus is laboratory research: Your required temperature will range from 1100°C to 1800°C, depending on the specific heating element technology needed for your experiment.

- If your primary focus is industrial melting: You need a high-power induction furnace capable of exceeding 1800°C to efficiently process large quantities of metal.

Ultimately, a furnace's temperature is a direct function of its design, technology, and purpose.

Summary Table:

| Furnace Type | Typical Maximum Temperature (°C) | Primary Application |

|---|---|---|

| Home Heating Furnace | ~1093°C | Residential climate control |

| Muffle Furnace | 1100°C - 1700°C | Contamination-free material processing |

| Lab Furnace (Metallic) | 1000°C - 1200°C | General scientific testing |

| Lab Furnace (Silicon Carbide) | Up to 1600°C | High-temperature material analysis |

| Induction / Lab Furnace (MoSi2) | Up to 1800°C | Metal melting & advanced research |

Need a furnace that meets your exact temperature requirements?

Whether your lab work demands precise heating up to 1100°C or advanced material processing at 1800°C, KINTEK has the solution. We specialize in high-performance lab furnaces, including chamber, tube, and muffle furnaces, designed for reliability and accuracy.

Let us help you select the right equipment for your specific application.

Contact our experts today for a personalized consultation and discover how KINTEK's lab equipment can enhance your research and productivity.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1800℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1400℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- How is heat transferred in a furnace? Master Radiation, Convection & Conduction

- How is the ash content determined in a muffle furnace? Master the Gravimetric Analysis Method

- What construction features contribute to the practicality and reliability of a muffle furnace? Key Design Elements for Lab Success

- What is the debinding process? A Guide to Critical Binder Removal for MIM & 3D Printing

- What is melt loss? The Ultimate Guide to Reducing Metal Loss in High-Temp Processing