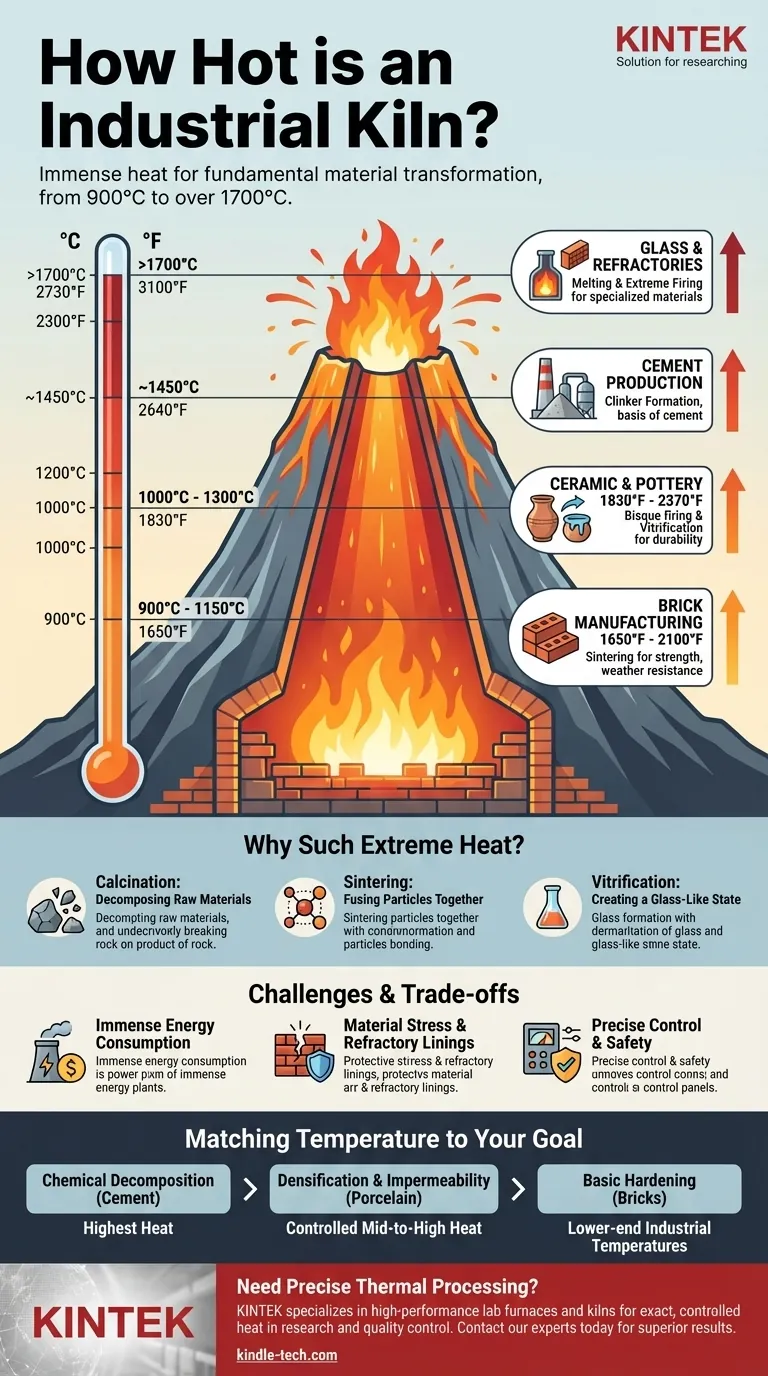

An industrial kiln's temperature is immense, operating across a vast range from around 900°C (1650°F) for common building materials to over 1700°C (3100°F) for specialized industrial refractories. The specific temperature is not a matter of simply "getting it hot," but a precisely controlled variable dictated entirely by the raw materials being processed and the desired chemical transformation.

The core purpose of an industrial kiln is to use extreme, targeted heat to fundamentally alter the chemical and physical structure of materials. The temperature isn't just a setting; it's the primary tool for turning raw earth into cement, clay into durable ceramics, and sand into glass.

Why Such Extreme Heat? The Science of Transformation

The staggering temperatures inside a kiln are necessary to initiate irreversible changes at a molecular level. Think of it less like a kitchen oven and more like a controlled volcano, engineered to achieve specific material outcomes.

Calcination: Decomposing Raw Materials

At very high temperatures, raw materials like limestone chemically decompose. In cement production, this process, called calcination, occurs around 900°C and is essential for driving off carbon dioxide to create lime, a critical ingredient for the final product.

Sintering: Fusing Particles Together

Sintering is the process of using heat to fuse particles together into a solid, dense mass without melting them completely. This is the fundamental principle behind firing ceramics and pottery, creating strength and durability from what was once soft clay.

Vitrification: Creating a Glass-Like State

At even higher temperatures, materials can vitrify, meaning they begin to turn into a non-crystalline, glass-like substance. This process creates an impermeable, hardened surface, which is essential for products like porcelain, certain tiles, and glazes.

A Spectrum of Heat: Kiln Temperatures by Application

Different industries require vastly different thermal conditions to create their products. The temperature profile is carefully managed to ensure the correct transformation occurs.

Cement Production (~1450°C / 2640°F)

Rotary cement kilns are among the hottest. After the initial calcination, the material temperature is raised to approximately 1450°C (2640°F) to form the clinker, the synthetic rock that is the basis of all modern cement.

Ceramic and Pottery Firing (~1000°C - 1300°C / 1830°F - 2370°F)

The ceramics industry uses a wide range of temperatures. An initial "bisque" firing to harden the clay occurs around 1000°C (1830°F), while a final glaze firing for durable stoneware or porcelain can reach up to 1300°C (2370°F) to achieve vitrification.

Brick Manufacturing (~900°C - 1150°C / 1650°F - 2100°F)

Producing common building bricks requires less intense heat. Firing temperatures typically fall between 900°C and 1150°C, which is sufficient to create a hard, weather-resistant final product through sintering.

Glass and Refractory Materials (>1500°C / 2730°F)

Industrial furnaces for melting glass (a process analogous to a kiln) operate above 1500°C (2730°F). Furthermore, the very materials used to line these kilns, known as refractories, must themselves be fired at extreme temperatures often exceeding 1700°C (3100°F) to withstand their service environment.

Understanding the Trade-offs and Challenges

Operating at these temperatures introduces significant engineering and economic challenges. The choice of temperature is always a balance between material requirements and operational reality.

Immense Energy Consumption

Maintaining kiln temperatures requires a colossal amount of energy, making it one of the largest operational costs in heavy industry. Efficiency and heat recovery are paramount concerns for any plant manager.

Material Stress and Refractory Linings

The kiln itself must be constructed from materials that can withstand its internal environment. This requires specialized refractory bricks and linings that are both insulating and structurally stable at temperatures that would melt steel. The lifespan of this lining is a critical operational factor.

Precise Control and Safety

Temperature must be controlled with incredible precision. A deviation of just a few degrees can ruin an entire batch of product. The extreme heat also presents significant safety risks, requiring rigorous protocols and specialized equipment to protect personnel.

Matching Temperature to Your Material Goal

The correct temperature is determined by the end goal for the material. Understanding this relationship is key to understanding industrial processing.

- If your primary focus is chemical decomposition (e.g., cement): You require the highest heat levels to drive reactions like calcination and form new chemical compounds.

- If your primary focus is densification and impermeability (e.g., porcelain): You need carefully controlled mid-to-high range temperatures to achieve full vitrification without deforming the product.

- If your primary focus is basic hardening and strength (e.g., bricks): Lower-end industrial temperatures are sufficient for sintering and are far more energy-efficient for mass production.

Ultimately, the temperature inside an industrial kiln is a direct reflection of the ambition to transform raw matter into the foundational materials of our world.

Summary Table:

| Application | Typical Temperature Range | Key Process |

|---|---|---|

| Cement Production | ~1450°C (2640°F) | Clinker Formation |

| Ceramics & Pottery | 1000°C - 1300°C (1830°F - 2370°F) | Vitrification |

| Brick Manufacturing | 900°C - 1150°C (1650°F - 2100°F) | Sintering |

| Glass & Refractories | >1500°C (2730°F) | Melting / High-Temp Firing |

Need precise thermal processing for your materials? The correct temperature is critical for achieving the desired chemical and physical transformation in your products. KINTEK specializes in high-performance lab furnaces and kilns that deliver the exact, controlled heat required for research, development, and quality control in cement, ceramic, and material science industries. Contact our thermal experts today to discuss how our equipment can help you achieve superior results.

Visual Guide

Related Products

- Electric Rotary Kiln Pyrolysis Furnace Plant Machine Calciner Small Rotary Kiln Rotating Furnace

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Vacuum Sealed Continuous Working Rotary Tube Furnace Rotating Tube Furnace

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

- Engineering Advanced Fine Ceramics Head Tweezers with Pointed Elbow Zirconia Ceramic Tip

People Also Ask

- What are the products of pyrolysis of wood? A Guide to Biochar, Bio-oil, and Syngas Yields

- What are the industrial applications of pyrolysis? Transform Waste into Energy and Valuable Products

- What equipment is used in pyrolysis? Choosing the Right Reactor for Your Feedstock and Products

- What are the zones in rotary kiln in cement production? Master the Core Process for High-Quality Clinker

- What is the difference between calcining and roasting? A Guide to High-Temperature Processing