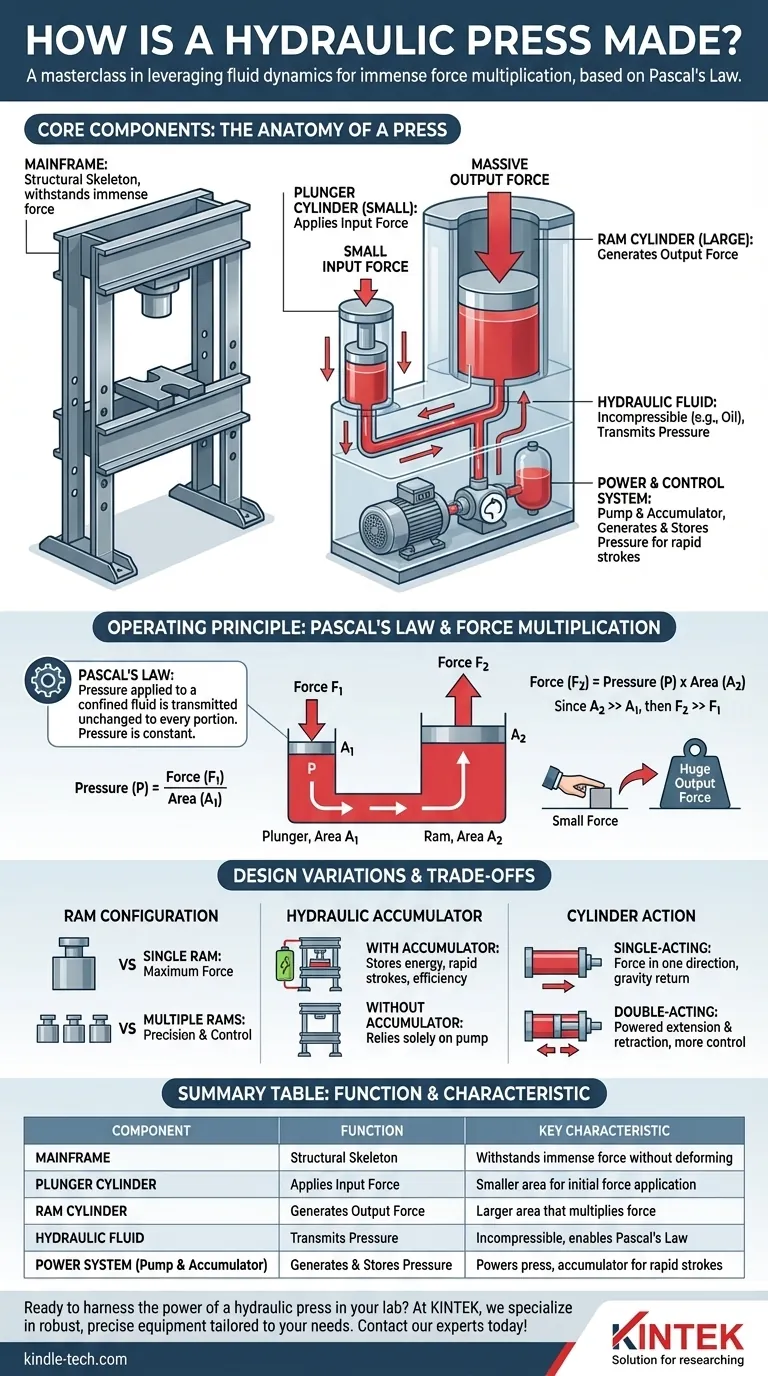

At its core, a hydraulic press is constructed from a few key components: a mainframe, two interconnected cylinders of different sizes (a small plunger and a large ram), and a power system that pumps hydraulic fluid between them. The entire assembly is designed not just to contain pressure, but to multiply force. This multiplication is achieved by leveraging a fundamental principle of fluid dynamics.

A hydraulic press is not built for strength alone; it is an engineered system designed to exploit Pascal's Law. The genius of its construction lies in using an incompressible fluid to convert a small input force on a small piston into a massive output force on a large piston.

The Core Components of a Hydraulic Press

A hydraulic press is an assembly of structural, hydraulic, and control elements. Each part has a distinct and critical function.

The Mainframe

The mainframe is the structural skeleton of the press. It must be incredibly robust to withstand the immense forces generated during operation without deforming.

The Hydraulic Cylinders (Plunger and Ram)

This two-cylinder system is the heart of the press.

The smaller cylinder, known as the plunger, is where the initial force is applied. The larger cylinder, called the ram, is what moves to perform the work, such as crushing or pressing an object. Both are connected by channels that allow fluid to pass between them.

The Hydraulic Fluid

An incompressible fluid, typically a specialized oil, fills the cylinders. Its primary job is to transmit pressure. Because it cannot be easily compressed, any pressure exerted on it in one part of the system is transferred equally throughout the entire system.

The Power and Control System

This system brings the press to life. It consists of a hydraulic pump that pressurizes the fluid and a hydraulic accumulator, which acts like a rechargeable battery for pressure. The accumulator stores high-pressure fluid, releasing it on demand for rapid, powerful thrusts.

The Operating Principle: Force Multiplication via Pascal's Law

Understanding how a press is "made" is inseparable from understanding the physics that make it work. The entire design is an application of Pascal's Law.

What is Pascal's Law?

This law states that pressure applied to a confined, incompressible fluid is transmitted unchanged to every portion of the fluid and the walls of the containing vessel. In simple terms: Pressure is constant everywhere within the system.

Applying Force to the Plunger

A relatively small mechanical force is applied to the plunger, pushing it down into the hydraulic fluid. This creates pressure within the fluid, which is calculated as Pressure = Force / Area.

Generating Immense Force at the Ram

Because the pressure is transmitted equally throughout the fluid, the same pressure is exerted on the much larger ram cylinder. However, because the ram has a much larger surface area, the resulting output force is magnified significantly.

The formula Force = Pressure x Area proves this. A small force on a small area creates a pressure that, when applied to a large area, results in a huge output force. This is the mechanical advantage of the hydraulic press.

Understanding the Trade-offs and Design Variations

Not all hydraulic presses are built the same way. The specific design is chosen based on the intended application and required performance.

Single vs. Multiple Rams

While a single large ram provides maximum force, many modern presses use a series of smaller rams. This configuration allows for much finer control over the distribution of force across the working surface.

The Role of the Hydraulic Accumulator

A press without an accumulator must rely solely on the pump for its power. Including an accumulator allows the system to store energy while idle and discharge it quickly for fast, powerful strokes, improving overall efficiency and cycle speed.

Single-Acting vs. Double-Acting Cylinders

A single-acting cylinder applies force in only one direction (usually extending). The return stroke is handled by gravity or springs. A double-acting cylinder uses hydraulic pressure to power both the extension and retraction strokes, offering more control and power.

Making the Right Choice for Your Goal

The construction of a hydraulic press is dictated by its intended purpose. Understanding the relationship between components and performance is key.

- If your primary focus is maximizing force: The ratio between the surface area of the ram and the plunger is the most critical design factor.

- If your primary focus is precision and control: A design featuring multiple smaller rams and a sophisticated hydraulic control system is superior to a single, massive ram.

- If your primary focus is speed and efficiency: A properly sized hydraulic pump paired with a hydraulic accumulator is essential to manage energy and enable rapid cycling.

Ultimately, the construction of a hydraulic press is a masterclass in leveraging physics to create a powerful tool from simple principles.

Summary Table:

| Component | Function | Key Characteristic |

|---|---|---|

| Mainframe | Structural Skeleton | Must withstand immense force without deforming |

| Plunger Cylinder | Applies Input Force | Smaller area where initial force is applied |

| Ram Cylinder | Generates Output Force | Larger area that multiplies force for work |

| Hydraulic Fluid | Transmits Pressure | Incompressible fluid (e.g., oil) that enables Pascal's Law |

| Power System (Pump & Accumulator) | Generates & Stores Pressure | Powers the press; accumulator enables rapid, powerful strokes |

Ready to harness the power of a hydraulic press in your lab?

At KINTEK, we specialize in providing robust and precise lab equipment, including hydraulic presses tailored to your specific research and production needs. Whether your goal is maximizing force, achieving precision, or improving efficiency, our expertise ensures you get the right solution.

Contact our experts today to discuss how a KINTEK hydraulic press can enhance your laboratory's capabilities and drive your projects forward.

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual Lab Heat Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

People Also Ask

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System