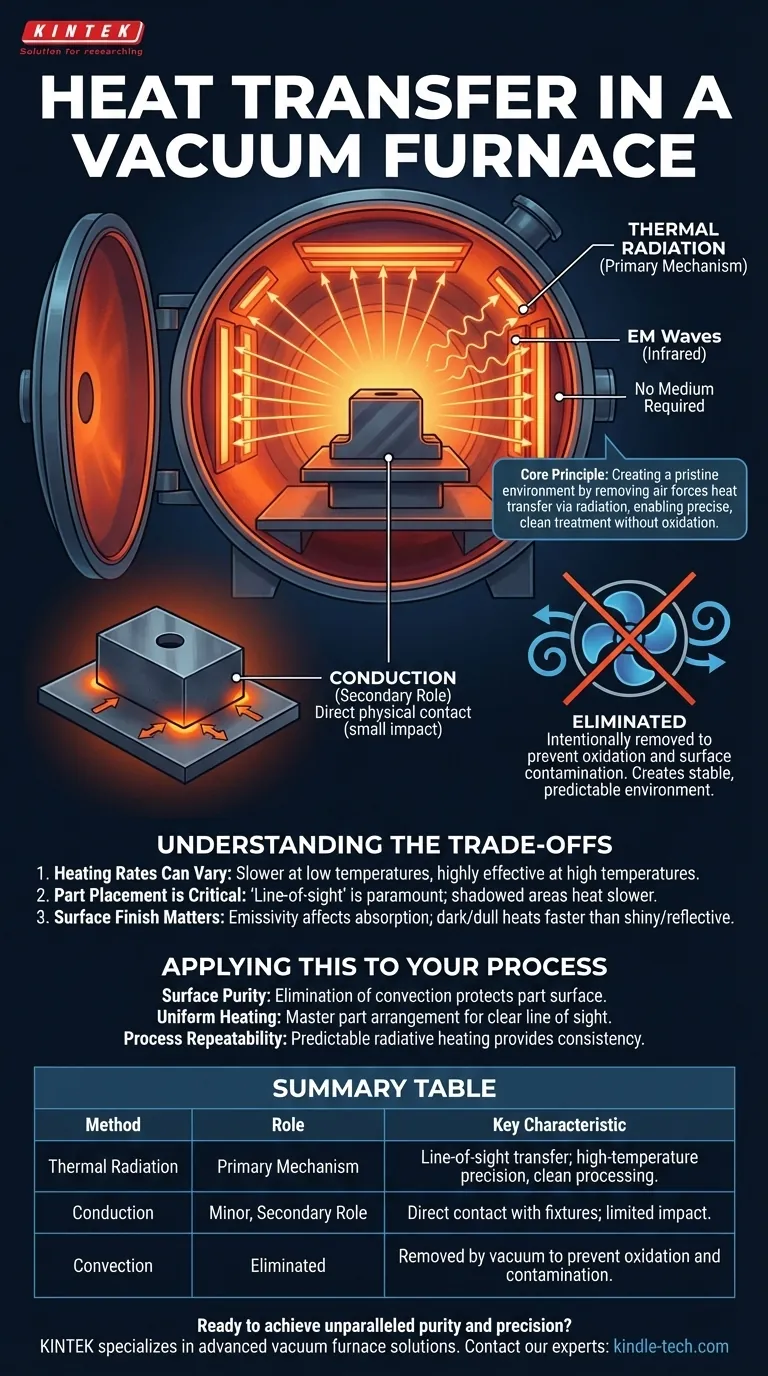

In a vacuum furnace, heat transfer is fundamentally different from a standard furnace. Because there is virtually no air to move heat around, the process relies almost exclusively on thermal radiation, with a secondary, minor role played by conduction through direct contact. Convection, the primary method in many conventional furnaces, is deliberately eliminated.

The core principle of a vacuum furnace is to create a pristine environment by removing air. This forces heat to transfer via radiation—electromagnetic waves traveling from the hot heating elements directly to the workpiece—enabling highly precise and clean heat treatment without the risk of oxidation.

The Dominant Role of Thermal Radiation

Unlike other forms of heat transfer, radiation does not require a medium. It's the same principle that allows the sun to heat the Earth through the vacuum of space.

How Radiation Works

All objects with a temperature above absolute zero emit thermal energy in the form of electromagnetic waves, primarily in the infrared spectrum. Hotter objects radiate significantly more energy than cooler ones.

In a vacuum furnace, powerful heating elements (often made of graphite or refractory metals like molybdenum) are heated electrically to very high temperatures. These elements then radiate thermal energy in all directions.

A Line-of-Sight Process

This radiated energy travels in straight lines until it strikes the workpiece, where it is absorbed and converted back into heat. This "line-of-sight" nature is a critical factor in how vacuum furnaces operate and how parts must be arranged inside them.

The Supporting Role of Conduction

Conduction is heat transfer through direct physical contact. While it is not the primary mechanism, it still plays a part.

Points of Direct Contact

The workpiece rests on a hearth or fixture inside the furnace. Heat will conduct from the hot fixture directly into the part at these points of contact.

However, because the contact area is typically very small compared to the total surface area of the part, the amount of heat transferred via conduction is usually minor compared to the energy absorbed through radiation.

Why Convection is Deliberately Eliminated

In a conventional furnace, fans circulate hot air, transferring heat through convection. This process is intentionally removed in a vacuum furnace.

The Purpose of the Vacuum

The main reason for using a vacuum is to remove oxygen and other atmospheric gases. These gases cause oxidation, discoloration, and surface contamination at high temperatures, which can ruin sensitive metal parts.

By removing the air, you remove the medium for convection. This not only prevents contamination but also creates a highly stable and predictable heating environment, free from the chaotic swirls and currents of moving air.

Understanding the Trade-offs

This reliance on radiation creates a unique set of operating considerations that differ from conventional heat treatment.

Heating Rates Can Vary

At lower temperatures, heat transfer by radiation is less efficient than forced convection. This can sometimes lead to longer initial heating times in a vacuum furnace. However, at very high temperatures, radiation becomes an extremely effective and rapid mode of heat transfer.

Part Placement is Critical

Because radiation requires a direct line of sight, part geometry and placement are paramount. Any surface "shadowed" by another part or a feature on the part itself will not heat at the same rate. This requires careful planning to ensure uniform temperature.

Surface Finish Matters

The ability of a material to absorb radiated energy is known as its emissivity. A dull, dark surface absorbs heat much more effectively than a shiny, reflective one. This means two parts made of the same alloy but with different surface finishes may heat at different rates.

Applying This to Your Process

Understanding these heat transfer principles allows for better control over the final product.

- If your primary focus is surface purity and preventing oxidation: The elimination of convection is the key benefit, as the vacuum environment is what protects the part's surface.

- If your primary focus is uniform heating: You must master part arrangement to ensure all critical surfaces have a clear line of sight to the heating elements.

- If your primary focus is process repeatability: The predictable, stable nature of radiative heating, free from turbulent convection currents, provides unparalleled consistency from one cycle to the next.

Mastering the physics of heat transfer in a vacuum is the first step to leveraging the full power and precision of this technology.

Summary Table:

| Heat Transfer Method | Role in Vacuum Furnace | Key Characteristic |

|---|---|---|

| Thermal Radiation | Primary Mechanism | Line-of-sight transfer via electromagnetic waves; enables high-temperature precision and clean processing. |

| Conduction | Minor, Secondary Role | Heat transfer through direct contact with fixtures; limited impact compared to radiation. |

| Convection | Eliminated | Intentionally removed by vacuum to prevent oxidation and surface contamination. |

Ready to achieve unparalleled purity and precision in your heat-treating processes?

KINTEK specializes in advanced vacuum furnace solutions for laboratories and industrial facilities. Our equipment leverages precise radiative heat transfer to deliver contamination-free results, perfect for sensitive materials and critical applications.

Contact our experts today to discuss how a KINTEK vacuum furnace can optimize your lab's efficiency and product quality.

Visual Guide

Related Products

- Molybdenum Vacuum Heat Treat Furnace

- Vacuum Heat Treat Furnace with Ceramic Fiber Liner

- Vacuum Heat Treat Sintering Brazing Furnace

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

People Also Ask

- What is classification of heating furnace? A Guide to Selecting the Right Industrial Furnace

- Why is a vacuum oven necessary for pre-treating PBS and BP? Ensure Composite Integrity via Advanced Dehydration

- How is radiation responsible for heat transfer through vacuum? Unlocking the Science of Thermal Radiation

- What is the function of the EAF? Powering a Sustainable, Agile Future for Steel Production

- What is the relationship between temperature and pressure in a vacuum? Mastering Thermal Control for Optimal Vacuum Performance

- How does vacuum hardening work? Achieve Superior Precision and Surface Quality for Your Metal Parts

- What are industrial vacuum systems? A Guide to Boosting Efficiency in Material Handling & Processing

- Why is a high-temperature furnace required for ISR in 5Cr-0.5Mo steel? Prevent Hydrogen Cracking & Residual Stress