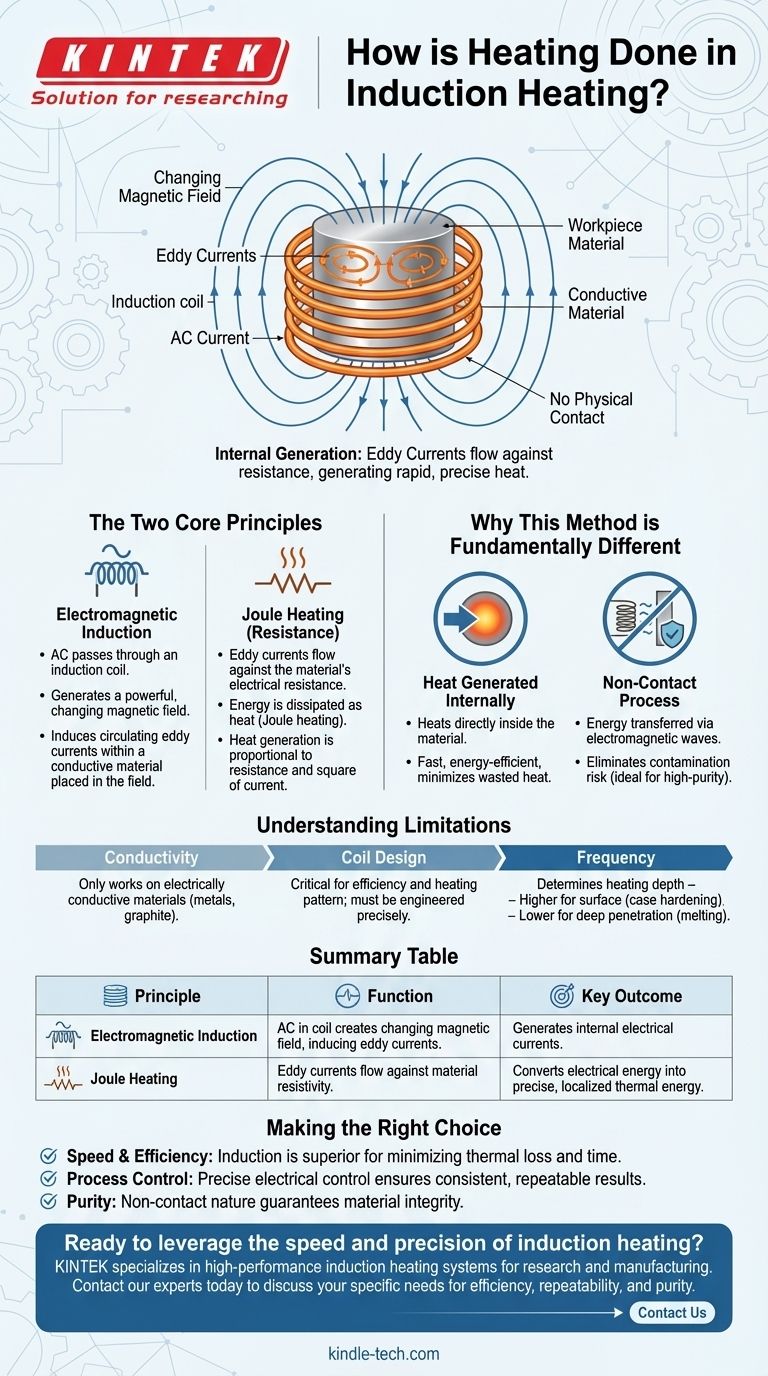

In essence, induction heating works by using a changing magnetic field to generate electrical currents directly inside a conductive object. These internal currents, known as eddy currents, flow against the material's natural electrical resistance, which in turn generates precise and rapid heat. It effectively turns the object into its own heating element without any physical contact.

The process relies on two fundamental physics principles working in tandem: electromagnetic induction creates the current, and Joule heating converts that current into thermal energy. This non-contact method is why induction heating is exceptionally fast, clean, and controllable.

The Two Core Principles of Induction Heating

To truly understand how induction works, we must look at the two distinct physical phenomena that make it possible. It's a two-step process that happens almost instantaneously.

Principle 1: Electromagnetic Induction

An alternating electrical current (AC) is passed through an induction coil, typically made of copper.

According to Faraday's Law of Induction, this alternating current in the coil generates a powerful and rapidly changing magnetic field around it.

When a conductive material, such as a piece of metal, is placed within this magnetic field, the field induces circulating electrical currents inside the metal. These are called eddy currents.

Principle 2: Joule Heating (Resistance)

These induced eddy currents are not flowing through a perfect conductor. The metal itself has a specific electrical resistivity.

As the eddy currents flow against this resistance, energy is dissipated in the form of heat. This phenomenon is known as Joule heating.

The amount of heat generated is directly proportional to the material's resistance and the square of the current, allowing for intense and localized heating.

Why This Method is Fundamentally Different

The internal nature of induction heating gives it significant advantages over traditional methods like flame or resistance furnaces, which apply heat externally.

Heat is Generated Internally

Unlike an oven that heats the surface of an object and relies on slow thermal conduction to heat the core, induction generates heat directly inside the material.

This internal generation is the primary reason induction heating is so incredibly fast and energy-efficient, as less heat is wasted warming the surrounding air.

A Completely Non-Contact Process

The energy is transferred via electromagnetic waves, meaning the induction coil never touches the workpiece.

This is a critical advantage in high-purity applications, such as in the medical or semiconductor industries, as it completely eliminates the risk of contamination that can occur with direct flame or contact heating.

Understanding the Trade-offs and Limitations

While powerful, induction heating is not a universal solution. Its effectiveness is governed by specific physical constraints that are critical to understand.

Material Conductivity is Non-Negotiable

The entire process hinges on electromagnetic induction. Therefore, it only works on materials that are electrically conductive, such as metals, graphite, or certain semiconductors.

It cannot directly heat electrical insulators like most ceramics, glass, or plastics.

Coil Design Governs the Outcome

The efficiency and pattern of the heating are heavily dependent on the design of the induction coil.

The shape of the coil and its proximity to the workpiece must be carefully engineered to concentrate the magnetic field precisely where heat is needed, ensuring consistent and controlled results.

Frequency Determines Heating Depth

The frequency of the alternating current is a key control parameter. Higher frequencies tend to generate heat only on the surface of the material, which is ideal for case hardening.

Lower frequencies penetrate deeper into the material, making them suitable for processes like melting or through-heating large billets.

Making the Right Choice for Your Goal

Selecting a heating method depends entirely on the requirements of your application. Induction offers distinct benefits for specific outcomes.

- If your primary focus is speed and energy efficiency: Induction heating is superior because it generates heat directly inside the workpiece, minimizing thermal loss and process time.

- If your primary focus is process control and repeatability: The precise electrical control over the magnetic field allows for highly consistent and repeatable thermal cycles, essential for modern manufacturing.

- If your primary focus is purity and avoiding contamination: The non-contact nature of induction heating makes it the ideal choice, guaranteeing the material is never compromised by external elements.

By leveraging these principles, you can apply induction heating as a precise, fast, and exceptionally clean tool for the most demanding thermal applications.

Summary Table:

| Principle | Function | Key Outcome |

|---|---|---|

| Electromagnetic Induction | AC current in a coil creates a changing magnetic field, inducing eddy currents in a conductive workpiece. | Generates electrical currents internally within the material. |

| Joule Heating (Resistance) | Eddy currents flow against the material's electrical resistivity, dissipating energy as heat. | Converts electrical energy into precise, localized thermal energy. |

Ready to leverage the speed and precision of induction heating in your lab?

KINTEK specializes in high-performance lab equipment, including induction heating systems, designed to meet the rigorous demands of modern research and manufacturing. Our solutions deliver the fast, clean, and controllable heat you need for processes like melting, brazing, and heat treatment.

Contact our experts today to discuss how we can provide the right induction heating equipment to enhance your lab's efficiency, repeatability, and purity.

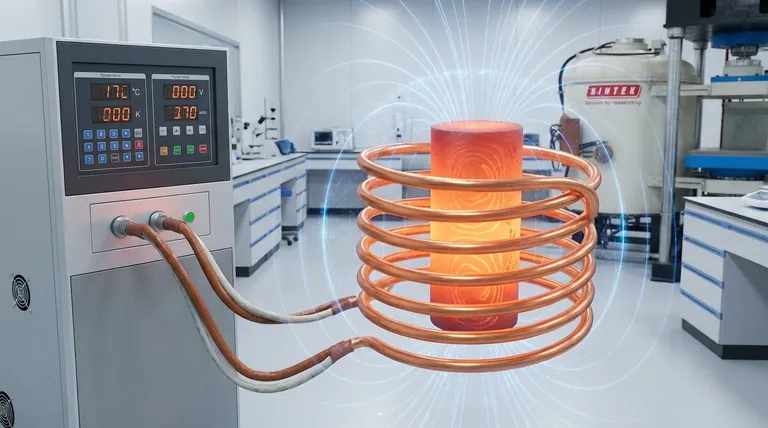

Visual Guide

Related Products

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- Silicon Carbide SiC Thermal Heating Elements for Electric Furnace

- Lab-Scale Vacuum Induction Melting Furnace

- Platinum Sheet Electrode for Laboratory and Industrial Applications

- Double Plate Heating Press Mold for Lab

People Also Ask

- How does the vacuum hot pressing process affect the properties of finished materials? Maximize Density and Performance

- What are the advantages of a vacuum hot-press furnace? Superior Bonding for Diamond/Aluminum Composites

- How does the mechanical pressure from a vacuum hot-pressing furnace facilitate the densification of B4C/Al composites?

- How does the vacuum environment in a vacuum hot press furnace protect CoCrCuFeNi? Prevent oxidation for high-purity HEAs.

- What are the benefits of using a vacuum hot pressing furnace to synthesize high-density Mo2Ga2C? Achieve 98.8% Density.