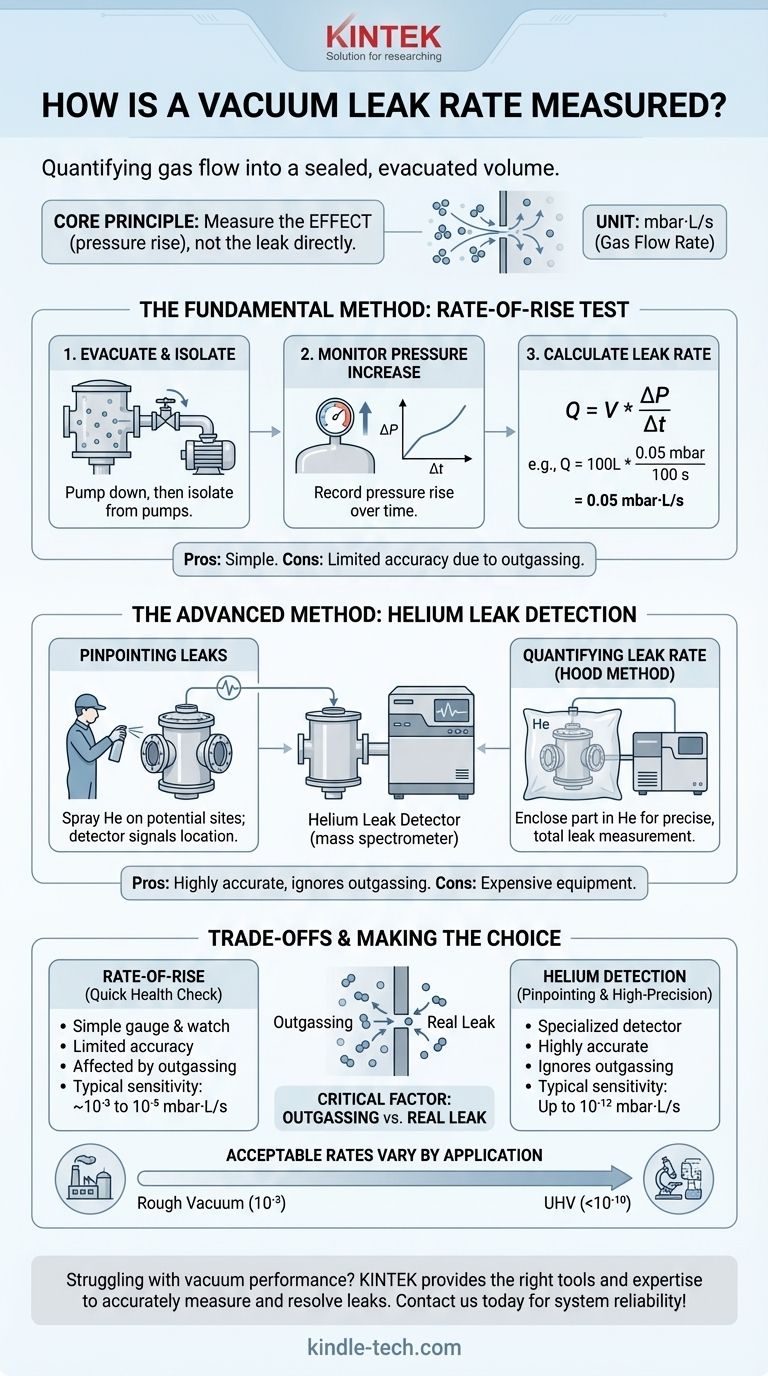

In short, a vacuum leak rate is measured by quantifying the amount of gas entering a sealed, evacuated volume over a specific period. This is typically expressed in units of pressure-volume per time, such as millibar-liters per second (mbar·L/s), which represents a specific quantity of gas molecules flowing into the system.

The core principle is not to measure the leak directly, but to measure its effect. By isolating a vacuum chamber from its pumps and monitoring how quickly the pressure rises, you can calculate the rate at which gas is entering the system.

The Fundamental Method: The Rate-of-Rise Test

The most common and direct way to measure a system's total leak rate is the rate-of-rise (or pressure rise) test. It relies on a simple and powerful principle.

Step 1: Evacuate and Isolate

First, the vacuum chamber is pumped down to a pressure significantly lower than its target operating pressure. Once this base pressure is reached, the chamber is completely isolated from the vacuum pumps by closing a main valve.

Step 2: Monitor the Pressure Increase

With the pumps isolated, any gas entering the chamber through leaks will cause the internal pressure to rise. A pressure gauge is used to record this pressure increase over a measured amount of time.

Step 3: Calculate the Leak Rate

The leak rate (Q) is then calculated using the chamber's known internal volume (V) and the measured rate of pressure change (ΔP/Δt).

The formula is: Q = V * (ΔP / Δt)

For example, if a 100-liter chamber's pressure rises by 0.05 mbar over 100 seconds, the leak rate is calculated as: Q = 100 L * (0.05 mbar / 100 s) = 0.05 mbar·L/s

The Unit Explained: mbar·L/s

This unit can feel abstract, but it represents a physical quantity of gas. Based on the ideal gas law (PV=nRT), the term "pressure × volume" (mbar·L) is proportional to the number of gas molecules. Therefore, mbar·L/s quantifies the flow rate of gas molecules into the system.

Advanced Method: Helium Leak Detection

While the rate-of-rise test measures the total leak rate, it doesn't help you find the leak's location. For this, and for measuring extremely small leaks, a helium leak detector is the industry standard.

How It Works

A helium leak detector is a specialized mass spectrometer tuned to be exceptionally sensitive to helium atoms. The detector is attached to the vacuum system, which is kept under vacuum.

Finding the Leak's Location

An operator then sprays a small amount of helium gas on the exterior of the vacuum chamber, targeting potential leak sites like welds, flanges, and seals. If helium enters the system through a leak, it travels to the detector, which registers a signal, pinpointing the leak's location.

Quantifying the Leak Rate

To get a precise leak rate measurement, the part being tested can be placed inside a bag or enclosure filled with a known concentration of helium (the "hood" method). The amount of helium detected inside the vacuum system over time gives a highly accurate and quantifiable leak rate.

Understanding the Trade-offs and Pitfalls

Measuring leak rates is not without its challenges. The method you choose depends on the accuracy you need and the type of system you are evaluating.

The Problem of Outgassing

A major issue with the rate-of-rise test is outgassing. This is the process where molecules trapped on the internal surfaces of the chamber are released into the vacuum, also causing the pressure to rise. This effect can easily be mistaken for a real atmospheric leak, leading to an overestimation of the leak rate.

Accuracy vs. Simplicity

The rate-of-rise test is simple and requires only a pressure gauge and a watch, but its accuracy is limited, especially in very clean, high-vacuum systems where outgassing can be the dominant factor.

The Precision of Helium

A helium leak detector is far more accurate because it ignores outgassing (which is mostly water vapor, nitrogen, etc.) and only measures the tracer gas. However, this requires expensive, specialized equipment.

What is an "Acceptable" Leak Rate?

An acceptable leak rate is entirely dependent on the application. A system for handling rough vacuum might tolerate a leak of 10⁻³ mbar·L/s, while a high-end research system operating at ultra-high vacuum (UHV) may require a total leak rate below 10⁻¹⁰ mbar·L/s.

Making the Right Choice for Your Goal

Your measurement strategy should align with your system's requirements.

- If your primary focus is a quick health check of a rough or medium vacuum system: The rate-of-rise test is sufficient to determine if a significant leak is compromising performance.

- If your primary focus is pinpointing a leak's location for repair: A helium leak detector used in "sniffer" mode is the most effective and essential tool.

- If your primary focus is qualifying a component for high or ultra-high vacuum: A quantitative helium leak test (like the hood method) is necessary to certify that the part meets stringent performance standards.

Understanding how to properly measure a vacuum leak is the first step toward diagnosing problems and achieving a stable, high-performing vacuum system.

Summary Table:

| Method | Primary Use | Key Advantage | Typical Sensitivity (mbar·L/s) |

|---|---|---|---|

| Rate-of-Rise Test | Quick system health check | Simple, requires only a pressure gauge | ~10⁻³ to 10⁻⁵ |

| Helium Leak Detection | Pinpointing leaks & high-precision measurement | Highly accurate, ignores outgassing | Up to 10⁻¹² |

Struggling with vacuum system performance? Unstable pressure or contamination can ruin experiments and processes. KINTEK specializes in lab equipment and consumables, providing the right tools and expertise to accurately measure and resolve vacuum leaks. Our solutions help you achieve and maintain the precise vacuum integrity your laboratory demands. Contact us today (#ContactForm) to discuss your specific application and ensure your system's reliability!

Visual Guide

Related Products

- Laboratory Vertical Water Circulating Vacuum Pump for Lab Use

- Circulating Water Vacuum Pump for Laboratory and Industrial Use

- KF ISO Stainless Steel Vacuum Flange Blind Plate for High Vacuum Systems

- Laboratory Benchtop Water Circulating Vacuum Pump for Lab Use

- Molybdenum Tungsten Tantalum Special Shape Evaporation Boat

People Also Ask

- What are the units for vacuum pressure? Torr, mbar, and Pascal Explained

- What are the 5 factors that affect the rate of evaporation? Master the Process for Your Lab

- What are the preventive maintenance of hydraulic systems? Extend Equipment Life and Maximize Uptime

- What are the overall advantages of using vacuum pumps? Achieve Unmatched Process Control & Efficiency

- What happens if a hydraulic system leaks? Prevent Costly Damage and Safety Hazards