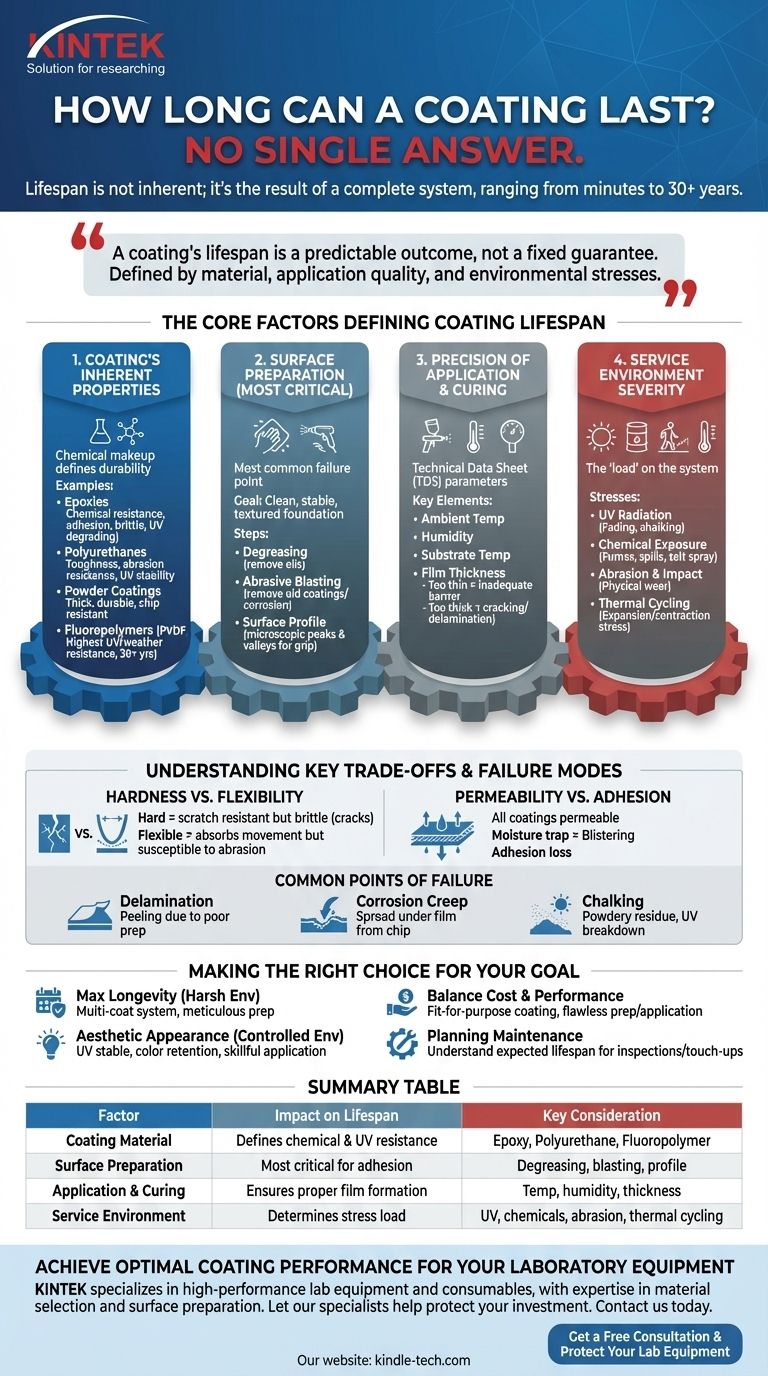

There is no single answer to how long a coating can last, as its lifespan is not an inherent property but the result of a complete system. The functional life can range from mere minutes for a temporary lubricant to over 30 years for a high-performance architectural coating. A coating’s durability is determined by its chemical composition, the quality of surface preparation, the precision of its application, and the severity of its operating environment.

A coating's lifespan is a predictable outcome, not a fixed guarantee. It is fundamentally defined by the interaction between the coating material, its application quality, and the environmental stresses it must endure.

The Core Factors Defining Coating Lifespan

A coating system is only as strong as its weakest link. To accurately predict or extend a coating's service life, you must consider four critical components.

1. The Coating's Inherent Properties

The chemical makeup of the coating itself establishes its potential for durability. Different formulations are engineered for different threats.

- Epoxies are known for excellent chemical resistance and adhesion but can be brittle and degrade under UV exposure (chalking).

- Polyurethanes offer superior toughness, abrasion resistance, and UV stability, often used as a topcoat over an epoxy primer.

- Powder Coatings provide a thick, durable, and uniform finish that is highly resistant to chipping and scratches.

- Fluoropolymers (e.g., PVDF) offer the highest level of UV and weather resistance, often specified for monumental architecture where lifespans of 30+ years are required.

2. The Critical Role of Surface Preparation

This is the most common point of failure for any coating system. An improperly prepared surface guarantees premature failure, regardless of the coating's quality.

The primary goal of surface preparation is to create a clean, stable, and properly textured foundation for the coating to bond to.

Key steps include degreasing to remove oils, abrasive blasting (or sanding/grinding) to remove old coatings and corrosion, and achieving a specific surface profile—microscopic peaks and valleys that the coating can mechanically grip.

3. The Precision of Application and Curing

A perfect coating material and a perfectly prepared surface can still fail if the application is flawed.

Every coating has a technical data sheet (TDS) specifying its ideal application parameters. This includes ambient temperature, humidity, and the substrate temperature. Applying outside these windows can compromise adhesion and curing.

Film thickness is also critical. Too thin, and the coating won't provide an adequate barrier. Too thick, and it can crack, fail to cure properly, or delaminate under stress.

4. The Severity of the Service Environment

The environment is the "load" placed on the coating system. Understanding the specific stresses is essential for selecting the right material.

- UV Radiation: Sunlight breaks down the polymer chains in many coatings, causing them to lose color (fade) and integrity (chalk).

- Chemical Exposure: Industrial fumes, spills, or even salt spray in coastal areas can aggressively attack the coating.

- Abrasion and Impact: Physical wear and tear from foot traffic, moving equipment, or impacts can mechanically destroy the coating.

- Thermal Cycling: Constant expansion and contraction of the underlying substrate due to temperature changes puts immense stress on the coating's bond.

Understanding Key Trade-offs and Failure Modes

No coating is perfect for every situation. Choosing the right one involves balancing competing properties and understanding how they can fail.

Hardness vs. Flexibility

A very hard coating may offer excellent scratch resistance but can be too brittle to handle the expansion and contraction of a metal substrate, leading to stress cracks. A more flexible coating can absorb this movement but may be more susceptible to abrasion.

Permeability vs. Adhesion

All coatings have some degree of permeability, meaning moisture can slowly pass through them. A problem arises when moisture gets trapped between the coating and the substrate, which can lead to blistering (osmotic blistering) or loss of adhesion.

Common Points of Failure

- Delamination: The most common failure, where the coating peels away from the substrate or from a layer below it. This is almost always due to poor surface preparation or intercoat contamination.

- Corrosion Creep: When a small chip or scratch allows corrosion to begin, and it then spreads underneath the coating film from that initial breach.

- Chalking: A powdery residue that forms on the surface as the coating's polymer binder is broken down by UV radiation. This is an early sign of coating degradation.

Making the Right Choice for Your Goal

By analyzing the coating as a system, you can shift from asking "how long will it last?" to "how do I ensure it lasts for its intended service life?"

- If your primary focus is maximum longevity in a harsh environment: Prioritize a multi-coat system (e.g., zinc-rich primer, epoxy mid-coat, polyurethane topcoat) and view meticulous surface preparation as non-negotiable.

- If your primary focus is aesthetic appearance in a controlled environment: Focus on a coating with excellent UV stability and color retention, ensuring the application is done skillfully to achieve a uniform finish.

- If your primary focus is balancing cost and performance: Select a proven, fit-for-purpose industrial coating and invest the majority of your budget and effort into flawless surface preparation and application.

- If your primary focus is planning for maintenance: Understand the expected lifespan of your chosen system to schedule regular inspections, allowing you to perform touch-ups before a small failure becomes a catastrophic one.

Ultimately, you have significant control over a coating's lifespan by investing in the right material, surface preparation, and application quality for the environment it will face.

Summary Table:

| Factor | Impact on Lifespan | Key Consideration |

|---|---|---|

| Coating Material | Defines chemical & UV resistance | Epoxy, Polyurethane, Powder, Fluoropolymer |

| Surface Preparation | Most critical for adhesion | Degreasing, abrasive blasting, surface profile |

| Application & Curing | Ensures proper film formation | Temperature, humidity, film thickness |

| Service Environment | Determines the stress load | UV exposure, chemicals, abrasion, thermal cycling |

Achieve optimal coating performance and longevity for your laboratory equipment. The lifespan of your protective coatings is critical to maintaining the integrity and accuracy of your lab work. At KINTEK, we specialize in providing high-performance lab equipment and consumables, backed by expertise in material selection and surface preparation. Let our specialists help you select and apply the right coating system to protect your investment against harsh chemical and physical environments. Contact us today to discuss your specific needs and ensure your lab surfaces are protected for the long term.

Get a Free Consultation & Protect Your Lab Equipment

Visual Guide

Related Products

- Custom CVD Diamond Coating for Lab Applications

- Custom Machined and Molded PTFE Teflon Parts Manufacturer with PTFE Crucible and Lid

- Custom PTFE Teflon Parts Manufacturer for PTFE Measuring Cylinder 10/50/100ml

- Optical Ultra-Clear Glass Sheet for Laboratory K9 B270 BK7

- High-Purity Titanium Foil and Sheet for Industrial Applications

People Also Ask

- Why KBr is used to prepare samples for FTIR analysis? Unlock Clear, High-Quality Spectra

- What does a hot air oven do in a laboratory? Essential Sterilization & Drying for Your Lab

- How is a sample analysis done in FTIR? A Step-by-Step Guide to Reliable Results

- What is the physics of sputtering? A Guide to Thin Film Deposition by Momentum Transfer

- What are the advantages of RF sputtering? Unlock Versatile Thin Film Deposition for Insulators

- What is the principle of rota evaporation? A Guide to Gentle, Efficient Solvent Separation

- Why is a vacuum distillation system necessary during the synthesis of rosin allyl esters? Protect Product Integrity

- What is the future potential for biomass? Unlocking a Sustainable Bioeconomy