The time required to anneal metal is not a single number but a variable that can range from a few minutes for thin pieces of non-ferrous metal to over 24 hours for large, complex steel components. The total duration depends entirely on the metal's type, its mass and thickness, and the specific properties you aim to achieve. The process is governed by the time it takes to heat the material uniformly, hold it at the correct temperature to restructure its atoms, and then cool it at the appropriate rate.

The core principle of annealing is not about hitting a time on a stopwatch, but about achieving a specific metallurgical transformation. The "correct" amount of time is simply the time required for the material's entire mass to reach its recrystallization temperature and then cool slowly enough to ensure maximum softness and ductility.

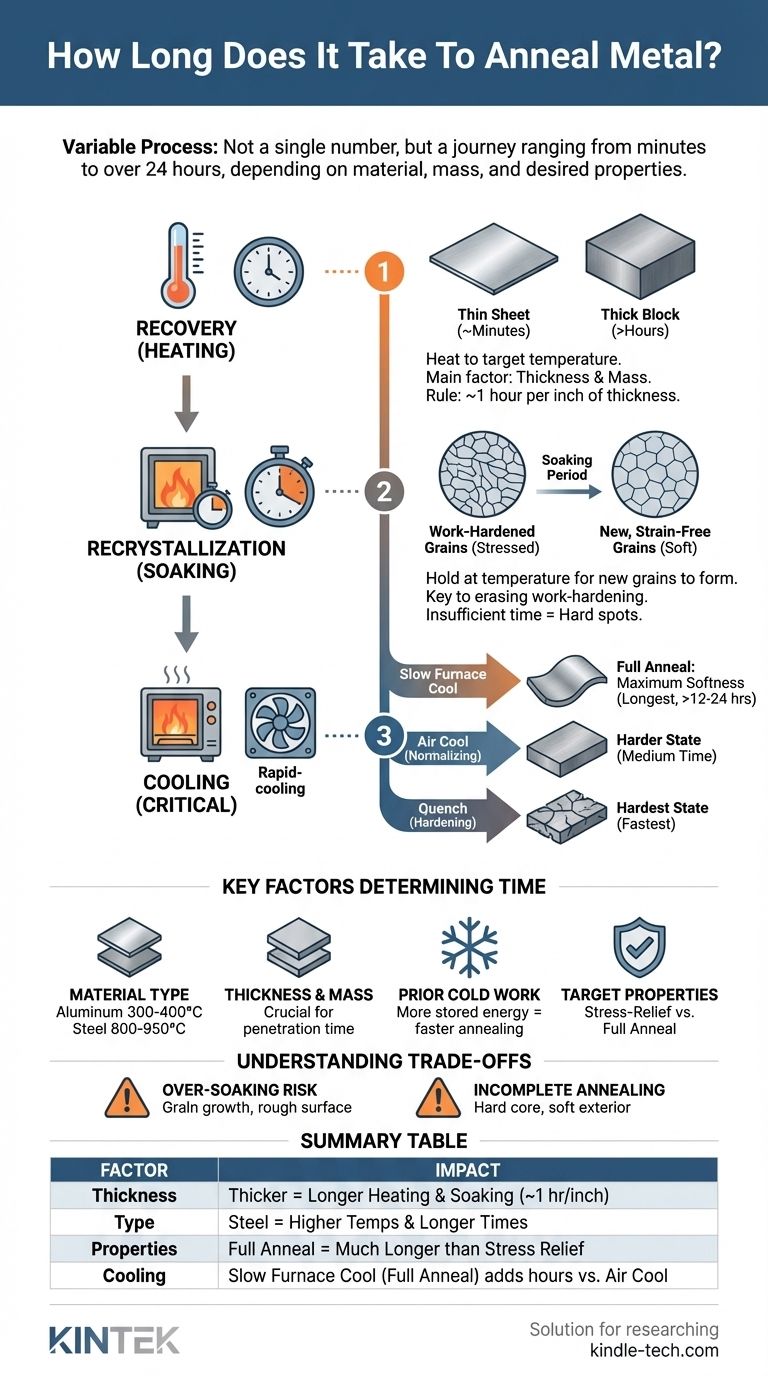

The Three Stages of Annealing Time

Annealing isn't a single event but a three-part process. The total time is the sum of these three distinct stages, each serving a critical function.

1. The Recovery Stage (Heating)

This is the time it takes to heat the material to its target annealing temperature. The primary factor influencing this stage is the material's thickness and overall mass.

A thin sheet of aluminum may heat up in minutes, while a four-inch thick block of tool steel can take several hours for the heat to "soak" through from the surface to the core. A common rule of thumb is to budget one hour of heating time for every inch of thickness.

2. The Recrystallization Stage (Soaking)

Once the material reaches its target temperature, it is "soaked" or held at that temperature for a set period. This is where the actual annealing happens.

During soaking, new, strain-free grains form and grow within the metal, erasing the effects of work-hardening and relieving internal stresses. Insufficient soaking results in an incomplete anneal, leaving hard spots.

3. The Cooling Stage

This is often the longest part of the process and is absolutely critical to the outcome. For a full anneal, the goal is maximum softness, which requires a very slow cooling rate.

This is typically achieved by leaving the part inside the furnace and shutting the power off, allowing it to cool with the furnace's insulation over many hours, sometimes 12 to 24 or more. A faster cool, such as removing the part into still air, results in a different, harder microstructure and is technically a process called normalizing, not annealing.

Key Factors That Determine Annealing Time

Several variables dictate the time required for a successful anneal. Understanding them allows you to move from guessing to making an educated process decision.

Material Type

Different metals and alloys have vastly different annealing temperatures and thermal conductivity. Aluminum anneals at a much lower temperature (e.g., 300-400°C / 570-750°F) than steel (e.g., 800-950°C / 1475-1750°F). These temperatures directly impact the heating and soaking time required.

Material Thickness and Mass

This is the most significant factor. Heat must penetrate the entire cross-section of the part. The "one hour per inch of thickness" guideline is a safe starting point for the soaking stage, but the initial heating to get the core to temperature must also be accounted for.

Degree of Prior Cold Work

A heavily work-hardened material (one that has been bent, hammered, or drawn extensively) has more stored internal energy. This energy acts as a driving force for recrystallization, meaning it will anneal faster at a given temperature than a material that has only been lightly worked.

Target Properties

The specific goal dictates the process. A stress-relief anneal, intended only to remove internal stresses from welding or machining, requires a lower temperature and shorter soak time than a full anneal, which is designed to achieve the softest possible state for the metal.

Understanding the Trade-offs: Time vs. Properties

More time is not always better. The duration of each stage involves critical trade-offs that affect the final quality of the component.

The Risk of Over-Soaking

Holding a metal at its annealing temperature for too long can cause excessive grain growth. While the material will be very soft, large grains can lead to a rough surface finish (known as "orange peel") after forming and, in some cases, reduced toughness.

The Problem of Incomplete Annealing

Rushing the process is a common failure. If the soaking time is too short or the heating is too fast, the core of the material may never reach the full annealing temperature. This leaves the part with a soft exterior but a hard, brittle interior, defeating the purpose of the process.

The Critical Role of Cooling Rate

The cooling rate has the most dramatic effect on the final properties and the total process time.

- Slow Furnace Cool: Produces the softest, most ductile state. (Longest time)

- Air Cool (Normalizing): Produces a harder, stronger state than annealed. (Medium time)

- Quench (Hardening): Produces the hardest, most brittle state. (Fastest time)

Choosing to anneal means committing to the slow, controlled cooling phase.

Making the Right Choice for Your Goal

Instead of seeking a single number, determine the correct process by defining your objective.

- If your primary focus is maximum softness for extreme forming or machining: You need a true "full anneal." Plan for a long cycle that includes heating for at least one hour per inch of thickness, soaking for at least one hour per inch, and a very slow furnace cool that could take over 12 hours.

- If your primary focus is simply relieving stress from welding or fabrication: A sub-critical anneal is sufficient. This involves a shorter time at a lower temperature, followed by a slow cool, which can often be completed in a few hours.

- If you are a hobbyist or blacksmith working with unknown steel: Heat the metal to its non-magnetic temperature (a dull red to cherry red, depending on ambient light), ensure it is evenly heated, and then bury it in an insulating material like vermiculite or dry wood ash to cool as slowly as possible overnight.

Ultimately, understanding the principles of heating, soaking, and cooling is far more valuable than memorizing a specific time.

Summary Table:

| Factor | Impact on Annealing Time |

|---|---|

| Material Thickness | Thicker parts require longer heating and soaking (approx. 1 hour per inch). |

| Metal Type | Steel requires higher temperatures and longer times than aluminum. |

| Target Properties | A full anneal for maximum softness takes much longer than a stress relief. |

| Cooling Method | Slow furnace cooling (full anneal) adds hours vs. air cooling (normalizing). |

Achieve Precise Metallurgical Results with KINTEK

Mastering the delicate balance of time and temperature is key to successful annealing. Whether your goal is maximum softness for forming or simple stress relief after fabrication, the right equipment ensures consistent, high-quality results.

KINTEK specializes in the lab equipment and consumables that laboratories rely on for precise thermal processing. Our furnaces are engineered for uniform heating and controlled cooling cycles, giving you the repeatability needed for critical applications.

Let our experts help you optimize your annealing process. Contact us today to discuss your specific metal types and project requirements. We'll help you select the right equipment to achieve your desired material properties efficiently and reliably.

Visual Guide

Related Products

- 1800℃ Muffle Oven Furnace for Laboratory

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1700℃ Muffle Oven Furnace for Laboratory

- High Temperature Muffle Oven Furnace for Laboratory Debinding and Pre Sintering

- 1400℃ Muffle Oven Furnace for Laboratory

People Also Ask

- How does a high-temperature furnace with oxygen flow control ensure the quality of SiO2 layers? Achieve Precision Growth

- What is the difference between a vacuum furnace and an inert gas furnace? Choose the Right Heat Treatment Process

- Why is vacuum drying equipment required for carbide production? Preserve Powder Purity & Prevent Cobalt Oxidation

- What is the advantages of vacuum hardening? Achieve Pristine Surfaces and Unmatched Precision

- What are the safety precautions for heat treatment furnace? Protect Your Lab from Extreme Heat and High Voltage

- What is microwave sintering furnace? Unlock Faster, More Uniform Thermal Processing

- Why is an industrial vacuum oven required for the purification of fluorosilicone rubber? Ensure Purity and Performance

- What is the temperature used in hardening? Master the Key to Steel Hardening Success