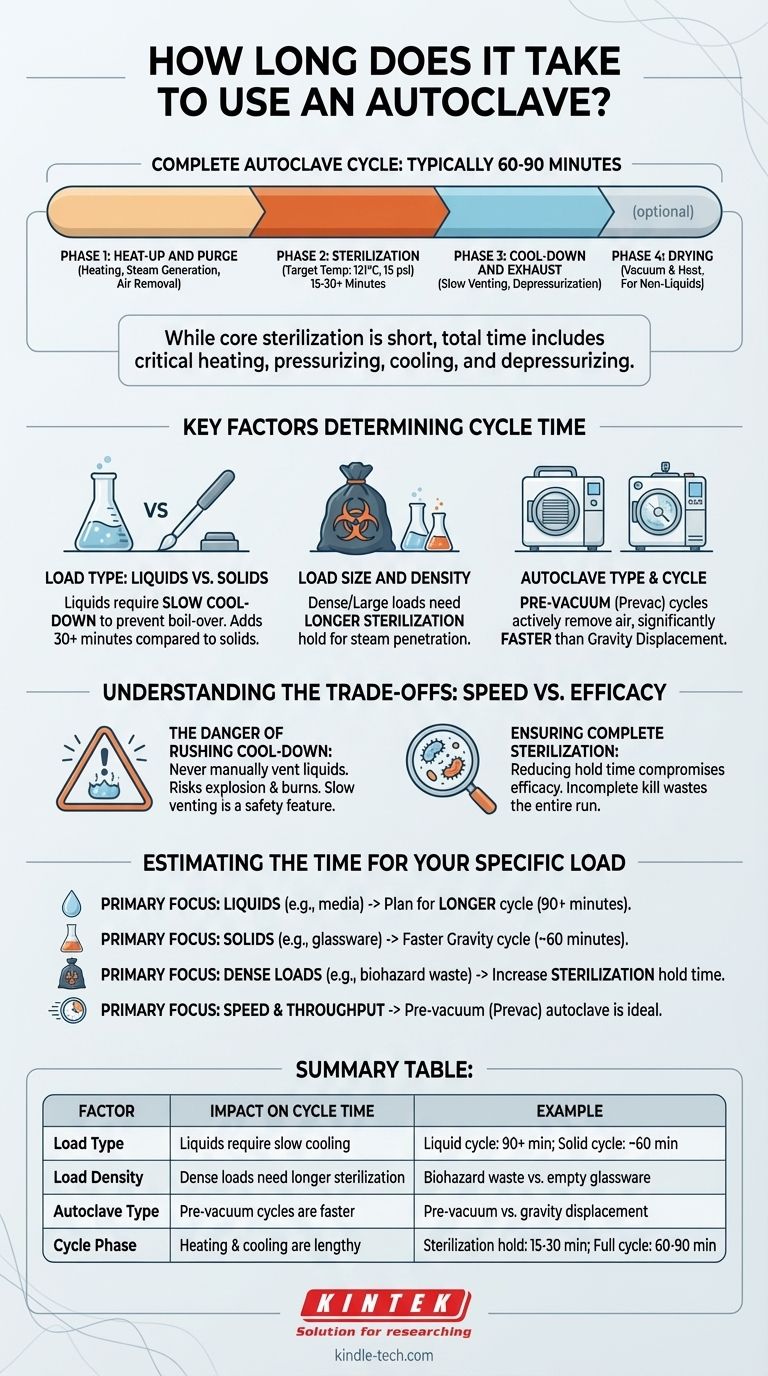

A complete autoclave cycle typically takes between 60 to 90 minutes from start to finish. While the core sterilization phase at the target temperature might only last 15 to 30 minutes, the total duration includes the critical, and often lengthy, phases of heating, pressurizing, cooling, and depressurizing the chamber.

The total time to use an autoclave is not a single, fixed number. It is a variable that depends entirely on the size, density, and type of materials you are sterilizing, as well as the specific cycle you select.

The Four Phases of an Autoclave Cycle

To understand why the total time varies so much, you must understand that the process is more than just "cooking" the items. The full cycle consists of four distinct phases, each contributing to the total duration.

Phase 1: Heat-Up and Purge

This initial phase involves heating the water in the autoclave to generate steam. The steam then displaces the cooler, heavier air in the chamber, pushing it out through a drain. This step is crucial because trapped air can create cold spots and prevent effective sterilization. The time this takes depends on the size of the autoclave and the initial temperature of the chamber.

Phase 2: Sterilization (or Exposure)

This is the phase most people think of. Once all air is purged and the chamber reaches the target temperature and pressure (typically 121°C and 15 psi), the sterilization timer begins.

The duration of this hold time is determined by the load. A standard time for sterilizing lab equipment or media is 15-20 minutes, but this can be much longer for denser loads.

Phase 3: Cool-Down and Exhaust

After the sterilization hold time is complete, the chamber must cool down and depressurize. The steam is slowly vented from the chamber, allowing the pressure to return to a safe, ambient level.

This is often the longest and most critical phase, especially when sterilizing liquids. Releasing pressure too quickly will cause liquids to boil over violently.

Phase 4: Drying

For cycles involving non-liquid items like glassware, instruments, or wrapped packs, a post-sterilization drying phase is often included. This phase uses a vacuum and heat to remove residual moisture, adding extra time to the total cycle.

Key Factors That Determine Cycle Time

The specific contents of your load are the single biggest factor influencing the total run time.

Load Type: Liquids vs. Solids

Sterilizing liquids takes significantly longer than sterilizing solid instruments or glassware. This is entirely due to the slow, careful cool-down phase required to prevent boil-over. A liquid cycle can easily add 30 minutes or more to the total time compared to a standard gravity cycle for dry goods.

Load Size and Density

A large, dense load takes longer for steam to penetrate effectively. A tightly packed bag of biological waste or a large flask of media will require a longer sterilization hold time to ensure the center of the load reaches the target temperature. A few small, unwrapped glass beakers will be much faster.

Autoclave Type and Cycle

Modern autoclaves often have specialized cycles. A pre-vacuum (prevac) cycle actively pumps all the air out of the chamber before introducing steam. This process is much faster and more efficient at steam penetration than a standard gravity displacement cycle, shortening the overall time considerably.

Understanding the Trade-offs: Speed vs. Efficacy

Attempting to shorten an autoclave cycle without understanding the principles behind it can lead to failed sterilization and significant safety risks.

The Danger of Rushing the Cool-Down

Never attempt to manually vent or open an autoclave to speed up cooling, especially with liquids. This can lead to explosive boiling, shattered glassware, and severe burns. The programmed slow-venting cycle is a critical safety feature.

Ensuring Complete Sterilization

The sterilization hold time is calculated to ensure a complete kill of all microorganisms. Reducing this time to save a few minutes is a false economy; if sterilization is incomplete, the entire run is wasted, and your research or process is compromised.

Estimating the Time for Your Specific Load

Use the following guidelines to better predict how long your autoclave run will take.

- If your primary focus is sterilizing liquids (e.g., media): Plan for a longer cycle (often 90+ minutes) due to the slow, controlled cooling phase required to prevent boil-over.

- If your primary focus is sterilizing solid, unwrapped items (e.g., glassware, instruments): You can often use a faster gravity cycle, with total times closer to 60 minutes.

- If your primary focus is sterilizing dense loads (e.g., biohazard waste): Increase the sterilization hold time to ensure full steam penetration, which will extend the total cycle duration.

- If your primary focus is speed and high throughput: A pre-vacuum (prevac) autoclave is the ideal choice, as its active air removal significantly shortens the initial heat-up phase and overall cycle time.

Understanding these core factors allows you to move from simply waiting for the autoclave to strategically planning your sterilization workflow.

Summary Table:

| Factor | Impact on Cycle Time | Example |

|---|---|---|

| Load Type | Liquids require slow cooling | Liquid cycle: 90+ min; Solid cycle: ~60 min |

| Load Density | Dense loads need longer sterilization | Biohazard waste vs. empty glassware |

| Autoclave Type | Pre-vacuum cycles are faster | Pre-vacuum vs. gravity displacement |

| Cycle Phase | Heating and cooling are lengthy | Sterilization hold: 15-30 min; Full cycle: 60-90 min |

Optimize Your Lab's Sterilization Workflow with KINTEK

Are you losing valuable research time waiting for autoclave cycles? Choosing the right autoclave for your specific needs—whether for delicate liquids, high-throughput solids, or dense biohazard waste—can dramatically improve your lab's efficiency and safety.

KINTEK specializes in providing reliable laboratory autoclaves and consumables tailored to your unique requirements. Our experts will help you select the ideal equipment to ensure effective sterilization while minimizing cycle times.

Contact us today to discuss how we can enhance your lab's productivity and safety.

Visual Guide

Related Products

- Portable High Pressure Laboratory Autoclave Steam Sterilizer for Lab Use

- Laboratory Sterilizer Lab Autoclave Pulsating Vacuum Desktop Steam Sterilizer

- Laboratory High Pressure Steam Sterilizer Vertical Autoclave for Lab Department

- Laboratory Sterilizer Lab Autoclave Herbal Powder Sterilization Machine for Plant

- Desktop Fast Laboratory Autoclave Sterilizer 20L 24L for Lab Use

People Also Ask

- What is an autoclave laboratory equipment? The Ultimate Guide to Steam Sterilization

- What is the temperature of autoclave in microbiology lab? Achieve Sterile Conditions with 121°C

- How are autoclaves checked and maintained? Ensure Sterilization Safety and Compliance

- What are the chambers of the autoclave? Understanding Single-Wall vs. Jacketed Designs

- What are the specifications of a laboratory autoclave? A Guide to Key Features for Safe Sterilization