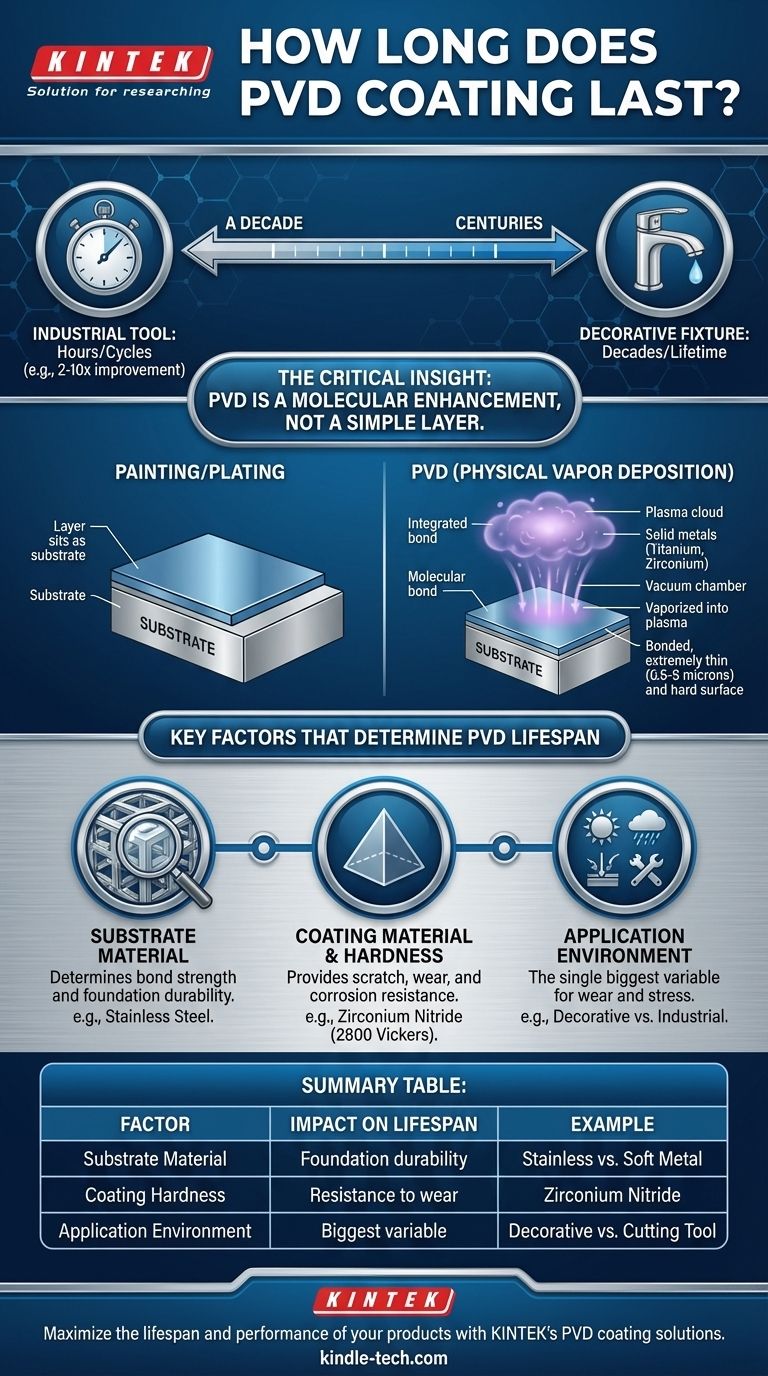

The lifespan of a Physical Vapor Deposition (PVD) coating ranges from a decade to potentially centuries, but this wide range depends entirely on the application. For a high-wear industrial tool, its life might be measured in hours of improved performance, while for a decorative fixture, it can easily outlast the object it coats.

The critical insight is that PVD is not a simple layer of paint; it's a molecular enhancement of a surface. Therefore, its longevity is not a property of the coating alone but a function of the entire system: the base material, the coating type, its thickness, and the environment it must endure.

How PVD Creates a Superior Bond

Physical Vapor Deposition is not a wet application process. It takes place in a vacuum where solid metals, such as titanium or zirconium, are vaporized into a plasma.

A Molecular-Level Change

This metal plasma is then deposited onto the target object (the "substrate"), forming a new, bonded surface at the molecular level. This is fundamentally different from painting or plating, which are just layers sitting on top of the surface.

An Extremely Thin, Hard Finish

The resulting finish is exceptionally thin, typically between 0.5 and 5 microns. Despite this, it is incredibly hard and highly resistant to corrosion and oxidation, directly contributing to its durability.

The Key Factors That Determine PVD Lifespan

The "10 to 100+ years" answer is only meaningful when you analyze the specific factors at play for your application.

The Substrate Material

The PVD coating's performance is inseparable from the material it is applied to. A strong, well-prepared substrate is essential for a long-lasting bond.

For example, a Titanium Nitride (TiN) coating applied to a titanium alloy can increase its fatigue limit and endurance, making the entire part more durable.

Coating Material and Hardness

Different coating materials provide different properties. Zirconium Nitride (ZrN), often used for "Lifetime Brass" finishes, has an immense hardness of 2800 Vickers.

This extreme hardness is what provides the exceptional scratch and wear resistance that allows a faucet or door handle to look new for decades.

Application and Wear Conditions

The single biggest variable is the environment. A PVD-coated watch will face far less stress than a PVD-coated cutting tool.

For industrial tools, the lifespan isn't measured in years but in performance improvement. A PVD-coated drill bit might see its functional life increase by 2 to 10 times compared to an uncoated one, translating to more hours of use under extreme friction and heat.

Understanding the Limitations

While incredibly effective, PVD is not a universal solution. Understanding its limitations is key to using it successfully.

The Coating is Only as Good as the Substrate

PVD cannot fix a poor-quality base material. If the substrate is soft, weak, or improperly cleaned, the coating cannot bond effectively and may fail prematurely. The strength of the final product depends on the foundation.

Bond Strength is Paramount

The durability of the coating relies entirely on the bond between the coating and the substrate. The PVD process is designed to create a very strong, integrated bond, but any failure in that process will compromise the lifespan.

Making the Right Choice for Your Goal

To determine how long a PVD coating will last for you, you must first define your primary objective.

- If your primary focus is decorative durability (e.g., faucets, hardware, watches): A well-applied coating on a quality substrate like stainless steel can be considered semi-permanent, easily lasting for decades with minimal wear.

- If your primary focus is industrial wear resistance (e.g., cutting tools, dies): The lifespan is measured in a dramatic extension of operational life—often a 200-1000% improvement—under high-stress conditions.

- If your primary focus is corrosion resistance: The coating forms a chemically non-reactive barrier that can protect the underlying substrate from oxidation and corrosion for many years, even in harsh environments.

Ultimately, viewing PVD not as a simple surface finish but as a fundamental upgrade to the substrate itself is the key to achieving exceptional and predictable longevity.

Summary Table:

| Factor | Impact on Lifespan | Example |

|---|---|---|

| Substrate Material | Determines bond strength and foundation durability. | Coating on stainless steel vs. soft metal. |

| Coating Type/Hardness | Provides scratch, wear, and corrosion resistance. | Zirconium Nitride (2800 Vickers hardness). |

| Application Environment | The single biggest variable for wear and stress. | Decorative fixture vs. industrial cutting tool. |

| Coating Thickness | Affects overall durability and resistance to wear. | Typically 0.5 to 5 microns. |

Maximize the lifespan and performance of your products with KINTEK's PVD coating solutions.

Whether you are developing durable decorative hardware, high-performance industrial tools, or components requiring superior corrosion resistance, the right PVD coating is a critical investment. The longevity of your coating depends on a perfect match between your substrate, the coating material, and the application process.

KINTEK specializes in advanced lab equipment and consumables for surface science and materials testing. Our expertise can help you select and apply the ideal PVD coating to ensure your product meets its durability goals, whether that's decades of aesthetic appeal or a 10x improvement in tool life.

Let's enhance your product's durability together. Contact our experts today to discuss your specific application and requirements.

Visual Guide

Related Products

- Graphite Vacuum Continuous Graphitization Furnace

- High Pressure Laboratory Vacuum Tube Furnace Quartz Tubular Furnace

- Custom PTFE Teflon Parts Manufacturer for PTFE Tweezers

- 2200 ℃ Graphite Vacuum Heat Treat Furnace

- Vacuum Heat Treat and Molybdenum Wire Sintering Furnace for Vacuum Sintering

People Also Ask

- Is graphite good for high temperature? Unlock Its Full Potential in Controlled Atmospheres

- Is graphite affected by heat? Discover Its Remarkable Strength and Stability at High Temperatures

- Can graphite withstand high-temperature? Maximizing Performance in Controlled Atmospheres

- How well does graphite transfer heat? Unlock Superior Thermal Management for Your Electronics

- What is the temperature resistance of graphite? Unlocking Its High-Temp Potential in Your Lab