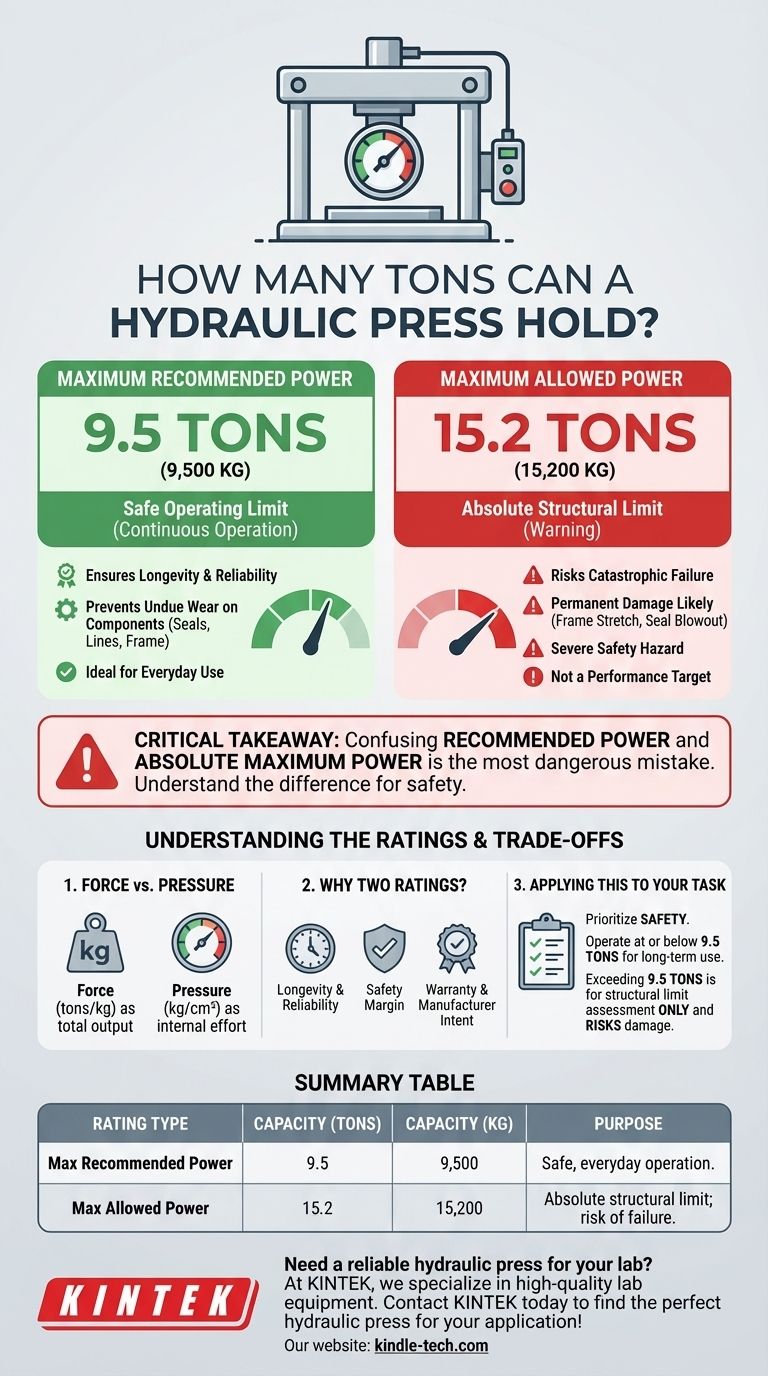

For this specific hydraulic press, its maximum recommended capacity is 9.5 tons (9,500 kg), which is the safe limit for continuous operation. While it has an absolute maximum allowed power of 15.2 tons (15,200 kg), exceeding the recommended limit risks catastrophic failure and is strongly advised against.

The most critical takeaway is that a hydraulic press has two key ratings: a recommended power for safe, everyday use and an absolute maximum power that represents a structural and safety limit. Confusing these two values is the most common and dangerous mistake an operator can make.

Deconstructing Hydraulic Press Ratings

To properly understand the capabilities of any press, you must look beyond a single number. The specifications tell a story about performance, safety, and operational limits.

Maximum Recommended Power: The Safe Operating Limit

This is the most important number for any operator. For the press in question, this value is 9,500 kg, or 9.5 metric tons.

This figure represents the maximum force the press can safely and repeatedly exert without causing undue wear on its components, such as seals, hydraulic lines, and the frame itself. Operating at or below this limit ensures the machine's longevity and reliability.

Maximum Allowed Power: The Absolute Structural Limit

The specifications also list a maximum allowed power of 15,200 kg, or 15.2 metric tons. This is not a performance target; it is a warning.

This number indicates the absolute peak force the press can withstand before a critical failure is likely. Pushing a press to this limit, even once, can cause permanent damage, stretch the frame, blow out hydraulic seals, and create a severe safety hazard.

Force vs. Pressure: A Critical Distinction

You will notice values like 250 kg/cm² and 400 kg/cm² in the specifications. It is crucial to understand that this is pressure, not force.

Force (measured in tons or kg) is the total output push the press delivers. Pressure (measured in kg/cm² or psi) is the amount of force applied over a specific area inside the hydraulic system. Think of it as the internal effort required to generate the external force.

Understanding the Trade-offs: Why Two Ratings?

The distinction between recommended and maximum power exists for critical reasons related to safety, equipment life, and reliability.

Longevity and Reliability

Consistently operating near the absolute maximum limit introduces metal fatigue and accelerates wear on every component. The recommended power is set to provide a buffer, ensuring the press can perform its job for years without premature failure.

Safety and Predictability

The gap between the 9.5-ton recommended limit and the 15.2-ton absolute limit is your safety margin. Hydraulic systems operate under immense pressure. Exceeding the recommended power eats into that safety margin, making failure less predictable and far more dangerous.

Warranty and Manufacturer Intent

Operating a press beyond its recommended power will almost certainly void its warranty. Manufacturers provide the maximum allowed rating to inform you of the physical breaking point, not to suggest it as a usable capacity. The recommended power is the true performance specification.

How to Apply This to Your Task

Your choice of operating pressure should always be guided by safety and the requirements of the job, not by the absolute limit of the machine.

- If your primary focus is safety and long-term use: Always operate at or below the maximum recommended power of 9.5 tons.

- If you are assessing structural limits for a high-risk operation: The press is theoretically capable of 15.2 tons, but this risks permanent damage and is not advised for any standard procedure.

Ultimately, understanding the difference between recommended and maximum limits is the key to using any hydraulic press safely and effectively.

Summary Table:

| Rating Type | Capacity (Tons) | Capacity (kg) | Purpose |

|---|---|---|---|

| Maximum Recommended Power | 9.5 tons | 9,500 kg | Safe, everyday operation for long-term reliability. |

| Maximum Allowed Power | 15.2 tons | 15,200 kg | Absolute structural limit; risking catastrophic failure. |

Need a reliable hydraulic press you can trust for your lab's demanding applications?

At KINTEK, we specialize in high-quality lab equipment, including hydraulic presses built for precision, safety, and durability. Our experts can help you select the right press with clear, safe operating guidelines tailored to your specific laboratory needs—ensuring your team works efficiently and safely.

Contact KINTEK today to find the perfect hydraulic press for your application!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Automatic Laboratory Hydraulic Press for XRF & KBR Pellet Press

- Automatic High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Manual High Temperature Heated Hydraulic Press Machine with Heated Plates for Lab

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

People Also Ask

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- What is the use of KBr? Master Sample Prep for Accurate IR Spectroscopy

- Are hydraulic presses powered by water? Discover the critical role of hydraulic oil.

- How does a laboratory hydraulic press improve XRF accuracy for catalyst samples? Enhance Precision & Signal Stability

- What is the advantage of KBr? Unmatched IR Transparency for Precise Spectroscopy