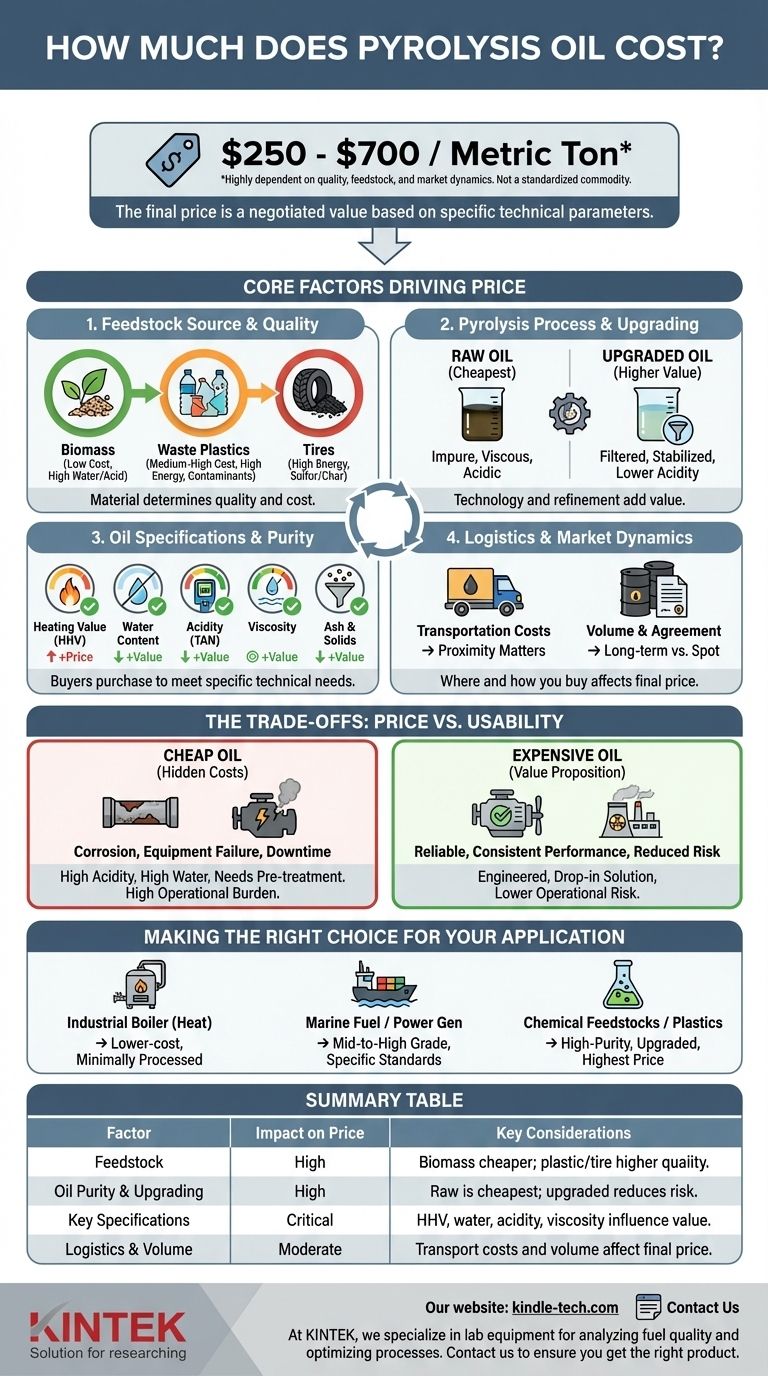

Determining the cost of pyrolysis oil requires looking beyond a single market price. While a general range is between $250 to $700 per metric ton, this figure is highly dependent on oil quality, feedstock source, and market dynamics. The final price is less a commodity quote and more a negotiated value based on specific technical parameters.

The central takeaway is that pyrolysis oil is not a standardized product like crude oil. Its price is a direct reflection of its quality, which is determined by the raw materials used and the sophistication of the production process. A low price often indicates significant downstream challenges.

The Core Factors Driving Pyrolysis Oil Price

The wide price range exists because "pyrolysis oil" is a broad term for a complex liquid. Four key factors dictate its market value.

### Feedstock Source and Quality

The material you put into the pyrolysis reactor is the single greatest determinant of the resulting oil's quality and cost.

- Biomass (e.g., wood, agricultural residue): This oil, often called bio-oil or bio-crude, is typically acidic, has high water content (15-30%), and contains oxygenates, making it corrosive and unstable. It is often at the lower end of the price spectrum.

- Waste Plastics (e.g., mixed polyolefins): Plastic-derived oil has a much higher energy content, similar to diesel, and lacks the high water and oxygen of bio-oil. However, contaminants like PVC can introduce chlorine, which must be removed, impacting price.

- End-of-Life Tires: Tire-derived oil has high energy value but also high sulfur content and a significant carbon black component (char), which requires post-processing. Its price is often between biomass and high-purity plastic oils.

### Pyrolysis Process and Upgrading

The technology used to create and refine the oil has a direct impact on its value.

Raw or "crude" pyrolysis oil is the direct output from the reactor. It is often a dark, viscous liquid with impurities, water, and acidic compounds. This is the cheapest form.

Upgraded pyrolysis oil has undergone additional processing steps like filtration, dewatering, or hydrotreating to remove impurities, reduce acidity, and improve stability. Each upgrading step adds cost but creates a significantly higher-value product that can be used in more demanding applications.

### Oil Specifications and Purity

Buyers purchase pyrolysis oil to meet a specific technical need. Key specifications that drive price include:

- Heating Value (HHV): Higher energy content commands a higher price.

- Water Content: Lower water content is more valuable, as water provides no energy and can cause combustion problems.

- Acidity (TAN - Total Acid Number): Low acidity is critical to prevent corrosion in storage tanks, pipes, and engines.

- Viscosity: Buyers need a specific viscosity range for their pumps and injectors to function correctly.

- Ash and Solids Content: Impurities like char and inorganic materials can clog equipment and must be minimal for most uses.

### Logistics and Market Dynamics

Where and how you buy the oil matters.

Transportation costs are a major factor. Pyrolysis oil is dense and often requires specialized transport, so proximity to the production plant is key.

Volume also dictates price. A large, long-term offtake agreement will secure a lower price per ton than a small, one-time "spot" purchase. Local supply and demand, as well as the price of competing fuels like natural gas or heavy fuel oil, set the regional price ceiling.

Understanding the Trade-offs: Price vs. Usability

Choosing pyrolysis oil based on price alone is a common and costly mistake. The sticker price often hides the total cost of use.

### The Hidden Costs of "Cheap" Oil

Low-cost, non-upgraded pyrolysis oil (often from biomass or mixed waste) may seem like a bargain. However, it typically carries significant operational burdens.

Its high acidity can corrode storage tanks and fuel lines, requiring expensive, corrosion-resistant materials. High water and solid content can lead to engine or burner failure, causing downtime and costly maintenance. It often requires on-site pre-treatment before it can even be used, adding capital and operational expense.

### The Value Proposition of "Expensive" Oil

Higher-priced, upgraded pyrolysis oil is engineered for a specific purpose. It is often a "drop-in" or near-drop-in solution for replacing conventional fossil fuels.

While the initial cost per ton is higher, it reduces operational risk, eliminates the need for expensive specialized equipment, and ensures reliable, consistent performance. You are paying more for a product that works without causing secondary problems.

Making the Right Choice for Your Application

To select the right pyrolysis oil, you must align its specifications and price with your end-goal.

- If your primary focus is generating heat in a robust industrial boiler: A lower-cost, minimally processed oil may be acceptable, provided your equipment is designed to handle its corrosive and impure nature.

- If your primary focus is use as a marine fuel or power generation in engines: You will need a mid-to-high grade oil that meets specific standards for viscosity, water content, and stability to avoid catastrophic equipment failure.

- If your primary focus is creating new plastics or refined chemical feedstocks: You must procure a high-purity, upgraded oil with very low contamination levels, which will be at the highest end of the price spectrum.

Ultimately, evaluating pyrolysis oil requires you to look past the initial price and assess the total cost of ownership for your specific industrial goal.

Summary Table:

| Factor | Impact on Price | Key Considerations |

|---|---|---|

| Feedstock Source | High | Biomass oil is cheaper; plastic/tire oil is more expensive but higher quality. |

| Oil Purity & Upgrading | High | Raw oil is cheapest; upgraded oil costs more but reduces operational risks. |

| Key Specifications | Critical | Heating value, water content, acidity, and viscosity directly influence value. |

| Logistics & Volume | Moderate | Transportation costs and purchase volume (spot vs. contract) affect final price. |

Ready to find the right pyrolysis oil for your operation?

Choosing the wrong oil can lead to hidden costs from corrosion, equipment failure, and downtime. At KINTEK, we specialize in lab equipment and consumables for analyzing fuel quality and optimizing processes. Our experts can help you assess oil specifications to ensure you get a product that delivers value, not just a low sticker price.

Contact us today to discuss your specific application and get personalized support. Let KINTEK help you make an informed decision that maximizes your return on investment.

Visual Guide

Related Products

- Electric Rotary Kiln Continuous Working Small Rotary Furnace Heating Pyrolysis Plant

- Single Punch Electric Tablet Press Machine Laboratory Powder Tablet Punching TDP Tablet Press

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Multi-zone Laboratory Tube Furnace

- Laboratory Rapid Thermal Processing (RTP) Quartz Tube Furnace

People Also Ask

- What is a rotary kiln reactor? A Guide to Industrial Thermal Processing

- What are the equipment for pyrolysis laboratory? Choosing the Right Reactor for Your Research

- What are the zones in rotary kiln in cement production? Master the Core Process for High-Quality Clinker

- How does precision temperature control impact TiAl alloy sintering? Master Microstructure Development

- What is the principle of rotary kiln? Mastering Continuous Thermal Processing