The energy consumption of a filter press is highly variable, but it is overwhelmingly dictated by the feed pump, not the press itself. A complete dewatering system's energy usage can range from as low as 1-2 kWh to over 15 kWh per ton of dry solids processed, depending entirely on the slurry being dewatered and the operational goals. The press's hydraulic unit consumes a fraction of this, typically using energy only intermittently to clamp the plates.

The central takeaway is that the filter press itself is a relatively low-energy device. Approximately 90-95% of the total energy consumed in a filter press cycle is used by the feed pump to force the liquid through the filter media, making pump selection and operational parameters the most critical factors in managing energy costs.

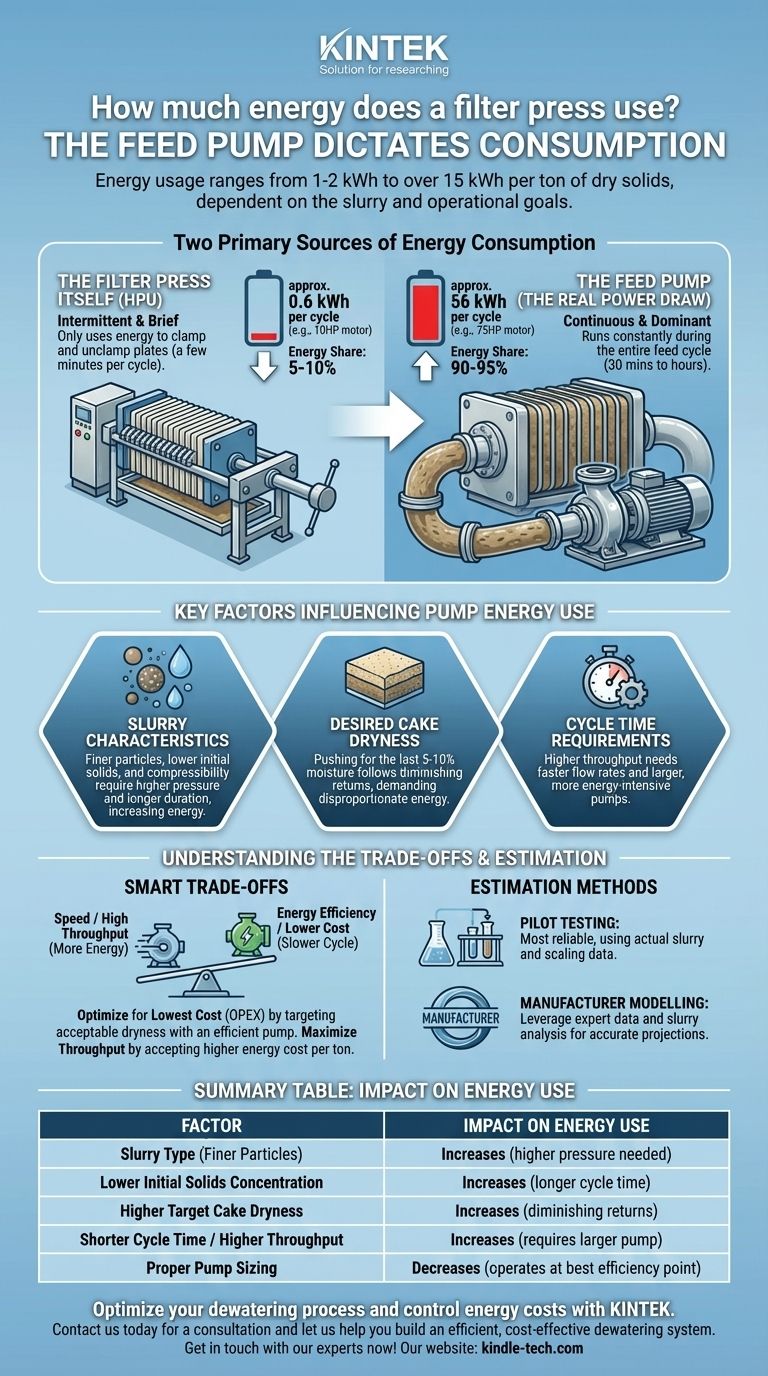

The Two Primary Sources of Energy Consumption

To understand energy use, you must separate the system into its two key components: the filter press unit and the feed pump system. They serve different functions and have vastly different energy profiles.

The Filter Press Itself (Hydraulic Power Unit)

The filter press structure requires energy for one primary task: clamping the filter plates together with immense force to create a leak-proof seal.

This is accomplished by a Hydraulic Power Unit (HPU), which consists of an electric motor driving a hydraulic pump. This system's energy consumption is intermittent and brief. It runs for only a few minutes at the beginning of a cycle to close and clamp the press, and for a few moments at the end to open it. During the long filtration (feed) and air-blow/drying stages, the HPU motor is off.

The Feed Pump (The Real Power Draw)

The feed pump is the workhorse of the dewatering process and the system's dominant energy consumer. Its job is to move the slurry from a holding tank into the filter press chambers, building pressure to overcome the resistance of the filter cloth and the forming cake of solids.

This process is continuous throughout the feed cycle, which can last from 30 minutes to several hours. The pump motor runs constantly during this period, and its energy draw is directly related to the pressure and flow rate required to dewater the slurry effectively.

Key Factors Influencing Pump Energy Use

The question is not "how much energy does a filter press use," but "how much energy is required to dewater my specific slurry to my desired specification?" The answer depends on several variables.

Slurry Characteristics

The nature of your slurry is the single most important factor. Slurries that are difficult to dewater require higher pressures for longer durations, resulting in higher energy use. Key properties include:

- Particle Size: Finer particles (clays, pigments) create a dense, less permeable filter cake that requires very high pressure to dewater. Coarse particles (sand, coal fines) form a more permeable cake, requiring less energy.

- Solids Concentration: A very dilute slurry means the pump must run longer to pump more water just to fill the press chambers before significant pressure even begins to build.

- Compressibility: Some solids deform under pressure, blinding the filter media and demanding even higher pressures to continue the flow of filtrate.

Desired Cake Dryness

Pushing out the last 5-10% of moisture from a filter cake follows a law of diminishing returns. It can require a disproportionate amount of time at maximum pressure, exponentially increasing the energy consumed per cycle. A key operational decision is determining the "good enough" point for cake dryness to balance energy cost against downstream process needs.

Cycle Time Requirements

If you need to process a high volume of slurry quickly, you will need a higher flow rate. This demands a more powerful, energy-intensive pump. A slower, more methodical dewatering cycle with a smaller pump will almost always be more energy-efficient per ton of solids processed, but it comes at the cost of lower throughput.

Understanding the Trade-offs

Optimizing a filter press operation is a balancing act. Understanding the inherent trade-offs is critical for making sound engineering and financial decisions.

Speed vs. Energy Efficiency

There is a direct trade-off between cycle time and energy efficiency. Running a pump at its maximum rated flow and pressure will achieve the fastest cycle, but pumps are often most efficient when operating at a point below their maximum output. A longer, slower feed cycle can significantly reduce the kWh consumed per ton of solids.

Cake Dryness vs. Energy Cost

Is achieving 78% dry solids critical when 75% can be reached with 30% less energy? The answer depends entirely on what happens to the cake next. If it's going to a landfill where you pay by weight, the extra dryness might be worth the energy cost. If it's being fed to a thermal dryer, the energy saved in the press might simply be spent in the dryer instead.

The Hidden Cost of Mis-Sizing

Selecting a pump is not just about meeting the maximum pressure. An undersized pump will struggle to reach the target pressure, leading to excessively long cycles and inefficient operation. Conversely, a grossly oversized pump will operate far from its best efficiency point, wasting energy even if it achieves the desired cycle time.

How to Estimate Energy Consumption

While a precise universal number is impossible, you can arrive at an accurate estimate for your specific application.

The Importance of Pilot Testing

The most reliable method for determining energy consumption is to perform a pilot test with your actual slurry. Using a small-scale filter press, an engineer can measure the required pressures and cycle times, then accurately scale that data to a full-size system and calculate the projected energy use.

Working with a Manufacturer

Provide vendors with a comprehensive slurry analysis, including particle size distribution, pH, chemical composition, and percent solids. Experienced manufacturers can use this data and their internal databases to model the dewatering process and provide a strong estimate of the required pump size and expected energy consumption.

A Rule-of-Thumb Example

To illustrate the energy disparity, consider a mid-sized system:

- Press HPU: A 10 HP motor running for 5 minutes (to close/clamp) uses about 0.6 kWh per cycle.

- Feed Pump: A 75 HP motor running for a 60-minute feed cycle uses about 56 kWh per cycle.

This simplified example shows the pump consuming nearly 100 times more energy than the press itself over a single cycle.

Making the Right Choice for Your Goal

Your operational priority will determine your approach to managing energy consumption.

- If your primary focus is minimizing operational costs (OPEX): Target the lowest acceptable cake dryness and use a properly sized pump to run at its most efficient point, even if it means slightly longer cycles.

- If your primary focus is maximizing throughput: You must accept a higher energy cost per ton, which is the price for the larger, more powerful pump needed to achieve fast cycle times.

- If your primary focus is selecting a new system: Do not skip the pilot testing phase. This data is the foundation for an accurately engineered system and will prevent costly surprises in future energy bills.

Ultimately, understanding the factors that drive energy use empowers you to control your process and align its performance with your specific business goals.

Summary Table:

| Factor | Impact on Energy Use |

|---|---|

| Slurry Type (Finer Particles) | Increases (higher pressure needed) |

| Lower Initial Solids Concentration | Increases (longer cycle time) |

| Higher Target Cake Dryness | Increases (diminishing returns) |

| Shorter Cycle Time / Higher Throughput | Increases (requires larger pump) |

| Proper Pump Sizing | Decreases (operates at best efficiency point) |

Optimize your dewatering process and control energy costs with KINTEK.

Unsure about the energy requirements for your specific slurry? Our experts can help you model the dewatering process and select the right equipment to balance throughput, cake dryness, and operational costs. We specialize in lab equipment and consumables, providing solutions tailored to your laboratory's unique needs.

Contact us today for a consultation and let us help you build an efficient, cost-effective dewatering system.

Get in touch with our experts now!

Visual Guide

Related Products

- Laboratory Hydraulic Press Split Electric Lab Pellet Press

- Hydraulic Diaphragm Lab Filter Press for Laboratory Filtration

- Laboratory Hydraulic Press Lab Pellet Press Machine for Glove Box

- Heated Hydraulic Press Machine with Heated Plates for Vacuum Box Laboratory Hot Press

- 24T 30T 60T Heated Hydraulic Press Machine with Heated Plates for Laboratory Hot Press

People Also Ask

- What is the pellet technique in IR? Master Solid Sample Preparation for Clear Spectroscopy

- How hot is a hydraulic press? Understanding the Critical Heat in Your Hydraulic System

- Why use KBr for IR? Achieve Clear, Unobstructed Spectra for Solid Samples

- What role does a laboratory hydraulic press play in the preparation of solid electrolyte pellets? Ensure Data Accuracy

- What is the pressed powder pellet method? A Guide to Accurate FTIR Sample Preparation