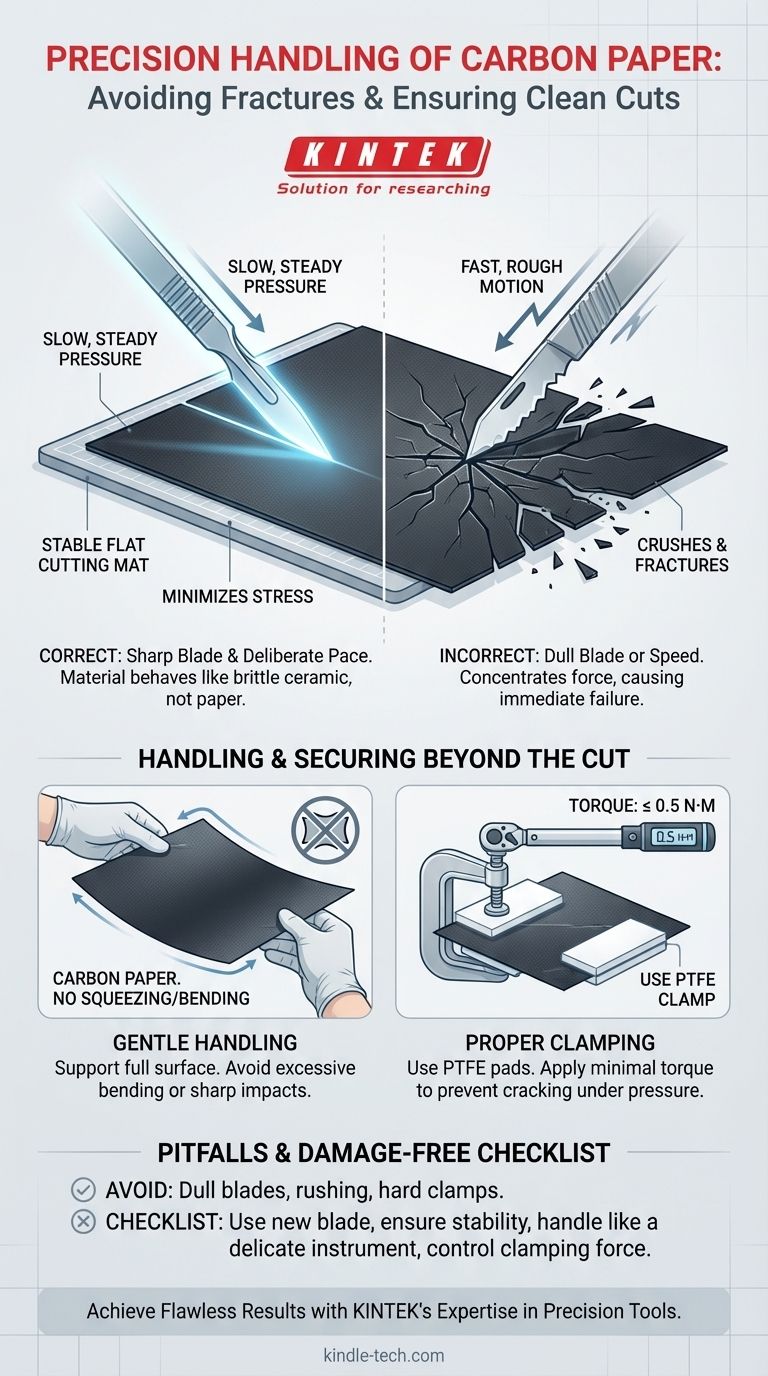

Handling carbon paper requires a delicate and precise approach. Because the material is inherently brittle and prone to fracturing, it must be cut slowly using an exceptionally sharp blade. This combination of a sharp tool and a deliberate pace minimizes the stress on the paper, preventing cracks and ensuring a clean edge.

The core challenge is not the cut itself, but managing the material's extreme brittleness. Success depends on a slow, controlled cutting method combined with careful handling at every stage to prevent fractures that would compromise its function.

The Core Principle: Managing Brittleness

Carbon paper behaves less like paper and more like a thin sheet of ceramic. It does not bend or deform under pressure; it simply fractures. Every step of the handling process must be designed to avoid applying concentrated stress.

The Essential Cutting Technique

The only reliable method is to use a sharp blade with slow, steady pressure. A sharp blade, such as a new utility knife or scalpel, slices through the material cleanly without crushing the microscopic structure. A slow cutting motion prevents heat buildup and vibrations that can initiate a fracture.

The Importance of a Stable Surface

Always place the carbon paper on a firm, flat cutting mat. A stable backing ensures the pressure you apply is distributed evenly and is used solely for the cut, preventing the sheet from bending or flexing during the process.

Handling Beyond the Cut: A Broader Perspective

A perfect cut is meaningless if the material is damaged before or after. The principles of careful handling must be applied throughout the entire workflow.

Avoiding Bending and Squeezing

Any excessive bending, squeezing, or sharp impacts can create micro-fractures that compromise the material's integrity. Handle sheets by their edges and support their full surface area whenever possible.

The Role of Clamping and Torque

When securing the material for installation or processing, use appropriate tools. A PTFE (Teflon) clamp is recommended to distribute pressure without damaging the surface. The applied torque should be minimal—no more than 0.5 N·M—to prevent cracking under pressure.

Precision is Paramount

The technical applications for this material often require precise dimensions. When cutting, ensure the exposed surface area is controlled with an error of less than 3%. This underscores the need for a careful, measured approach rather than a quick, rough cut.

Common Pitfalls to Avoid

Mistakes during handling are the primary cause of material failure. Understanding the risks is key to preventing them.

The Risk of a Dull Blade

A dull blade does not slice; it crushes and tears. This action introduces immense stress into the brittle sheet, making fractures and chipping almost inevitable. If you feel any resistance, change your blade immediately.

The Danger of Speed

Attempting to cut quickly is a false economy. A fast movement concentrates force at the blade's edge and sends vibrations through the material, which can easily cause a crack to propagate far beyond your intended cutting line.

The Consequence of Improper Securing

Clamping the carbon paper too tightly or with a hard material like metal will create stress points. This can cause the sheet to crack instantly or create invisible weaknesses that lead to failure later on.

A Checklist for Damage-Free Handling

Your approach should be dictated by the material's fragility. Use this checklist to guide your actions.

- If your primary focus is the cut itself: Use an extremely sharp blade, apply steady but light pressure, and move slowly on a stable cutting mat.

- If your primary focus is preparing for installation: Handle the material with minimal bending, and if clamping is necessary, use protective materials like PTFE and apply minimal, controlled torque.

- If your primary focus is overall material integrity: Treat the carbon paper as a delicate component from start to finish, avoiding any abrupt movements, collisions, or squeezing.

Ultimately, treating carbon paper with the meticulous care of a scientific instrument is the key to preserving its integrity for its final application.

Summary Table:

| Key Consideration | Essential Practice |

|---|---|

| Cutting Tool | Use an extremely sharp blade (e.g., scalpel, new utility knife) |

| Cutting Motion | Apply slow, steady pressure on a firm, flat cutting mat |

| Clamping | Use a PTFE clamp with minimal torque (≤ 0.5 N·M) |

| Handling | Avoid bending, squeezing, or sharp impacts; support the full sheet |

| Precision | Aim for an exposed surface area error of less than 3% |

Achieve Flawless Results with KINTEK's Expertise

Cutting delicate materials like carbon paper requires precision tools and techniques to prevent costly fractures and material waste. KINTEK specializes in providing high-quality lab equipment and consumables, including the sharp blades and stable surfaces essential for handling brittle materials.

Let our experts help you optimize your workflow and protect your materials. Contact KINTEK today to discuss your specific laboratory needs and discover how our solutions can enhance your precision and efficiency.

Visual Guide

Related Products

- Professional Cutting Tools for Carbon Paper Cloth Diaphragm Copper Aluminum Foil and More

- Glassy Carbon Sheet RVC for Electrochemical Experiments

- Hydrophilic Carbon Paper TGPH060 for Battery Lab Applications

- Silicon Carbide (SIC) Ceramic Sheet Wear-Resistant Engineering Advanced Fine Ceramics

- Isostatic Molding Pressing Molds for Lab

People Also Ask

- What precautions should be taken when cutting carbon cloth? Avoid Short Circuits and Ensure Device Safety

- What are diamond coated tools used for? Conquer Abrasive Materials with Superior Tool Life

- What are the correct storage conditions for an RVC sheet? Ensure Long-Term Performance and Integrity

- Can sintered metal be machined? Master the Techniques for Porous Materials

- What industrial uses are there for diamonds? Unlock High-Performance Applications