When cutting carbon cloth, the most critical precautions are to prevent the creation of frayed edges and to manage the resulting loose fibers. These stray, conductive fibers can easily cause electrical short circuits in sensitive applications, leading to component failure. Securing the cut edges with a suitable adhesive is a common and effective post-cutting step.

The challenge of cutting carbon cloth is not merely dimensional accuracy; it is about preserving the material's electrical integrity. Every cut must be treated as a controlled process to prevent loose, conductive fibers from compromising the safety and performance of the final device.

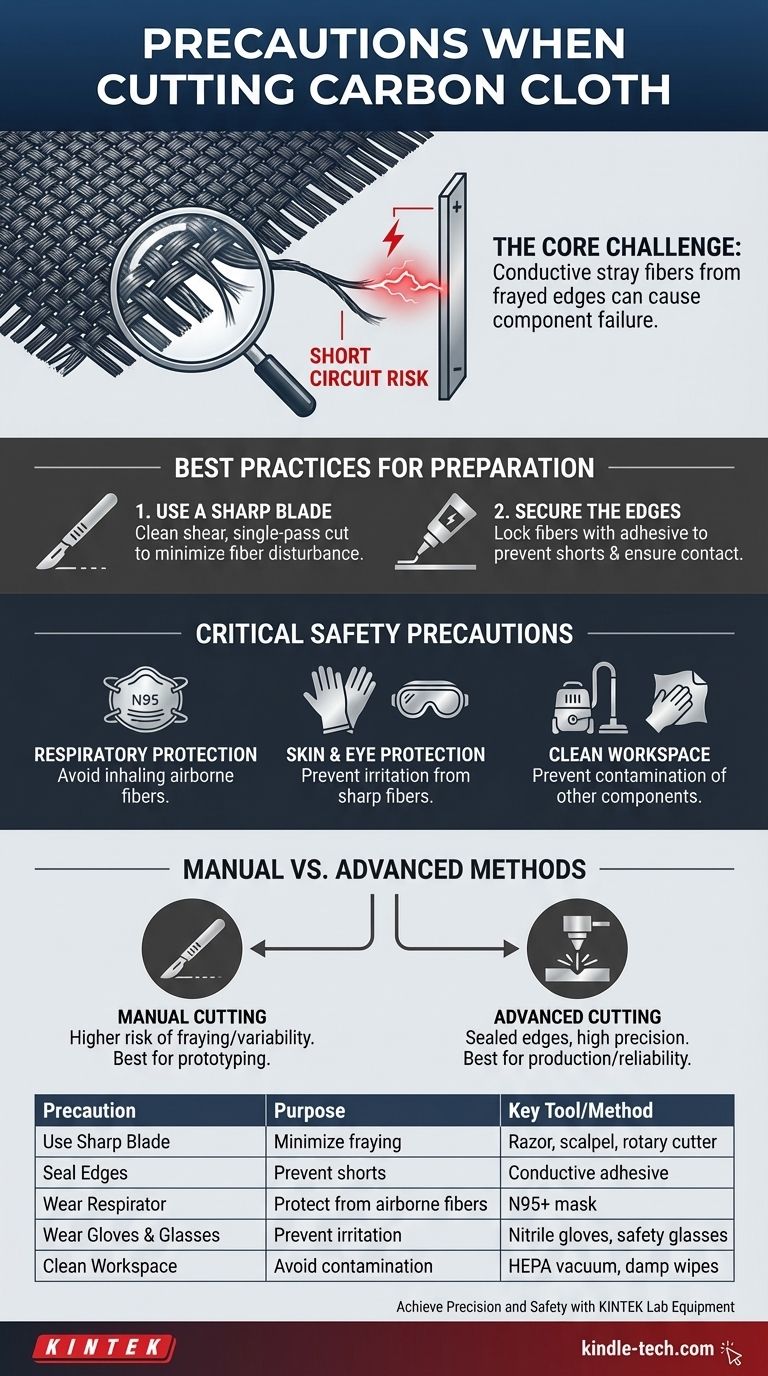

The Core Challenge: Conductivity and Fraying

Why Fraying is a Critical Risk

Carbon cloth is composed of woven or non-woven carbon fibers. These fibers are inherently electrically conductive, which is often the primary reason for their use in applications like fuel cells, batteries, and supercapacitors.

When you cut the cloth, you inevitably sever these fibers, creating loose strands at the edge.

How Frayed Fibers Cause Short Circuits

In an electrochemical device, components like the anode and cathode are separated by a non-conductive membrane. If a single loose carbon fiber from the electrode edge detaches and bridges this gap, it creates a direct, low-resistance path for electricity.

This internal short circuit can cause immediate device failure, catastrophic overheating, or a significant drop in performance.

Best Practices for Cutting and Preparation

Use an Extremely Sharp Blade

The goal is to shear the fibers cleanly rather than crush or tear them. Scissors are often a poor choice as they can squeeze the weave and exacerbate fraying.

Use a fresh razor blade, scalpel, or a rotary cutter against a firm cutting mat. This allows for a clean, single-pass cut that minimizes fiber disturbance.

Secure the Edges After Cutting

As noted in best practices, sealing the edges is a vital step to lock loose fibers in place.

Using a conductive glue or a compatible polymer binder along the cut edge is a standard method. This not only prevents fraying but can also help maintain good electrical contact along the perimeter of the electrode. The choice of adhesive must be chemically inert in your specific application's environment (e.g., resistant to the electrolyte).

Critical Safety Precautions to Observe

Respiratory Protection

Cutting carbon cloth can release microscopic, airborne fiber fragments. Inhaling these particles can be a respiratory irritant and a potential long-term health hazard.

Always wear a well-fitting particulate respirator (e.g., N95 or higher) when cutting or handling the material in a way that could generate dust.

Skin and Eye Protection

The small, stiff fibers can easily embed in or irritate the skin. Always wear nitrile or other suitable gloves.

Safety glasses are mandatory to protect your eyes from any airborne particles generated during the cutting process.

Maintain a Clean Workspace

Conductive carbon fibers can contaminate other sensitive components, experiments, or electronics in your lab. Dedicate a specific, clean area for cutting and clean it thoroughly with a HEPA-filtered vacuum or damp wipe-down after use.

Understanding the Trade-offs

Edge Sealing Reduces Active Area

Applying glue or a binder to the edge of the cloth effectively "deadens" that portion, meaning it can no longer participate in the electrochemical reaction. You must account for this reduction in active surface area during the design phase to ensure your component meets its performance targets.

Manual Cutting vs. Advanced Methods

While manual cutting with a blade is accessible, it carries the highest risk of operator-dependent variability and fraying.

For high precision and repeatability, methods like die-cutting or laser cutting are superior. Laser cutting, in particular, can thermally seal the edge as it cuts, providing a perfectly clean and stable result, though it requires specialized equipment.

Making the Right Choice for Your Application

- If your primary focus is rapid prototyping or initial testing: Careful cutting with a fresh razor blade may be sufficient, but be extremely vigilant for potential short circuits during device assembly and operation.

- If your primary focus is a reliable, long-life device: A post-cut edge-sealing step using a chemically compatible conductive adhesive is essential for ensuring stability and safety.

- If your primary focus is high-volume production or ultimate precision: Investing in an automated process like die-cutting or laser cutting will yield the most consistent and reliable results.

Ultimately, treating carbon cloth preparation with meticulous care is the foundational step toward building a safe and effective final device.

Summary Table:

| Precaution | Purpose | Key Tool/Method |

|---|---|---|

| Use Sharp Blade | Clean cut to minimize fraying | Razor blade, scalpel, rotary cutter |

| Seal Edges | Lock fibers to prevent shorts | Conductive adhesive or polymer binder |

| Wear Respirator | Protect from airborne fibers | N95 or higher particulate mask |

| Wear Gloves & Glasses | Prevent skin/eye irritation | Nitrile gloves, safety glasses |

| Clean Workspace | Avoid contamination of other components | HEPA vacuum, damp wipes |

Achieve Precision and Safety with KINTEK Lab Equipment

Cutting carbon cloth requires precision tools and a meticulous approach to prevent costly failures. KINTEK specializes in supplying high-quality lab equipment and consumables—including precision cutting tools and compatible adhesives—to help your laboratory maintain material integrity and operational safety.

Let us support your research in fuel cells, batteries, and supercapacitors with reliable solutions tailored to your needs. Contact KINTEK today to discuss how our products can enhance your workflow and protect your devices from short circuits.

Visual Guide

Related Products

- Professional Cutting Tools for Carbon Paper Cloth Diaphragm Copper Aluminum Foil and More

- Three-dimensional electromagnetic sieving instrument

- CVD Diamond Cutting Tool Blanks for Precision Machining

- Automatic Laboratory Heat Press Machine

- Precision Wire Saw Laboratory Cutting Machine with 800mm x 800mm Workbench for Diamond Single Wire Circular Small Cutting

People Also Ask

- What is a substitute for tungsten carbide? Explore Advanced Materials for Superior Performance

- Can sintered metal be machined? Master the Techniques for Porous Materials

- What industrial uses are there for diamonds? Unlock High-Performance Applications

- What are diamond coated tools used for? Conquer Abrasive Materials with Superior Tool Life

- What are the specific uses of a precision disc cutter in the assembly of solid-state batteries? Ensure Burr-Free Accuracy