To choose the right induction furnace, you must look beyond the price tag and evaluate four critical factors: the furnace's capacity and size, the power supply's rating (kW), the operating frequency (Hz), and the type of material you intend to melt. These parameters directly determine the furnace's melt rate, energy efficiency, and suitability for your specific production requirements.

The optimal induction furnace is not the most powerful or the largest, but the one whose technical specifications are most precisely aligned with your operational scale, material type, and long-term energy costs. This is a decision about total cost of ownership, not just initial purchase price.

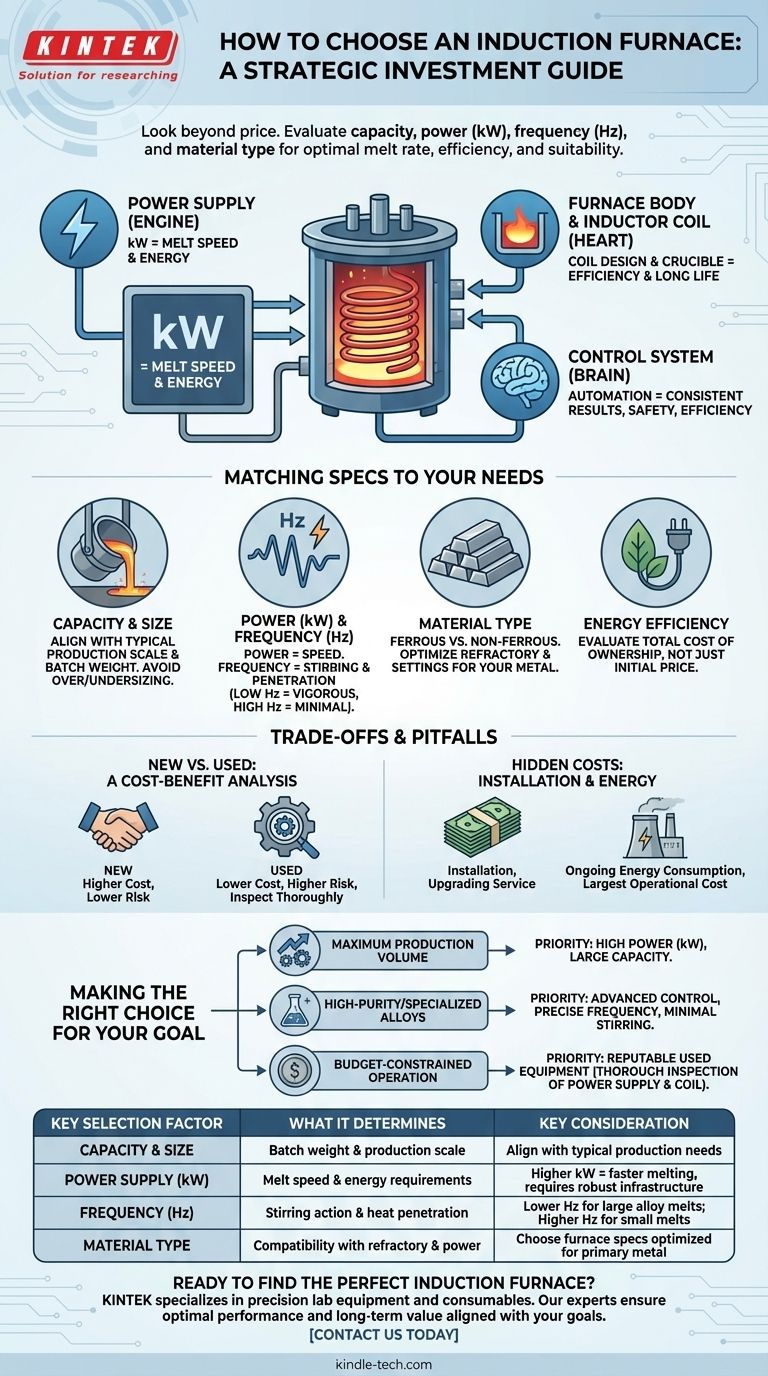

Deconstructing the Core Components

Understanding the function of each primary component is the first step in making an informed decision. The furnace is a system where each part plays a critical role in performance and reliability.

The Power Supply: The Engine of the Furnace

The power supply converts mains electricity into the specific voltage and frequency needed to generate the magnetic field for induction heating. Its power rating, measured in kilowatts (kW), is the single biggest factor determining how fast you can melt metal.

A higher kilowatt rating translates directly to a faster melt rate, but also requires more robust electrical infrastructure and results in higher energy consumption.

The Furnace Body and Inductor Coil: The Heart of the Operation

The furnace body contains the crucible (which holds the metal) and the inductor coil. The coil, made of copper tubing, is where the electric current flows to create the powerful magnetic field.

The design of this coil and its proximity to the metal charge are crucial for energy efficiency. The crucible's lining material (refractory) must also be chosen carefully based on the type of metal being melted to prevent chemical reactions and ensure a long service life.

The Control System: The Brains of the System

Modern induction furnaces feature sophisticated control systems that manage power levels, monitor temperatures, and ensure operational safety.

Advanced controls can automate melt cycles, leading to more consistent metallurgical results, improved energy efficiency, and reduced reliance on operator skill.

Matching Furnace Specifications to Your Production Needs

Once you understand the components, you can begin to match them to your specific operational goals. The key is to quantify your requirements before you start comparing models.

Calculating Required Capacity and Size

Your required furnace capacity is dictated by your production scale. Consider the weight of metal you need to process per batch and the number of batches you plan to run per day.

Always choose a size that aligns with your typical production needs. An oversized furnace is inefficient to run for smaller batches, while an undersized one will create a production bottleneck.

Understanding Power (kW) and Frequency (Hz)

Power (kW) determines your melt speed, but frequency (Hz) influences the "stirring" action within the molten metal and the depth of heat penetration.

Lower frequencies create more vigorous stirring, which is ideal for homogenizing large melts of common alloys. Higher frequencies are better for smaller melts or for metals where minimal stirring is desired to prevent gas pickup or oxidation.

Material-Specific Considerations

The type of metal you are melting has a significant impact on furnace selection. Ferrous metals like iron and steel have different magnetic properties and melting points than non-ferrous metals like aluminum or copper.

Ensure the furnace's power supply, frequency, and refractory lining are optimized for the primary materials you will be processing.

Understanding the Trade-offs and Pitfalls

A successful purchase involves looking beyond the brochure and considering the practical realities and potential hidden costs.

New vs. Used: A Cost-Benefit Analysis

A used furnace can offer significant upfront savings, but it comes with risks. If considering used equipment, a thorough inspection is non-negotiable.

Inquire about all previous repairs and faults, and pay special attention to the condition of the power supply, capacitors, and inductor coil. Avoid purchasing a worn-out unit based on a low price, as replacement component costs can quickly erase any initial savings.

The Hidden Costs: Installation and Energy Consumption

The purchase price is only part of the total cost. You must also factor in the cost of installation, which can include foundational work and upgrading your facility's electrical service and cooling water systems.

Furthermore, ongoing energy consumption will be your largest operational cost. An efficient, modern power supply may cost more initially but can save you substantial amounts of money over the furnace's lifetime.

Scope of Supply: What's Included?

When comparing price quotes, verify the exact scope of supply. Clarify whether the price includes essential auxiliary equipment like the water cooling system, crucible, hydraulic tilting system, and control panel.

Also, ask about the costs of shipping, installation supervision, operator training, and ongoing technical support.

Making the Right Choice for Your Goal

Your final decision should be guided by your primary business objective.

- If your primary focus is maximum production volume: Prioritize a furnace with a high power (kW) rating and a large capacity that matches your desired output.

- If your primary focus is high-purity or specialized alloys: Select a furnace with an advanced control system and the appropriate frequency for precise temperature management and minimal stirring.

- If your primary focus is a budget-constrained operation: Carefully evaluate reputable used equipment, focusing your inspection on the health of the power supply and inductor coil, and factor in potential refurbishment costs.

Choosing the right induction furnace is a strategic investment in your production capability that pays dividends for years to come.

Summary Table:

| Key Selection Factor | What It Determines | Key Consideration |

|---|---|---|

| Capacity & Size | Batch weight and production scale | Align with typical production needs to avoid bottlenecks or inefficiency. |

| Power Supply (kW) | Melt speed and energy requirements | Higher kW = faster melting, but requires robust electrical infrastructure. |

| Frequency (Hz) | Stirring action and heat penetration depth | Lower Hz for large alloy melts; higher Hz for small melts or sensitive metals. |

| Material Type | Compatibility with refractory lining and power settings | Choose furnace specs optimized for your primary metal (ferrous vs. non-ferrous). |

Ready to find the perfect induction furnace for your lab or production line? KINTEK specializes in lab equipment and consumables, serving laboratory needs with precision and reliability. Our experts will help you select a furnace that aligns with your operational goals, material type, and budget—ensuring optimal performance and long-term value. Contact us today for a personalized consultation!

Visual Guide

Related Products

- Non Consumable Vacuum Arc Induction Melting Furnace

- 600T Vacuum Induction Hot Press Furnace for Heat Treat and Sintering

- 1700℃ Laboratory High Temperature Tube Furnace with Alumina Tube

- 1800℃ Muffle Oven Furnace for Laboratory

- Ultra-High Temperature Graphite Vacuum Graphitization Furnace

People Also Ask

- What are the advantages and disadvantages of brazing? A Guide to Strong, Clean Metal Joining

- What is AC frame? Decoding the Two Meanings in Wi-Fi and Video

- What is the difference between VAR and VIM? Legacy Vimscript Variables vs. Modern Neovim API

- What is the role of a laboratory vacuum arc remelting furnace? Mastering High-Entropy Alloy Synthesis

- How does vacuum arc melting equipment facilitate Ti-Cr-Al-Nb alloy prep? Precision High-Temp Melting Explained