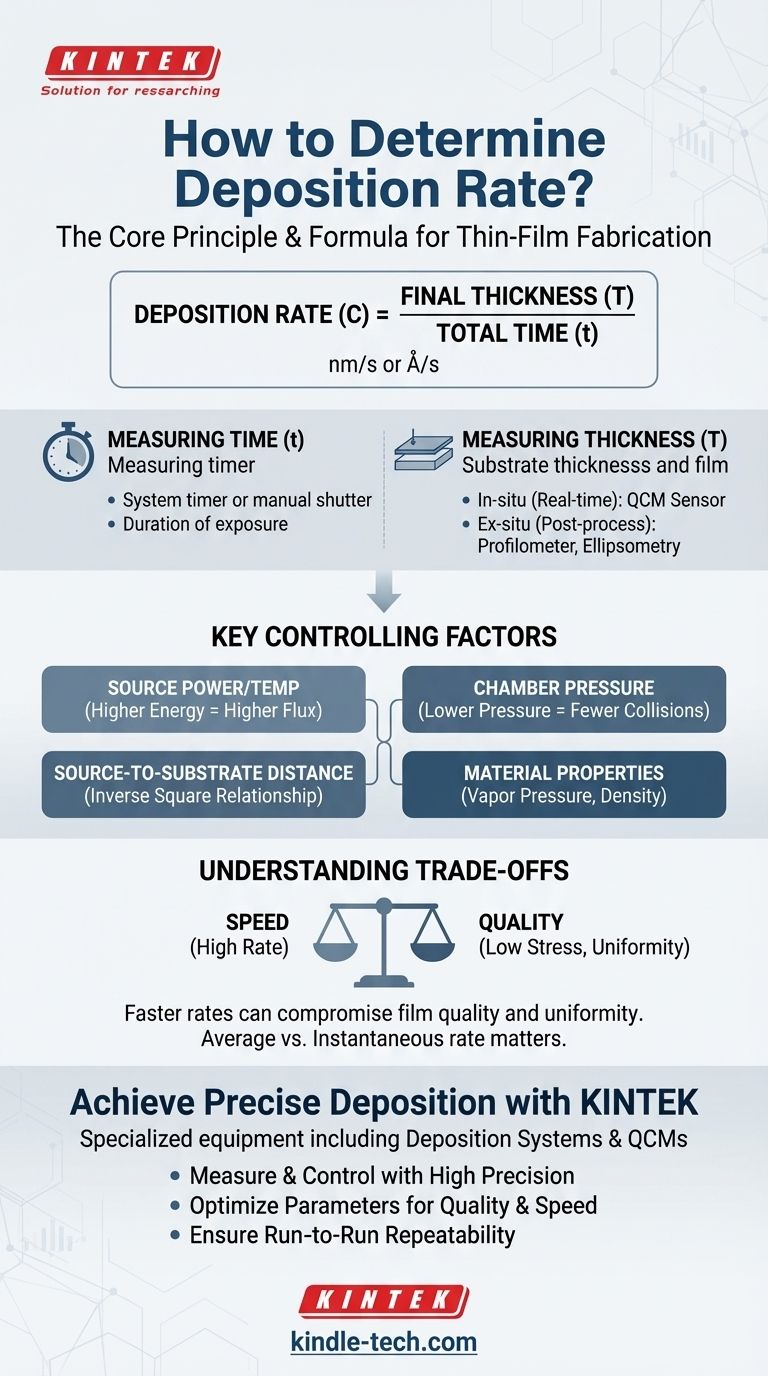

The deposition rate is determined by a simple and direct calculation. You divide the final thickness of the deposited film by the total time of the deposition process. This provides the average rate at which the material accumulated on your substrate.

While the core formula is

Rate = Thickness / Time, mastering your deposition process requires understanding how to accurately measure thickness and control the physical parameters that dictate the rate itself.

The Core Principle: Measuring Thickness and Time

To determine the deposition rate, you must have accurate values for the two primary inputs: the final film thickness and the duration of the deposition run.

The Fundamental Formula

The calculation itself is straightforward: C = T / t.

In this equation, C represents the deposition rate, T is the final thickness of the film, and t is the total deposition time. The resulting rate is typically expressed in units like nanometers per second (nm/s) or angstroms per second (Å/s).

Measuring Deposition Time (t)

This is the most direct measurement. Time is the duration for which the substrate is exposed to the flux of depositing material. This is typically controlled by a system timer or a manual shutter.

Measuring Film Thickness (T)

This is the most critical variable and requires specialized equipment. The method you choose depends on whether you need real-time data or a post-process measurement.

- In-situ (real-time) Measurement: A Quartz Crystal Microbalance (QCM) is often used inside the deposition chamber. The QCM sensor's oscillation frequency changes as mass is added, providing a real-time measurement of the accumulating thickness and instantaneous rate.

- Ex-situ (post-process) Measurement: After the deposition is complete, the film thickness can be measured with high precision using tools like a stylus profilometer, which physically measures the step height from the substrate to the film surface, or ellipsometry, which uses polarized light to determine thickness.

Key Factors That Control Your Deposition Rate

Simply calculating the rate after the fact is useful for characterization. However, true process control comes from understanding and manipulating the variables that influence it.

Source Power or Temperature

For processes like thermal evaporation or sputtering, the energy input to the source material is a primary driver. Higher power or temperature increases the flux of evaporated or sputtered atoms, leading to a higher deposition rate.

Chamber Pressure

The pressure of the vacuum chamber, particularly the partial pressure of background gases, affects the mean free path of the depositing atoms. Higher pressures can lead to more collisions, scattering the atoms and reducing the rate at the substrate.

Source-to-Substrate Distance

The geometry of your system is critical. As the distance between the material source and your substrate increases, the deposition rate will decrease, generally following an inverse square relationship.

Material Properties

Different materials deposit at vastly different rates under the same conditions. This is due to intrinsic properties like vapor pressure, density, and sputtering yield.

Understanding the Trade-offs

Optimizing for the highest possible rate is not always the best strategy. There are critical trade-offs between speed and quality.

Rate vs. Film Quality

Depositing material too quickly can result in a film with higher internal stress, poorer adhesion, or a less dense microstructure. A slower, more controlled deposition often yields higher-quality films.

Rate vs. Uniformity

A high deposition rate, often achieved by placing the substrate closer to the source, can reduce the uniformity of the film's thickness across the surface of the substrate. Greater source-to-substrate distance typically improves uniformity at the expense of the rate.

Average Rate vs. Instantaneous Rate

The formula T/t provides the average rate over the entire run. However, the instantaneous rate can fluctuate due to instabilities in source power or pressure. Only in-situ monitoring with a tool like a QCM can reveal these fluctuations.

Making the Right Choice for Your Goal

To effectively control your film deposition, align your approach with your primary objective.

- If your primary focus is process validation: Perform a test deposition, measure the film thickness afterward with a profilometer, and use the

T/tformula to establish a baseline average rate for a specific set of parameters. - If your primary focus is high-precision thickness control: Use an in-situ tool like a QCM to monitor the rate in real time, allowing you to close the shutter at the exact moment your target thickness is reached.

- If your primary focus is run-to-run repeatability: Calibrate your average deposition rate, then meticulously document and control all system parameters—power, pressure, time, and geometry—to ensure consistency.

Mastering your deposition rate is the foundation for reliable and high-quality thin-film fabrication.

Summary Table:

| Aspect | Key Point | Common Tool/Method |

|---|---|---|

| Core Formula | Rate = Final Thickness / Deposition Time | Basic calculation |

| Thickness Measurement | Critical for accuracy; in-situ or ex-situ | QCM (real-time), Profilometer (post-process) |

| Key Controlling Factors | Source power, chamber pressure, geometry | System parameter controls |

| Trade-off | Higher rate can mean lower film quality/uniformity | Process optimization |

Achieve precise and repeatable thin-film deposition with KINTEK.

Whether you are developing new materials or ensuring production consistency, accurately controlling your deposition rate is critical. KINTEK specializes in high-quality lab equipment, including deposition systems and monitoring tools like quartz crystal microbalances (QCMs), to help you:

- Measure and control deposition rates with high precision for reliable, high-quality films.

- Optimize your process parameters to balance speed, uniformity, and film quality.

- Ensure run-to-run repeatability with robust and reliable equipment.

Let our expertise support your laboratory's success. Contact KINTEK today to discuss your specific deposition needs and find the perfect solution for your lab.

Visual Guide

Related Products

- Inclined Rotary Plasma Enhanced Chemical Vapor Deposition PECVD Equipment Tube Furnace Machine

- RF PECVD System Radio Frequency Plasma-Enhanced Chemical Vapor Deposition RF PECVD

- Electron Beam Evaporation Coating Oxygen-Free Copper Crucible and Evaporation Boat

- Chemical Vapor Deposition CVD Equipment System Chamber Slide PECVD Tube Furnace with Liquid Gasifier PECVD Machine

- Laboratory CVD Boron Doped Diamond Materials

People Also Ask

- What is the process of PECVD in semiconductor? Enabling Low-Temperature Thin Film Deposition

- What is the difference between plasma CVD and thermal CVD? Choose the Right Method for Your Substrate

- How do PECVD systems improve DLC coatings on implants? Superior Durability and Biocompatibility Explained

- Can plasma enhanced CVD deposit metals? Why PECVD is rarely used for metal deposition

- What is the difference between PECVD and APCVD? Choose the Right CVD Method for Your Application