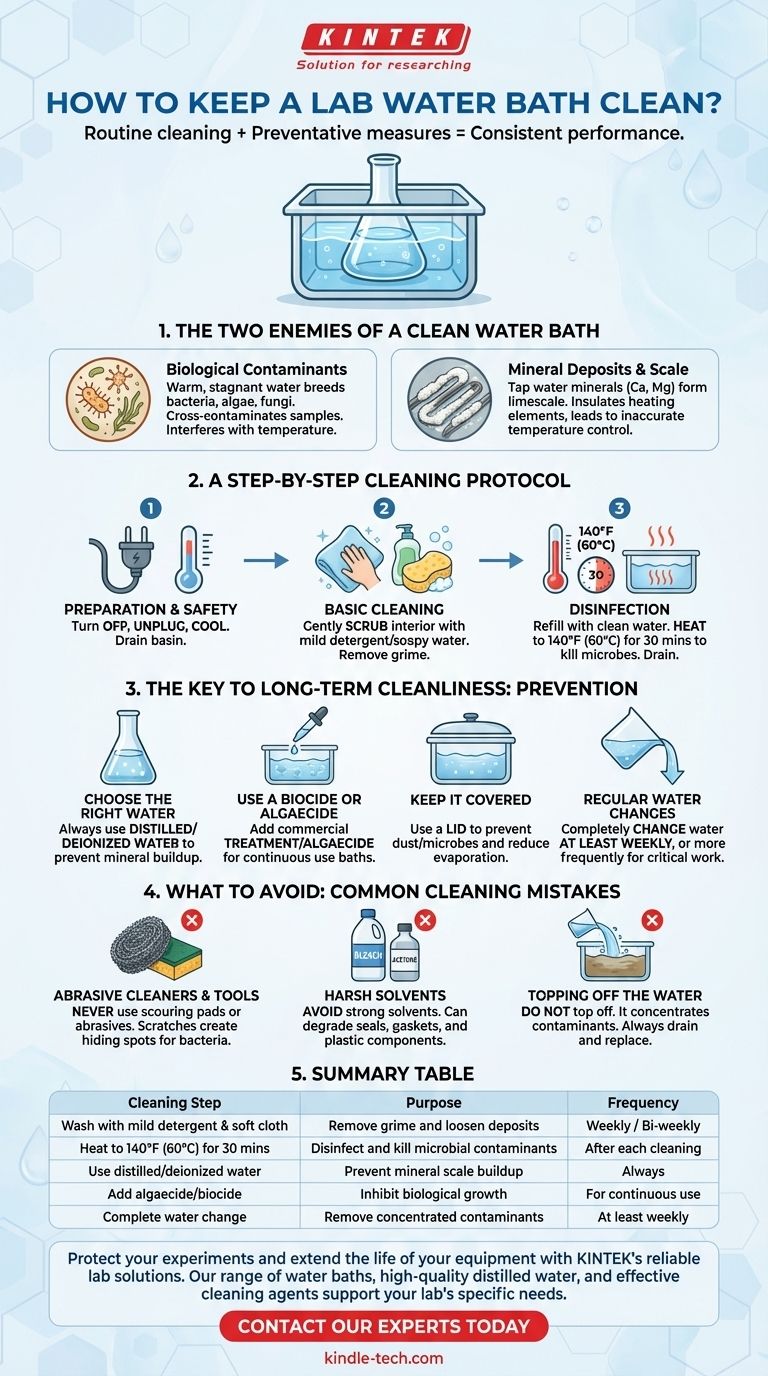

To keep a lab water bath clean, you must combine a routine physical cleaning schedule with preventative measures. The simplest effective method involves cleaning the basin with warm, soapy water and a soft cloth, followed by a disinfection step using water heated to 140°F (60°C) for at least 30 minutes to eliminate biological contaminants.

Maintaining a clean lab water bath isn't about occasional deep cleaning; it's a consistent preventative strategy that targets both biological growth and mineral deposits before they can compromise your experiments.

The Two Enemies of a Clean Water Bath

Understanding what you're fighting is the first step. Contamination in a water bath typically falls into two categories, each requiring a different approach.

Biological Contaminants

This is the most common issue. The warm, stagnant water is an ideal breeding ground for bacteria, algae, and fungi.

This growth can cross-contaminate your samples, interfere with temperature uniformity, and create unpleasant odors in the lab.

Mineral Deposits and Scale

When you use standard tap water, dissolved minerals like calcium and magnesium are left behind as the water evaporates.

These minerals form a hard, whitish crust known as limescale. Scale acts as an insulator, forcing the heating element to work harder and potentially leading to inaccurate temperature control.

A Step-by-Step Cleaning Protocol

Follow this simple but effective protocol on a weekly or bi-weekly basis, or whenever the water appears cloudy.

Preparation and Safety

First, ensure the unit is turned off and completely unplugged from the power source. Allow the water to cool to a safe temperature before draining the basin.

Basic Cleaning

Use a soft cloth or sponge with a mild detergent or soapy water to gently scrub all interior surfaces of the tank. This removes grime and loosens any mineral deposits.

Disinfection

After cleaning, refill the bath with clean water. Heat the unit to approximately 140°F (60°C) and hold it at that temperature for at least 30 minutes to kill most microbial contaminants. Drain the water once finished.

The Key to Long-Term Cleanliness: Prevention

Reactive cleaning is inefficient. A proactive strategy is far more effective and saves significant time.

Choose the Right Water

Always use distilled or deionized water. This is the single most important step to prevent mineral buildup and limescale, which drastically simplifies cleaning.

Use a Biocide or Algaecide

For baths that run continuously, add a commercial water bath treatment or algaecide. These products are specifically designed to inhibit the growth of bacteria and algae, keeping the water clear for weeks.

Keep it Covered

Use a lid whenever possible. A cover prevents airborne dust and microbes from settling in the water and also reduces evaporation, which concentrates mineral content.

Perform Regular Water Changes

Even with preventative measures, you should completely change the water at least once a week. For critical applications, change it more frequently.

What to Avoid: Common Cleaning Mistakes

Avoiding bad practices is as important as adopting good ones. Certain shortcuts can damage your equipment.

Abrasive Cleaners and Tools

Never use scouring pads, steel wool, or abrasive chemical cleaners. These will scratch the stainless steel basin, creating microscopic crevices where bacteria can hide and corrosion can begin.

Harsh Solvents

Avoid using strong solvents like acetone or bleach (unless heavily diluted and thoroughly rinsed) as they can degrade seals, gaskets, and plastic components of the water bath.

Topping Off the Water

Constantly topping off an old batch of water just concentrates the contaminants and minerals. Always drain and replace the water completely.

Making the Right Choice for Your Goal

Your maintenance strategy should align with your lab's specific needs and the sensitivity of your work.

- If your primary focus is preventing biological contamination: Prioritize regular water changes and the consistent use of a commercial algaecide.

- If your primary focus is equipment longevity and temperature accuracy: Insist on the exclusive use of distilled or deionized water to prevent insulating scale buildup.

- If your primary focus is general-purpose, infrequent use: A simple protocol of cleaning with soapy water and drying thoroughly after each use is sufficient.

A proactive approach to water bath maintenance protects your equipment and ensures the integrity of your results.

Summary Table:

| Cleaning Step | Purpose | Frequency |

|---|---|---|

| Wash with mild detergent & soft cloth | Remove grime and loosen deposits | Weekly / Bi-weekly |

| Heat to 140°F (60°C) for 30 mins | Disinfect and kill microbial contaminants | After each cleaning |

| Use distilled/deionized water | Prevent mineral scale buildup | Always |

| Add algaecide/biocide | Inhibit biological growth | For continuous use |

| Complete water change | Remove concentrated contaminants | At least weekly |

Protect your experiments and extend the life of your equipment with KINTEK's reliable lab solutions. Our range of water baths and essential consumables, like high-quality distilled water and effective cleaning agents, are designed to support your lab's specific needs. Ensure accuracy and prevent contamination—contact our experts today to find the perfect maintenance products for your laboratory!

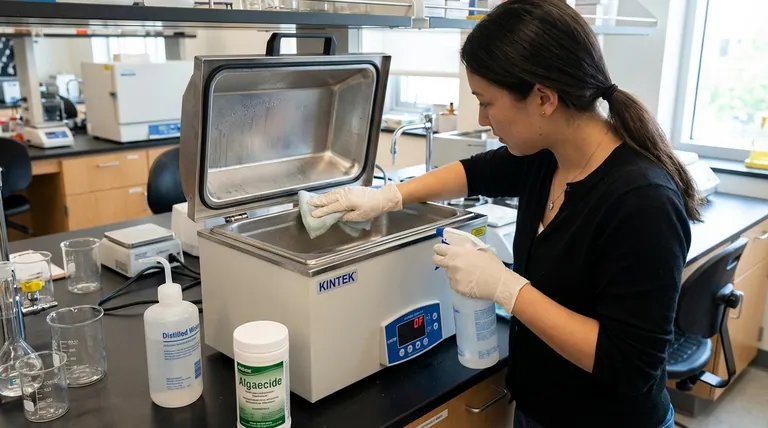

Visual Guide

Related Products

- 50L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

- High Temperature Constant Temperature Heating Circulator Water Bath Chiller Circulator for Reaction Bath

- 30L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

- 10L Chilling Circulator Cooling Water Bath Low Temperature Constant Temperature Reaction Bath

- 20L Heating Chilling Circulator Cooling Water Bath Circulator for High and Low Temperature Constant Temperature Reaction

People Also Ask

- How does a thermostatic water bath function in ODS steel corrosion tests? Ensure Precise Bio-Simulation Accuracy

- Why is it necessary to configure a thermostatic water bath or ice bath during Ni–Cr–P electrodeposition?

- What role does constant temperature refrigeration equipment play in radioactive leaching? Ensuring Deep-Sea Safety

- Which is a proper technique of cleaning water baths in the laboratory? A Step-by-Step Guide to Prevent Contamination

- Why is a high-precision digital display heating unit necessary for phenol catalytic oxidation? Optimize Reaction Yield

- What is the purpose of using a constant temperature circulating water jacket during the degradation of Cefoperazone?

- Why is a low-temperature cooling solution necessary for nanoparticle toxicity? Ensure Scientific Accuracy & Stability

- Why is constant temperature control required for CGDE? Ensure Precision in Electrolyte Conductivity Measurement