Mixing rubber compounds is a critical process that transforms raw polymers and additives into a uniform material with specific physical properties. The two primary industrial methods for accomplishing this are mixing on an open two-roll mill or mixing within a more complex internal mixer, such as a Banbury mixer.

The choice between an open mill and an internal mixer is not about which is "better," but which is the right tool for the job. It's a strategic decision that balances the need for small-batch flexibility against the demands of high-volume efficiency and consistency.

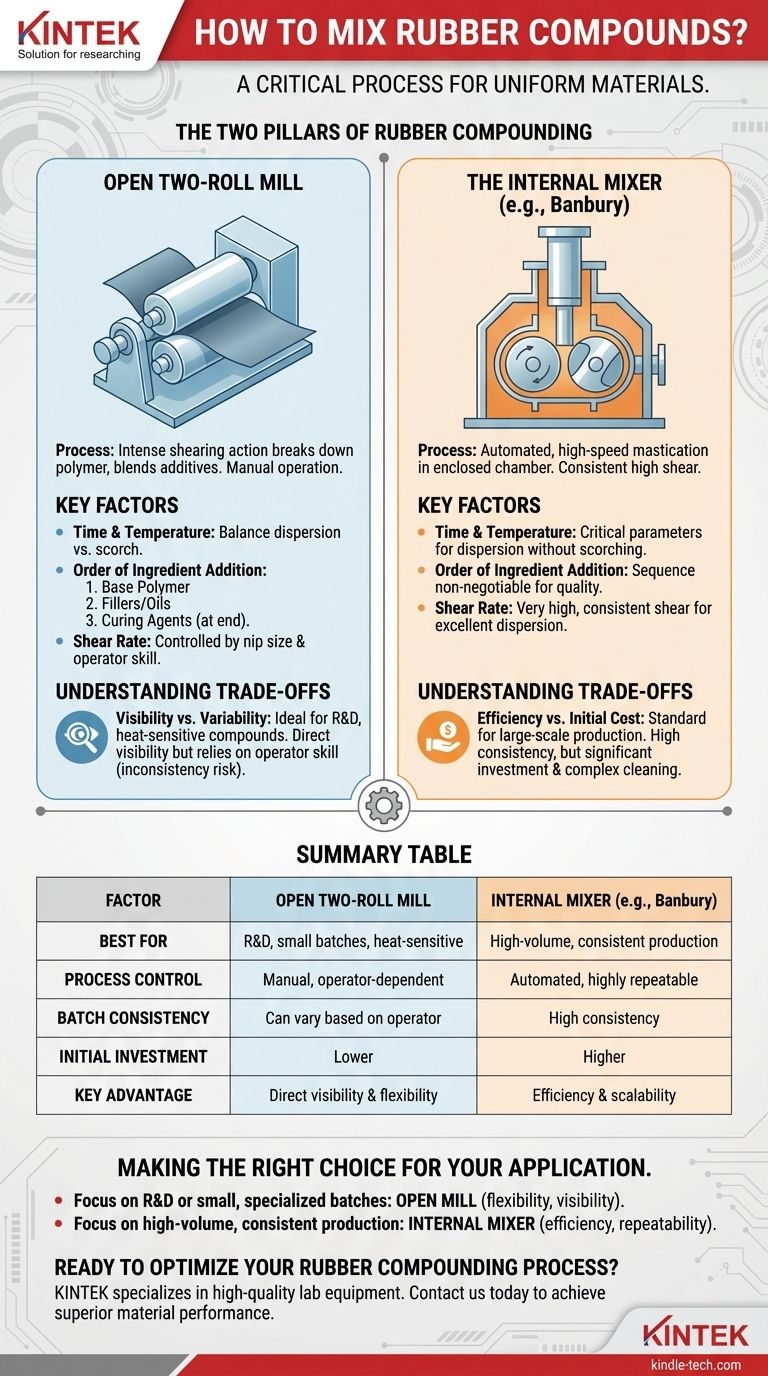

The Two Pillars of Rubber Compounding

Understanding how each piece of equipment works is the first step in selecting the correct process for your application. Each method imparts shear and energy into the materials differently, directly impacting the final compound.

The Open Two-Roll Mill

An open mill is the classic, foundational tool for rubber mixing. It consists of two large, counter-rotating horizontal rolls.

The gap between these rolls, known as the nip, can be precisely adjusted. As the rubber is passed through the nip, the intense shearing action breaks down the polymer and blends in the various additives.

This method is highly manual. An operator repeatedly cuts the rubber sheet off one roll and feeds it back into the nip to ensure a homogenous mix.

The Internal Mixer

An internal mixer, like the industry-standard Banbury mixer, performs the same function but in a completely enclosed chamber.

Inside the chamber, two specially shaped rotors turn toward each other, masticating the rubber. A ram pushes down from the top, ensuring the materials are constantly forced into the high-shear zone between the rotors.

This process is automated and operates at much higher speeds and pressures than an open mill, allowing for significantly larger batch sizes.

Key Factors in the Mixing Process

Regardless of the equipment used, the quality of the final rubber compound depends on the precise control of a few key variables.

Time and Temperature

These are the most critical parameters. The goal is to input enough energy to achieve good dispersion of fillers without raising the temperature so high that the compound begins to scorch (prematurely cure).

Order of Ingredient Addition

The sequence of adding materials is non-negotiable for quality.

First, the base polymer is masticated to break down its molecular weight. Next, fillers and processing oils are added. Finally, the curing agents (like sulfur) are added at the very end of the cycle, typically at a lower temperature to prevent scorching.

Shear Rate

Shear is the force that blends the ingredients. Internal mixers generate very high, consistent shear, leading to excellent dispersion in a short time.

On an open mill, the shear is controlled by the nip size and the operator's skill in cutting and blending the material band.

Understanding the Trade-offs

Each method presents a distinct set of advantages and disadvantages that must be weighed against your operational goals.

Open Mill: Visibility vs. Variability

The greatest advantage of an open mill is direct visibility. An experienced operator can see the compound and make real-time adjustments to the process. This makes it ideal for developing new formulations and for heat-sensitive compounds.

However, this reliance on operator skill is also its main drawback. It can lead to significant batch-to-batch inconsistency and presents greater safety risks than an enclosed system.

Internal Mixer: Efficiency vs. Initial Cost

The internal mixer is built for efficiency and repeatability. Its automated, high-speed process produces highly consistent batches, making it the standard for any large-scale production.

The primary disadvantages are the significant capital investment required and the time-consuming process of cleaning the chamber between different compound formulations. It is not practical for very small, experimental batches.

Making the Right Choice for Your Application

Selecting the correct mixing method is fundamental to achieving your desired product quality and manufacturing efficiency.

- If your primary focus is research and development or small, specialized batches: The open mill offers the necessary flexibility and direct process visibility.

- If your primary focus is high-volume, consistent production: The internal mixer is the definitive choice for its efficiency, control, and repeatability.

Ultimately, mastering rubber compounding lies in selecting the method that best aligns with your specific production scale and quality objectives.

Summary Table:

| Factor | Open Two-Roll Mill | Internal Mixer (e.g., Banbury) |

|---|---|---|

| Best For | R&D, small batches, heat-sensitive compounds | High-volume, consistent production |

| Process Control | Manual, operator-dependent | Automated, highly repeatable |

| Batch Consistency | Can vary based on operator skill | High consistency |

| Initial Investment | Lower | Higher |

| Key Advantage | Direct visibility and flexibility | Efficiency and scalability |

Ready to Optimize Your Rubber Compounding Process?

Choosing the right mixing equipment is critical for achieving the desired properties and efficiency in your rubber products. Whether you are developing new formulations in the lab or scaling up for mass production, having reliable equipment is key.

At KINTEK, we specialize in providing high-quality lab equipment and consumables for all your laboratory needs. Our expertise can help you select the perfect mixing solution—from versatile open mills for R&D to high-efficiency internal mixers for production—ensuring you get consistent, high-quality results.

Contact us today using the form below to discuss how we can support your compounding process and help you achieve superior material performance.

Visual Guide

Related Products

- Lab Internal Rubber Mixer Rubber Kneader Machine for Mixing and Kneading

- Laboratory Disc Rotary Mixer for Efficient Sample Mixing and Homogenization

- Laboratory Vortex Mixer Orbital Shaker Multifunctional Rotation Oscillation Mixer

- Laboratory Oscillating Orbital Shaker

- High Shear Homogenizer for Pharmaceutical and Cosmetic Applications

People Also Ask

- How do you recycle rubber waste? Unlock the 3 Key Methods for Tire & Rubber Recycling

- What is the use of internal mixer? Boost Polymer Mixing Efficiency & Quality

- What is the process of mixing rubber compounds? A Guide to Creating Uniform, High-Performance Materials

- Why are stirring or homogenizing devices essential in phase inversion? Achieve Perfect Photocatalytic Membrane Dispersion

- What is the mixing process of rubber? Master the Stages for Superior Compound Quality