No, a muffle furnace is not an oven. While both are used for thermal processing, they are distinct pieces of equipment designed for fundamentally different purposes and temperature ranges. Confusing the two can lead to failed processes, damaged samples, and significant safety risks.

The core difference lies in temperature and isolation. An oven is for lower-temperature drying and heating, typically using circulated hot air. A muffle furnace is a specialized tool for reaching extremely high temperatures while isolating the sample from direct contact with the heating elements.

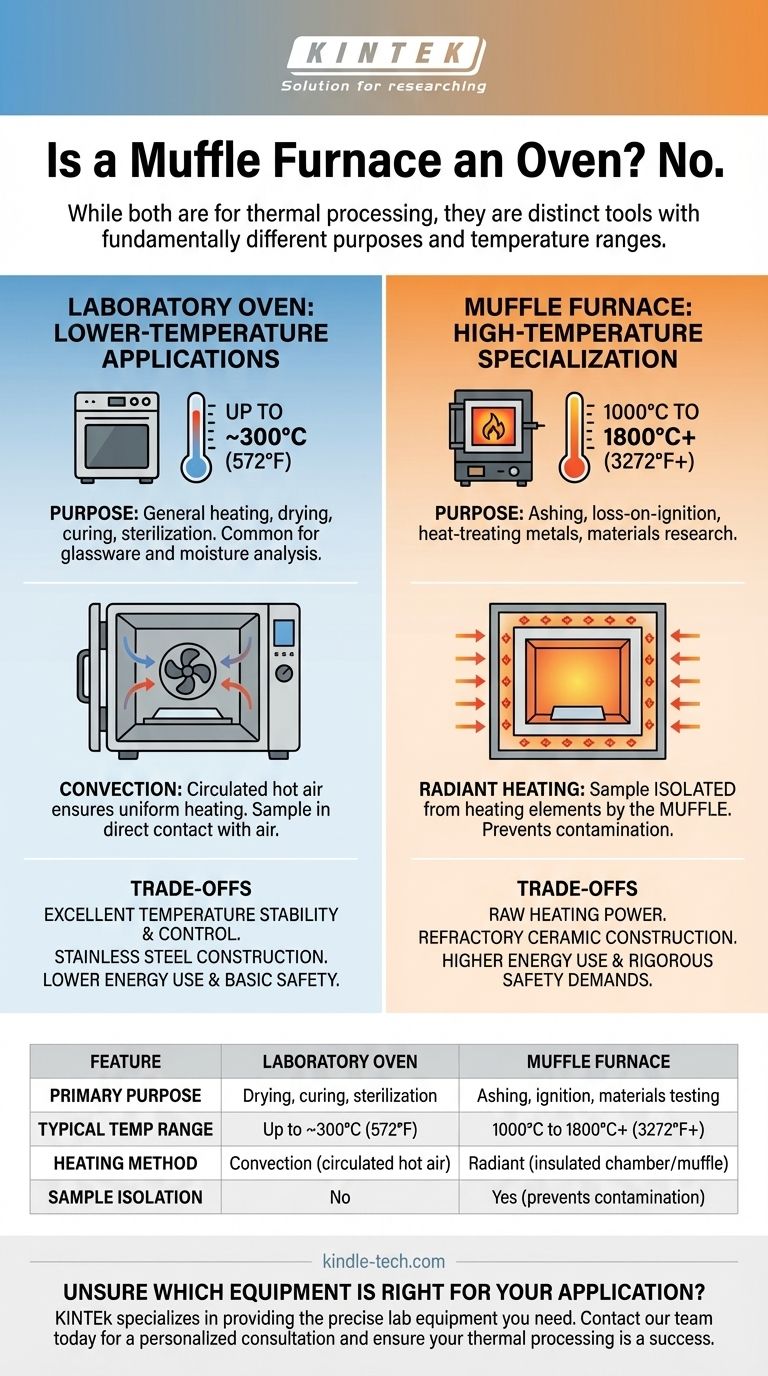

The Defining Factor: Temperature Range and Purpose

The most immediate distinction between an oven and a muffle furnace is their operational temperature range, which dictates their intended use.

Ovens: Lower-Temperature Applications

Laboratory ovens typically operate from slightly above ambient temperature up to around 300°C (572°F).

Their purpose is for general heating and drying. Common applications include drying glassware, moisture content analysis, curing materials, or gentle sterilization.

Muffle Furnaces: High-Temperature Specialization

Muffle furnaces are designed to operate at much higher temperatures, often starting around 1000°C and capable of reaching 1800°C (3272°F) or more.

They are used for specialized processes that require extreme heat, such as ashing organic materials, loss-on-ignition analysis, heat-treating metals, or materials research.

How They Work: The "Muffle" Is Key

The names themselves hint at the crucial difference in their internal mechanics and design philosophy.

The Insulating "Muffle" Chamber

A muffle furnace contains heating elements that heat an insulated inner chamber—the muffle.

This muffle serves as a barrier, separating the sample from the raw heating elements. This prevents contamination from combustion byproducts (in older fuel-fired models) and protects the sample from direct, uneven thermal radiation. The sample is heated uniformly by the surrounding hot chamber walls.

The Convection Oven

Most laboratory ovens, by contrast, use a fan to actively circulate heated air.

This convection process ensures uniform temperature distribution throughout the chamber, but it means the sample is in direct contact with the heating medium (air) and whatever impurities it may carry.

Understanding the Trade-offs

Choosing between these tools involves understanding their inherent design limitations and strengths.

Temperature Control vs. Raw Power

Ovens provide excellent temperature stability and precise control within their lower operating range.

Muffle furnaces are built for raw heating power. While modern controllers are very accurate, their primary design focus is on achieving and sustaining extreme temperatures, not necessarily fine-tuning a process at 150°C.

Material Construction and Energy Use

An oven is typically constructed from stainless steel with basic insulation. A furnace requires heavy-duty refractory ceramics and thick, multi-layered insulation to contain its intense heat.

This robust construction means muffle furnaces are significantly more expensive to purchase and consume far more energy to operate.

Safety and Operational Demands

Operating a 200°C oven requires basic safety precautions. Operating a 1200°C furnace demands rigorous safety protocols, specialized personal protective equipment (PPE), and awareness of severe burn risks.

Making the Right Choice for Your Application

Selecting the correct instrument is critical for procedural success, safety, and efficiency.

- If your primary focus is drying, curing, or general heating below 300°C: A standard laboratory oven is the correct, efficient, and cost-effective tool.

- If your primary focus is ashing, melting, or materials testing at temperatures above 1000°C: A muffle furnace is the only appropriate instrument for the task.

- If your primary focus is protecting a sample from direct heating element radiation: The furnace's muffle design is essential, making it the superior choice even for some specialized lower-temperature applications.

Ultimately, understanding that a furnace is a specialized high-temperature instrument, not simply a more powerful oven, is the key to making the right decision.

Summary Table:

| Feature | Laboratory Oven | Muffle Furnace |

|---|---|---|

| Primary Purpose | Drying, curing, sterilization | Ashing, ignition, materials testing |

| Typical Temp Range | Up to ~300°C (572°F) | 1000°C to 1800°C+ (3272°F+) |

| Heating Method | Convection (circulated hot air) | Radiant (insulated chamber/muffle) |

| Sample Isolation | No | Yes (prevents contamination) |

Unsure which equipment is right for your application?

KINTEK specializes in providing the precise lab equipment you need. Whether your process requires the gentle, uniform heat of a laboratory oven or the extreme temperatures of a muffle furnace, our experts can help you select the perfect solution for your laboratory's efficiency, safety, and accuracy.

Contact our team today for a personalized consultation and ensure your thermal processing is a success.

Visual Guide

Related Products

- Laboratory Muffle Oven Furnace Bottom Lifting Muffle Furnace

- 1400℃ Muffle Oven Furnace for Laboratory

- 1700℃ Muffle Oven Furnace for Laboratory

- 1800℃ Muffle Oven Furnace for Laboratory

- 1400℃ Laboratory High Temperature Tube Furnace with Alumina Tube

People Also Ask

- What is an example of quenching? Achieve Optimal Hardness with Precise Cooling

- How does quenching work chemistry? Mastering the Atomic Race for Harder Steel

- What are the applications of muffle furnace in pharmaceutical industry? Ensure Drug Purity and Quality

- What is the temperature of furnace exhaust? A Key Indicator of Efficiency and Safety

- What are muffle furnaces used for? Achieve Pure, High-Temperature Processing